Shield cable

A shielded cable, a new technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

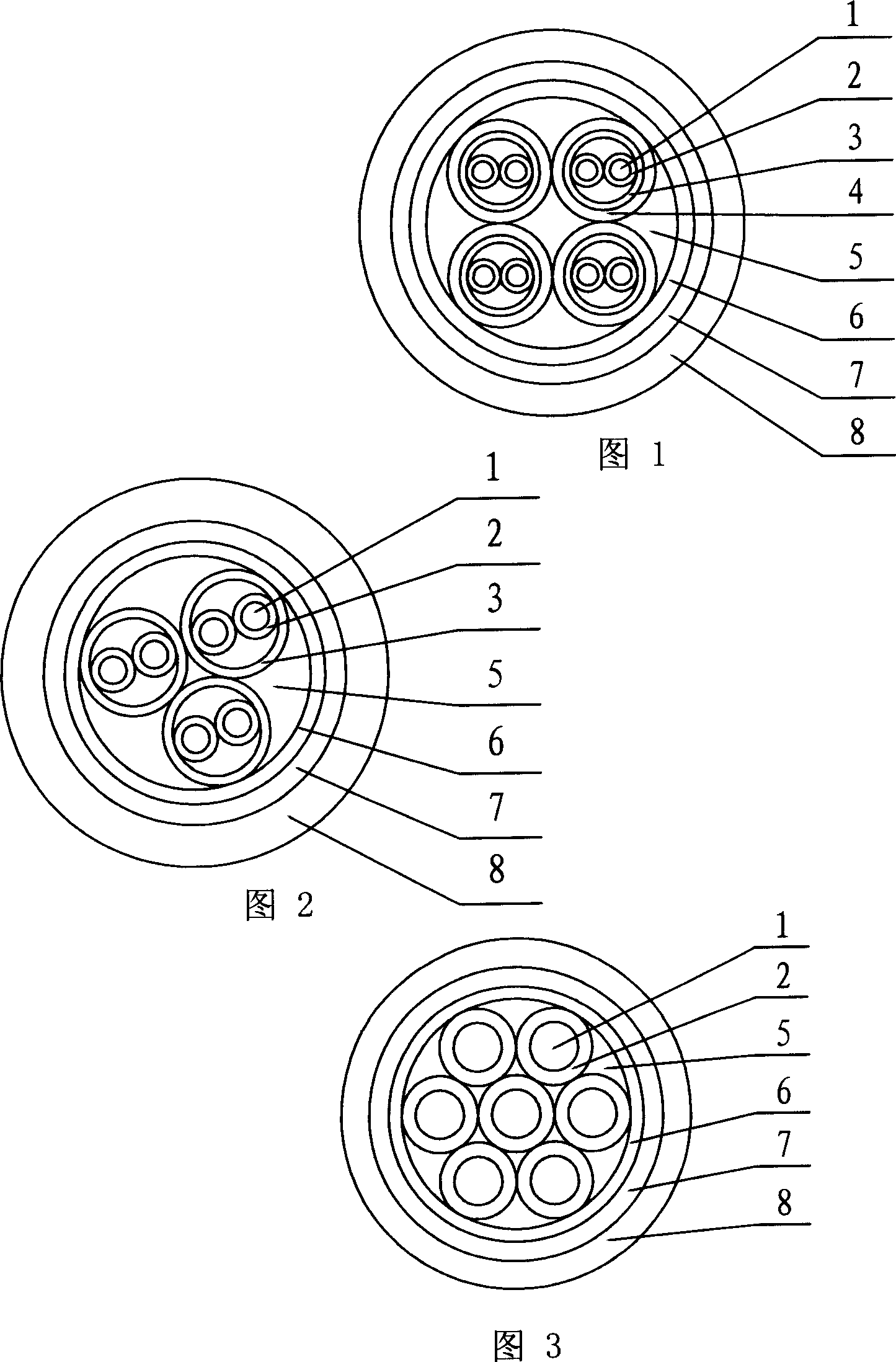

[0013] As shown in Figure 1, the outer surface of the oxygen-free copper wire as the conductor 1 is extruded with a polyvinyl chloride (or polyethylene, cross-linked polyethylene) insulation layer 2 to form an insulated core, and two insulated cores are twisted into a pair. For the twisted wire group, the polyester tape wrapping layer 3 and the braided copper-clad aluminum or copper-clad aluminum alloy wire sub-shielding layer 4 are wound on the twisted wire group. The twisted pair with tape layer 3 and sub-shield layer 4 is used to form a cable, and at the same time, PP filling rope or non-alkali glass filling rope is used as filler 5, and polyester tape tape layer 6 is wrapped around it. Copper-clad aluminum or copper-clad aluminum alloy wire overall shielding layer 7 is braided on the belt layer 6, and an outer sheath 8 of polyvinyl chloride or halogen-free low-smoke flame-retardant polyolefin is extruded on the overall shielding layer 7.

Embodiment 2

[0015] As shown in Figure 2, the outer surface of the conductor 1 is made of oxygen-free copper wire, and the insulating layer 2 of polyvinyl chloride (or polyethylene, cross-linked polyethylene) is extruded to form an insulated core, and two insulated cores are twisted into a pair. For the twisted wire group, wrap the polyester tape wrapping layer 3 on the twisted wire group. The twisted pair with the tape layer 3 is used to form a cable, and at the same time, the filler 5 is filled with PP filling rope or alkali-free glass filling rope, and the polyester tape is wrapped around the tape layer 6 . Copper-clad aluminum or copper-clad aluminum alloy wire overall shielding layer 7 is braided on the belt layer 6, and an outer sheath 8 of polyvinyl chloride or halogen-free low-smoke flame-retardant polyolefin is extruded on the overall shielding layer 7.

Embodiment 3

[0017] As shown in Figure 3, the outer surface of the oxygen-free copper wire as the conductor 1 is extruded with a polyvinyl chloride (or polyethylene, cross-linked polyethylene) insulating layer 2 to form an insulated core, and multiple insulated cores are directly cabled. , and at the same time use PP filling rope or non-alkali glass filling rope as filler 5 to fill, and wrap polyester tape wrapping layer 6 around. Copper-clad aluminum or copper-clad aluminum alloy wire overall shielding layer 7 is braided on the belt layer 6, and an outer sheath 8 of polyvinyl chloride or halogen-free low-smoke flame-retardant polyolefin is extruded on the overall shielding layer 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com