Cupronickel condensation tube production process using disk stretch

A process method and technology of condensing tubes, which are applied in the field of making cupronickel condensing tubes by coil drawing, can solve the problems of increased number of stretching passes, tedious process, unsatisfactory and other problems, so as to reduce the process of process, reduce production cost and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

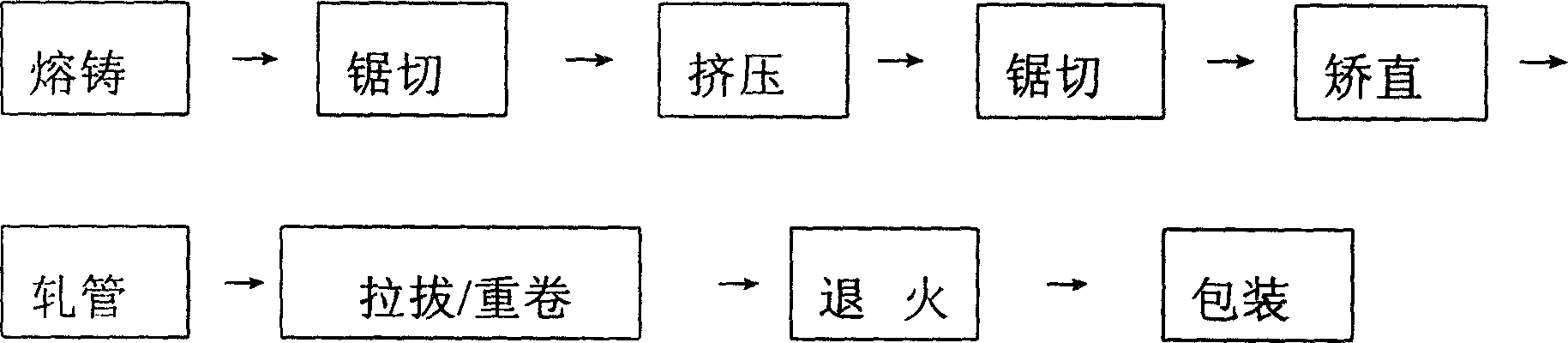

Method used

Image

Examples

Embodiment 1

[0017] A soft-state B 10-axis roll-shaped nickel-copper condenser tube, specification: φ10×0.6mm, average outer diameter allowable deviation ±0.05mm, wall thickness allowable deviation ±0.05mm, Rp 0.2: 90~105Mpa, Rm≥290Mpa, A≥ 30%, the coil weight is 80-120Kg / roll, and the defect points are less than 5 points per roll.

[0018] 1. Melting and casting: casting into ingots with a specification of φ245mm. Use a coreless induction furnace for melting, casting temperature: 1250°C, casting speed: 2.5m / h, and its chemical composition complies with GB5234-2001.

[0019] 2. Extrusion: Extruded into a tube blank of φ80×10mm. Extrusion is carried out with an extruder and a matching mandrel, and the water seal peeling method is adopted in the extrusion process; the heated ingot is pushed into the extrusion barrel of the extruder, and the extruded ingot is extruded by the extrusion shaft and flows out through the mold outlet, and the mold The outlet is connected to a water tank full of w...

Embodiment 2

[0028] A hard B 10 straight white copper condenser tube, specification φ6.35×0.51mm, tolerance tolerance of outer diameter ±0.051mm, tolerance tolerance of wall thickness ±0.038mm, Rp0.5>240Mpa, Rm>310Mpa, straight Degree <12mm / 3000mm.

[0029] 1. Melting and casting: casting into ingots with a specification of φ245mm. Use a coreless induction furnace for melting, casting temperature: 1285°C, casting speed: 3m / h, and its chemical composition complies with GB5234-2001.

[0030]2. Extrusion: Extruded into a tube blank of φ80×10mm. Use extruder and supporting mandrel to extrude, adopt the mode of water seal peeling in the extruding process, with embodiment 1. The heating temperature of the extrusion process: 960°C, the extrusion speed: 42mm / s, the extrusion ratio: 21, and the excess thickness: 32mm.

[0031] 3. Sawing: Use a sawing machine to cut off the head and tail.

[0032] 4. Straightening: Use horizontal straightening to straighten.

[0033] 5. Rolling: use a pipe roll...

Embodiment 3

[0038] A soft-state B 10 mosquito-repellent coil-shaped cupronickel condenser tube, specification φ6.35×0.51mm, tolerance tolerance of outer diameter ±0.051mm, tolerance tolerance of wall thickness ±0.038mm, Rp0.2: 90~105Mpa, Rm>290Mpa, A≥30%, the length of the mosquito coil is 15mm, and the allowable deviation of the length is 0-300mm.

[0039] 1. Melting and casting: casting into ingots with a specification of φ245mm. Use a coreless induction furnace for melting, casting temperature: 1320°C, casting speed: 3.5m / h, and its chemical composition complies with GB5234-2001.

[0040] 2. Extrusion: Extruded into a tube blank of φ80×10mm. Use extruder and supporting mandrel to extrude, adopt the mode of water seal peeling in the extruding process, with embodiment 1. Heating temperature of the extrusion process: 1000°C, extrusion speed: 50mm / s, extrusion ratio: 21, excess thickness: 40mm.

[0041] 3. Sawing: Use a sawing machine to cut off the head and tail.

[0042] 4. Straighte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com