Discharge lamp of the short arc type

A discharge lamp and short arc technology, applied in the direction of discharge lamps, gas discharge lamps, high pressure discharge lamps, etc., can solve the problems of high cost and easy disconnection, and achieve the effect of preventing falling off and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

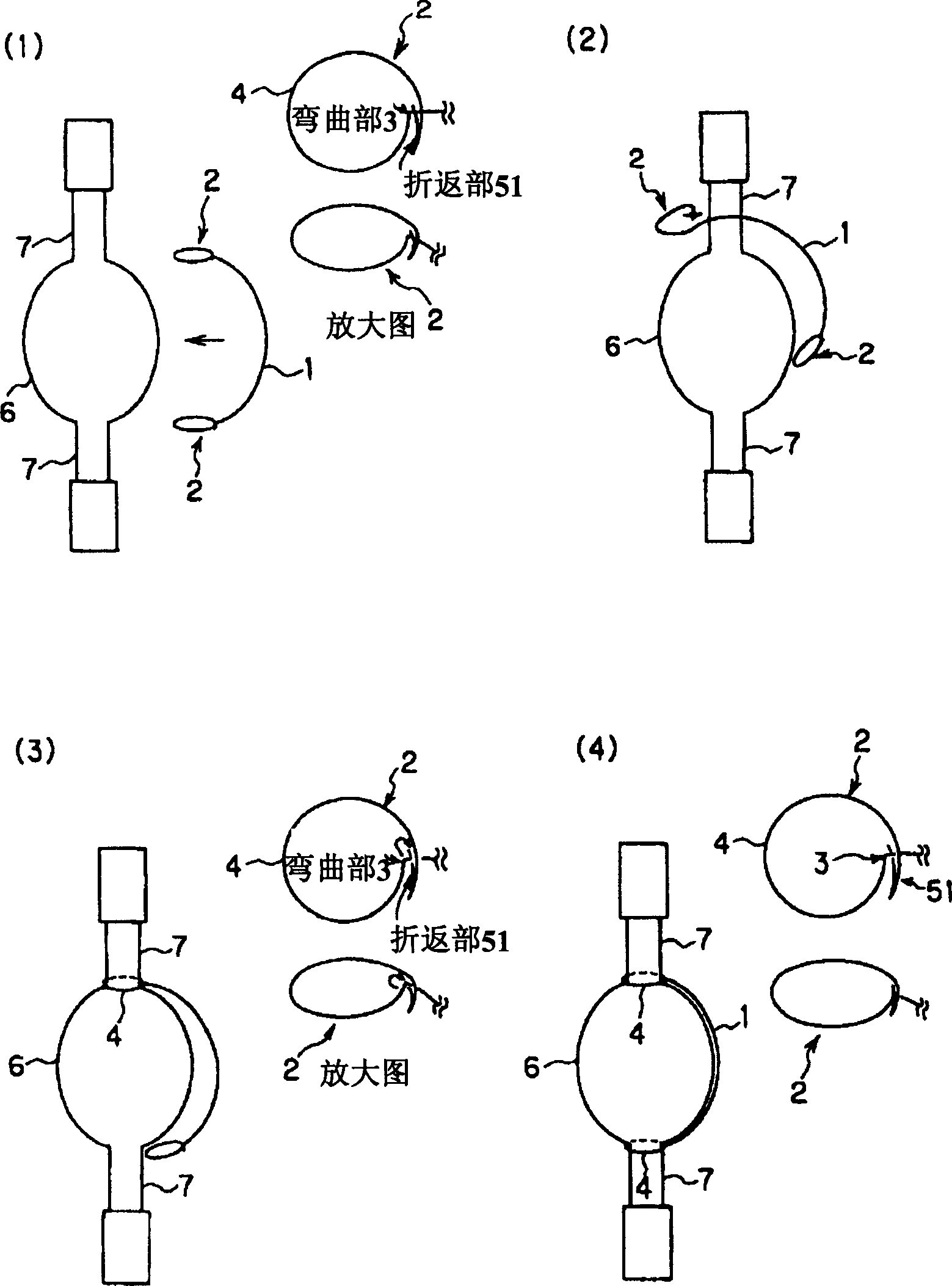

[0027] use Figure 1 to Figure 3 The first embodiment of the present invention will be described.

