Cation dye normal pressure deep dyeing estercopolymer and its preparing method

A cationic dye, atmospheric pressure deep dyeing technology, applied in the field of cationic dye atmospheric pressure deep dyeing copolyester and its preparation, can solve the problems of small dosage, inability to use as masterbatch, inconvenient industrial production, etc., and achieve anti-pilling The effects of improved performance, increased uniformity, and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

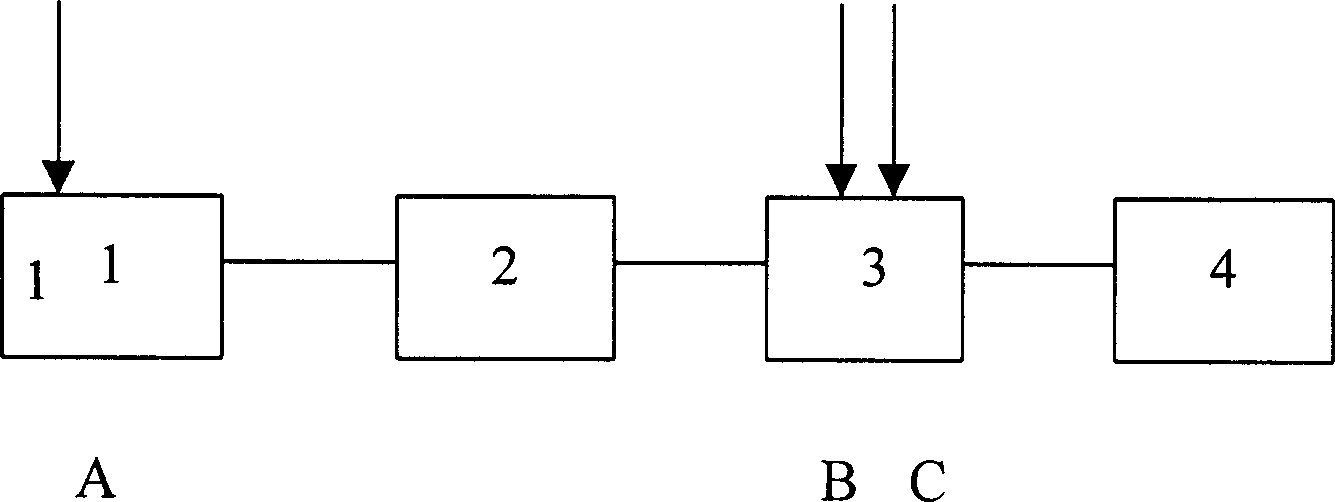

Image

Examples

Embodiment 1

[0022] It adopts semi-continuous polyester polymerization equipment with an annual output of 5000T. Put 95% PTA, 5% PIA, 1.23mol (relative to PTA) EG into the beating tank, add 3 / 10,000 catalyst (relative to PTA), and 1.5 / 10,000 stabilizer (relative to PTA). Continuously enter the esterification tank, and control the temperature of the esterification tank to be 250-260°C. After the esterification rate reaches 90%, it is introduced into the depolymerization kettle, the oligomer is depolymerized, and then the SIPM ethylene glycol solution equivalent to 5% by weight of PTA is added into the polycondensation kettle for polymerization reaction, and the temperature in the polycondensation kettle is controlled at 270- At 280°C, under the action of the EG steam jet pump, the vacuum degree is less than 50Pa, and the copolyester has an intrinsic viscosity of 0.600dl / g and a Tm of 250°C.

Embodiment 2

[0024] Using semi-continuous polyester polymerization equipment, put 95% PTA, 5% DDA, 1.23mol (relative to PTA) EG in the beating tank, add catalyst 3 / 10,000 (relative to PTA), stabilizer 1.5 / 10,000 (relative to PTA) PTA). Continuously enter the esterification tank, after esterification, add SIPM ethylene glycol solution equivalent to 7% by weight of PTA and introduce it into the polycondensation tank for polymerization reaction to obtain a copolyester with intrinsic viscosity of 0.550dl / g and Tm=245°C.

Embodiment 3

[0026] Using semi-continuous polyester polymerization equipment, put 95% PTA, 5% DDA, 1.23mol (relative to PTA) EG in the beating tank, add catalyst 3 / 10,000 (relative to PTA), stabilizer 1.5 / 10,000 (relative to PTA) PTA). Continuously enter the esterification tank, after esterification, add SIPM ethylene glycol solution equivalent to 10% by weight of PTA, and introduce it into the polycondensation tank for polymerization to obtain a copolyester with an intrinsic viscosity of 0.500 and a Tm of 220°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| T m | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com