Method and device for continuous production of copper pipes

A technology for copper tubes and equipment, applied in the field of continuous production of copper tubes, can solve the problems of high production labor intensity, increase product production costs, low production efficiency, etc., achieve continuous production, improve product yield, and reduce occupied area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

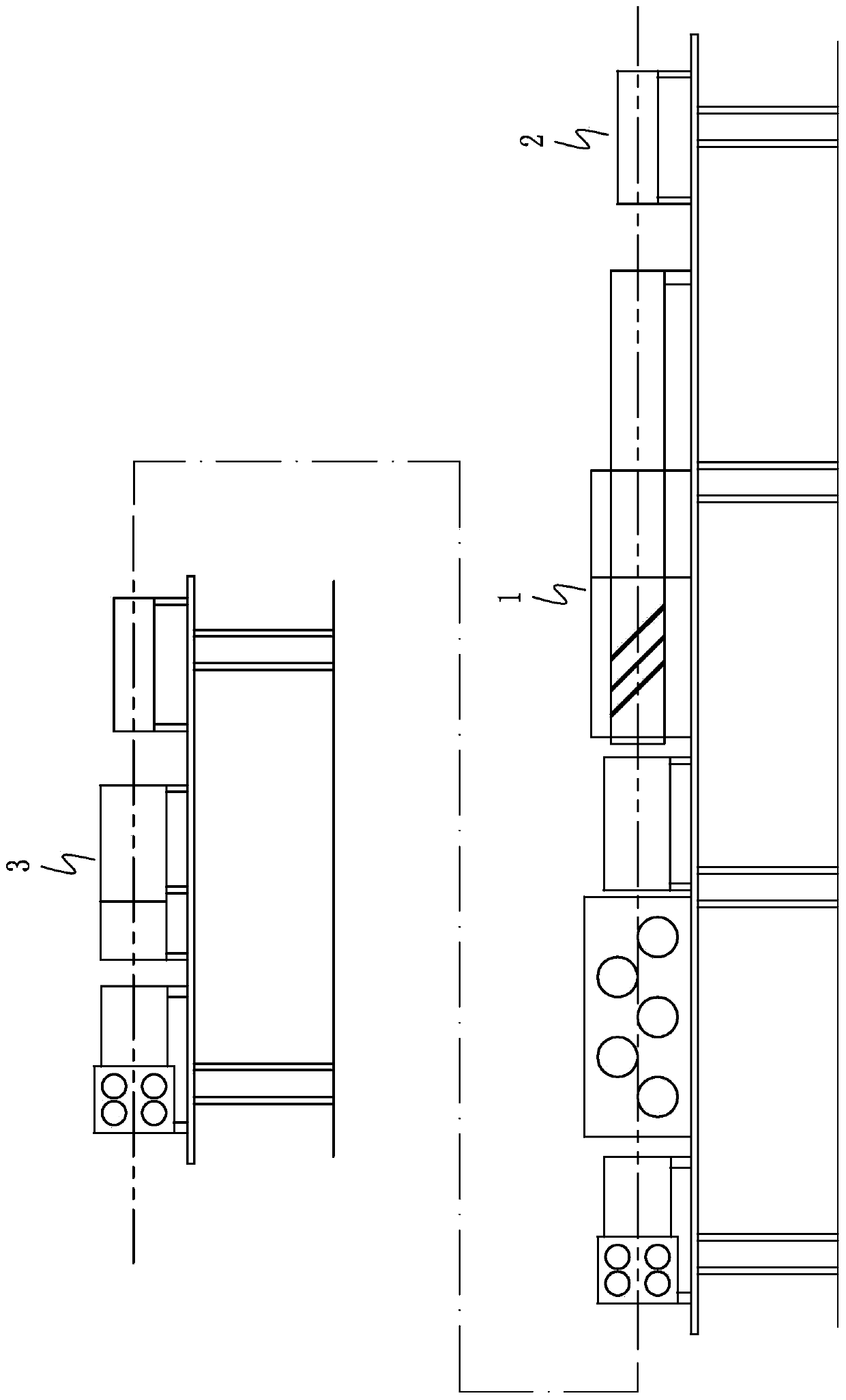

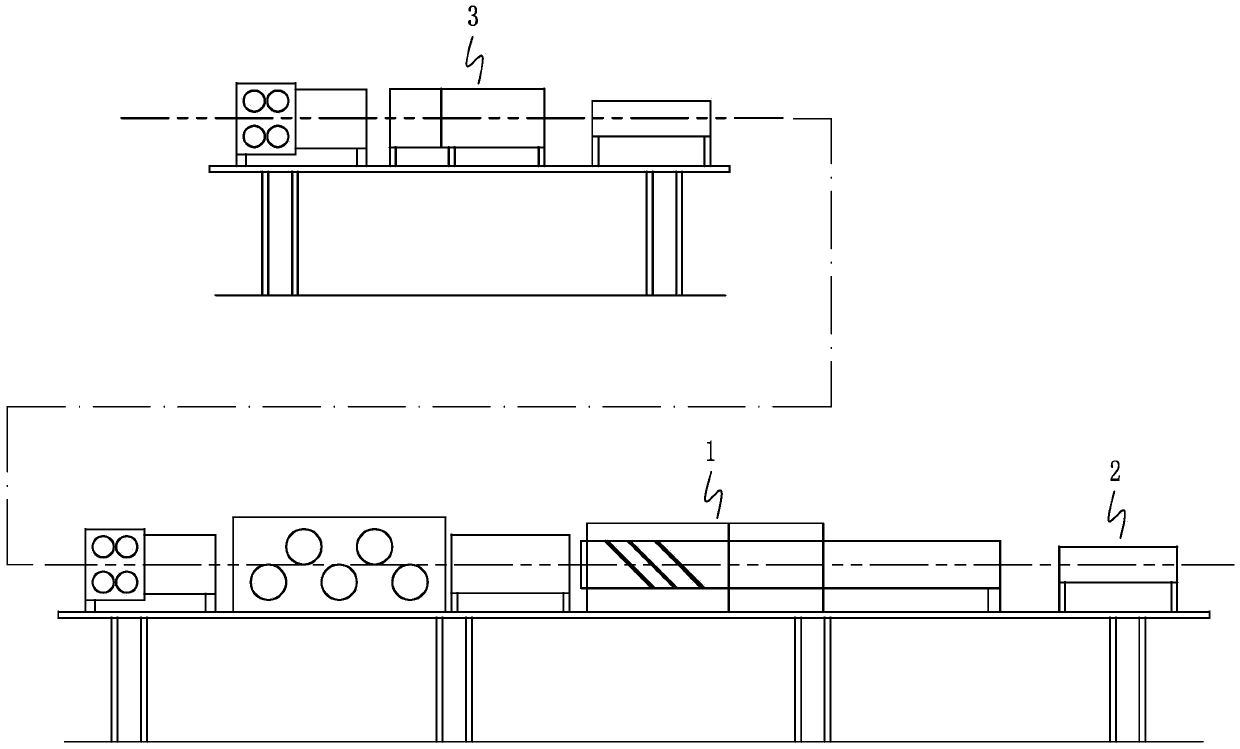

[0015] Such as figure 1 As shown, a method for realizing the continuous production of copper tubes adds a welding process after the traditional two-roller periodic cold rolling process, welds the rolled and formed copper tubes in sequence, and then performs at least one annealing followed by coil stretching. By welding multiple copper tubes into one copper tube, it is convenient for subsequent continuous stretching. Depending on the degree of stretching of the copper tube, one or more stretches may be performed. When welding, the end of the copper pipe can be ground and smoothed as required.

[0016] In order to prevent the oxidation of the inner surface of the copper tube after the coil is stretched, the copper tube after the coil can be filled with inert gas and plugged at both ends to prevent the inner surface of the copper tube from being oxidized.

[0017] In order to prevent the oxidation of the outer surface of the copper tube during annealing, hydrogen and nitrogen m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com