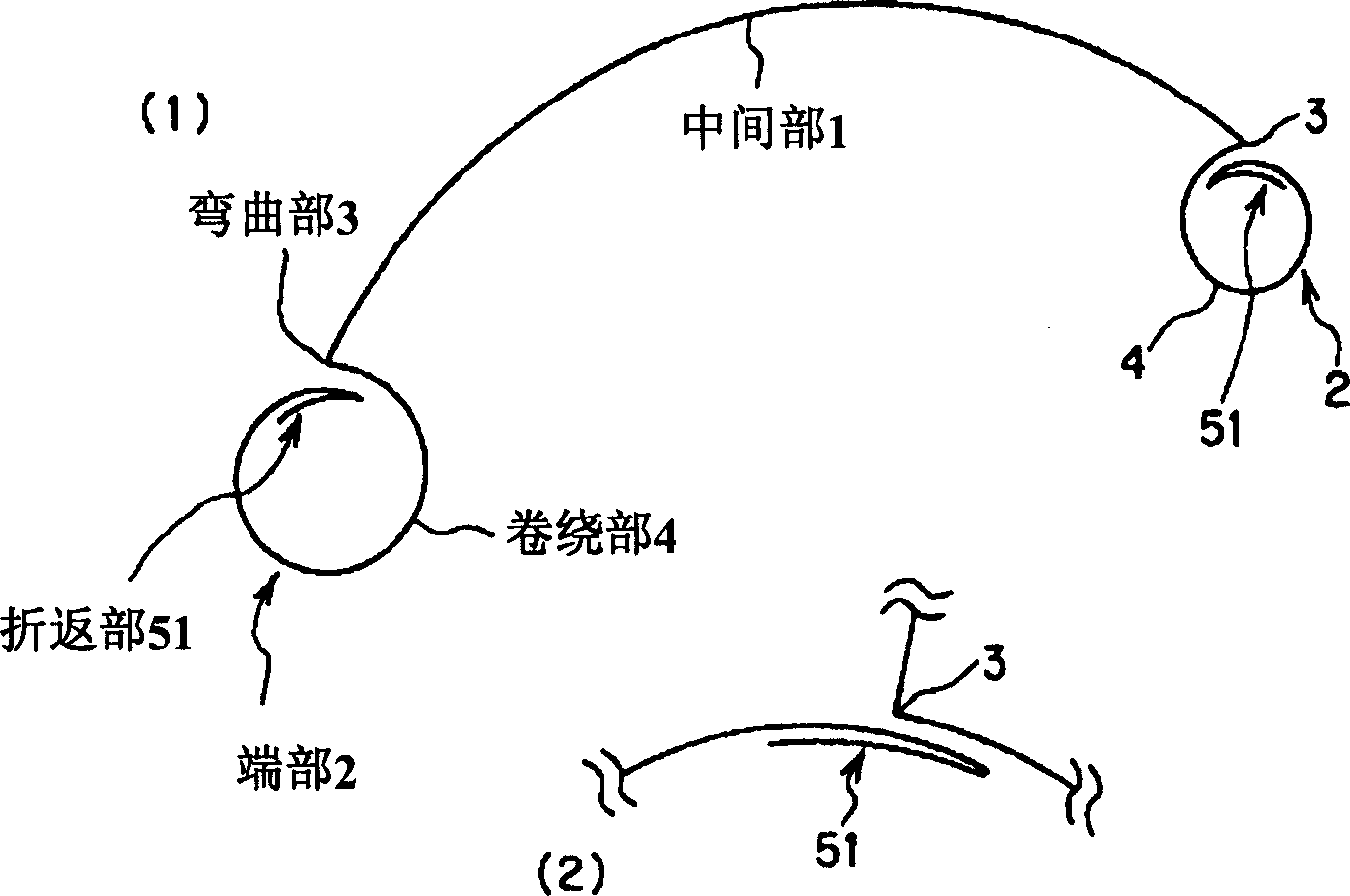

[0028] figure 1 (1) is a diagram showing the structure of the trigger wire fixed to the short-arc discharge lamp in the invention of the present embodiment, figure 1 (2) is figure 1 An enlarged view of the vicinity of the bent portion 3 and the folded portion 51 shown in (1).

