Waste gas purifying apparatus

A technology of exhaust gas purification device and catalyst, which is applied in the direction of exhaust device, noise reduction device, engine components, etc. It can solve the problems of impossible precise adjustment and limited degree of freedom, and achieve easy output adjustment, improved degree of freedom, accuracy and high efficiency Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

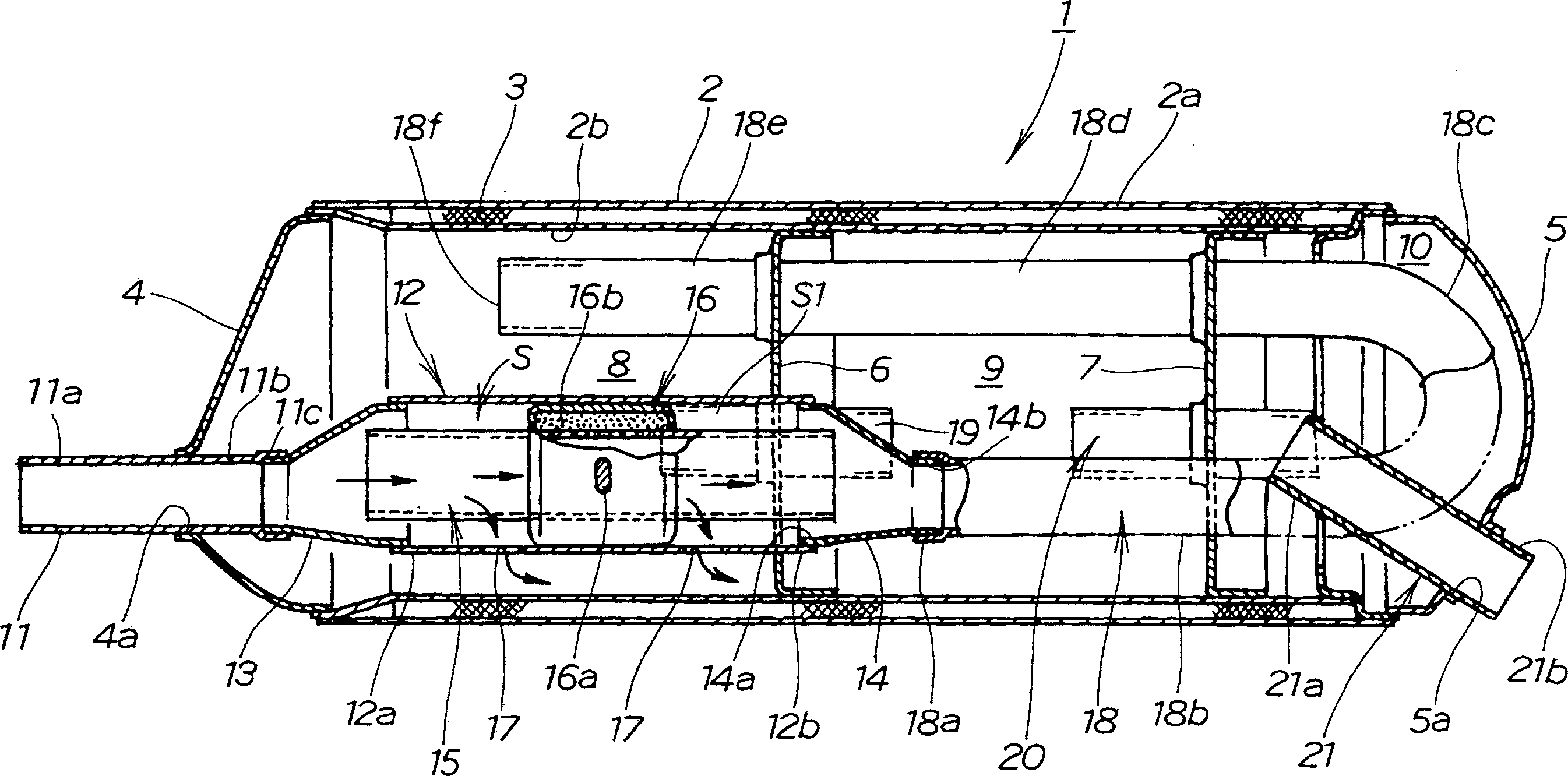

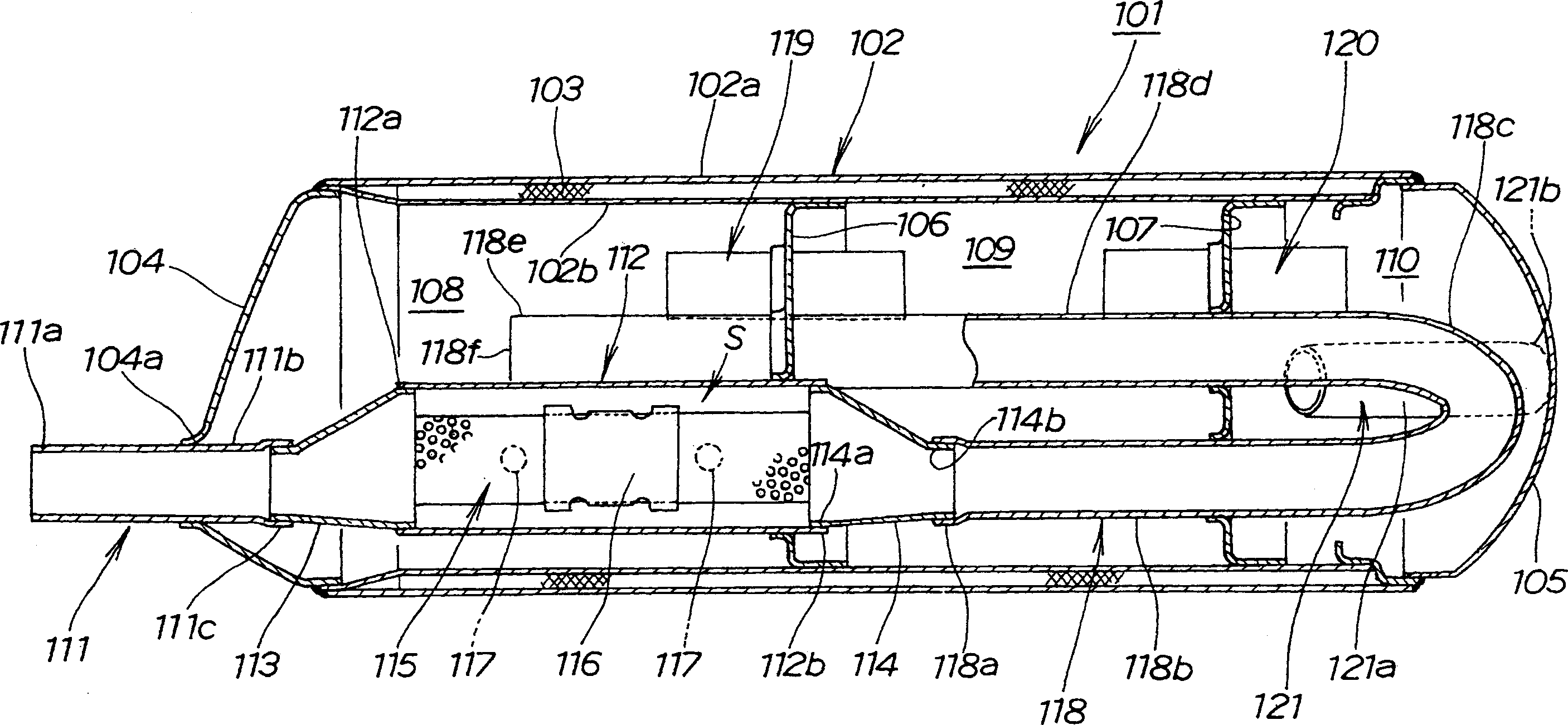

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, "front", "rear", "left", "right", "up", and "down" are directions seen from the driver's point of view, Fr indicates the front side, Rr indicates the rear side, and L indicates the left side side, R means the right side. Furthermore, the drawings should be viewed in the direction of the reference numerals.

[0032] figure 1 It is a left side view showing an example of a motorcycle using the present invention.

[0033] Next, the schematic structure of a two-wheeled motor vehicle will be described using this figure.

[0034] Automatic two-wheel vehicle 210 is a kind of small automatic two-wheel vehicle, and it is mainly made of following parts: vehicle frame 211; Front fork 212 that is installed on the head pipe 211a of vehicle frame 211; ; the handle 214 that is connected on the front fork 212; the power unit 215 that is installed in the rear portion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com