Optical fiber end surface grinding device

An end face and tooling technology, used in grinding devices, grinding machine tools, optics, etc., can solve problems such as non-parallel, inconvenient automation, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

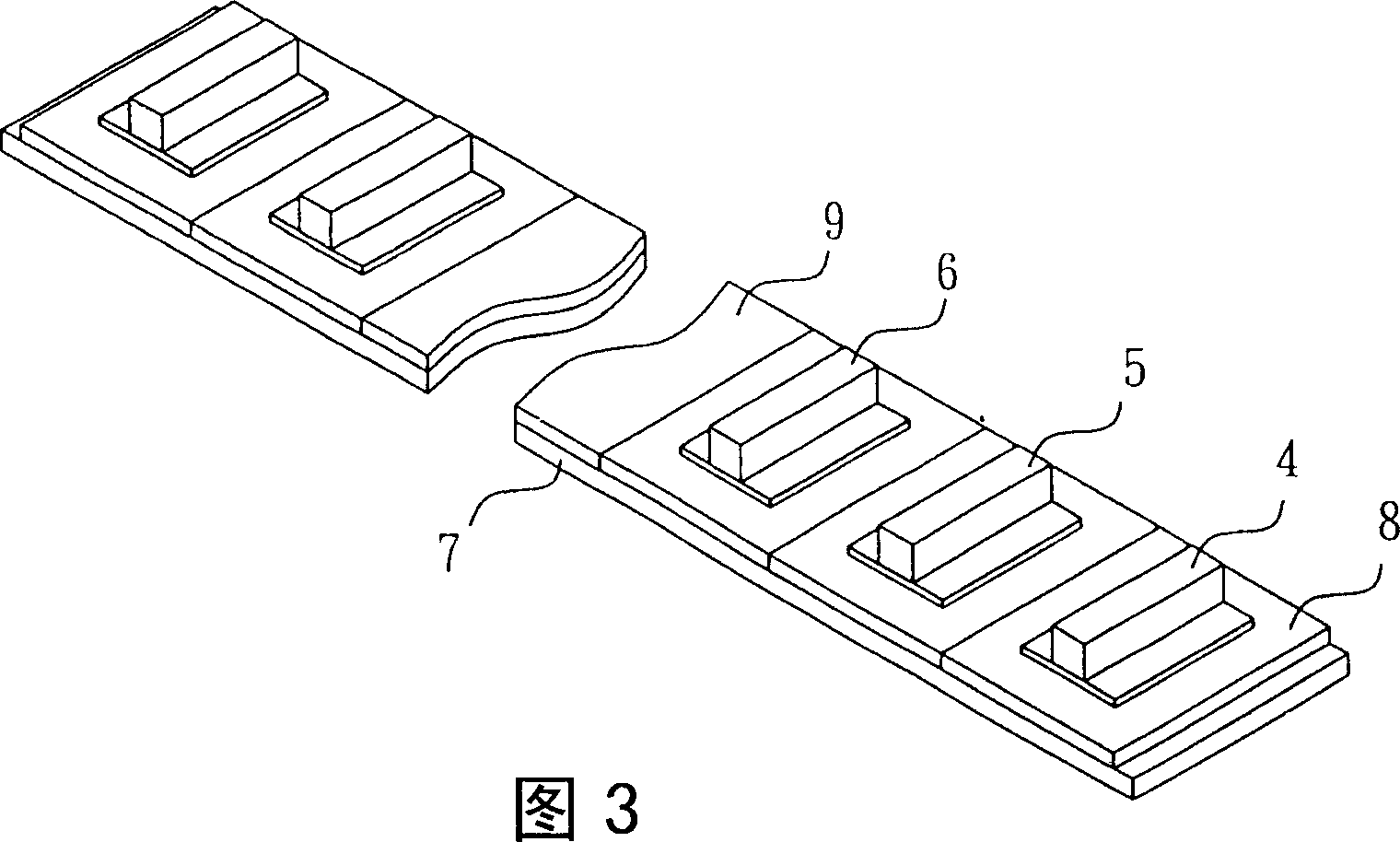

[0073] see Figure 7 , Figure 8 , Figure 9 , Figure 10 shown. The holders 50 and 50' of the first embodiment of the present invention respectively include a fixing groove 51 recessed below the body at the center of the body to accommodate a fixing rod 52; the sides of the body near the periphery have plural symmetry The accommodating grooves 53, 53', 53" are for accommodating the weight 54. The accommodating grooves 53, 53', 53" are respectively arc groove-shaped, round-shaped and long groove-shaped. The bodies of the holders 50, 50' are respectively circular and square. The body of the fixture 50 is combined with a plurality of clamps 500 . Each clamp 500 engages at least one fiber end face ferrule 55 to engage an optical fiber 56 to be polished. There is a grinding surface 57 below the ferrule 55 , and the grinding surface 57 is combined on the base 58 . The upper end of the fixing rod 52 is combined with a bracket 59 . The bottom of the fixing rod 52 has a socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com