[0029] In these figures, 1 is the middle part of the arc-shaped trigger wire arranged along the outer surface of the arc tube of the short-arc discharge lamp; 2 is the end of the trigger wire fixed to the sealing tube of the short-arc discharge lamp; 3 is a bent portion formed between the middle portion 1 and the end portion 2; 4 is a winding portion wound around the sealing pipe portion in the end portion 2; 51 is a folded back at the front end portion of the end portion 2 into a substantially V-shape department.

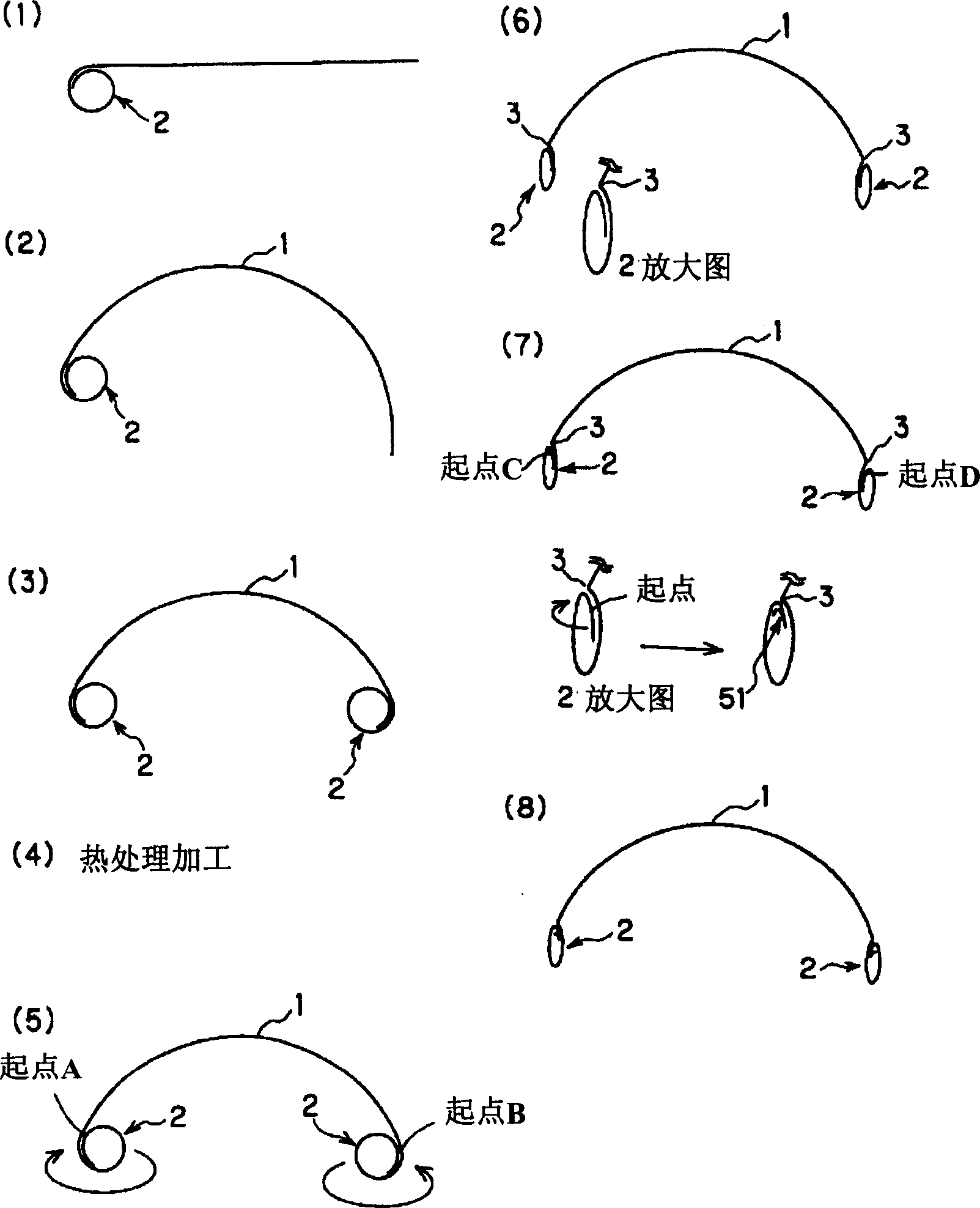

[0030] figure 2 yes means figure 1 (1) Fabrication process of the trigger wire sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com