Gear type machining tip and tool attaching the same thereon

A tip, workpiece technology, applied in stone processing tools, sawing machine tools, manufacturing tools, etc., can solve problems such as increased cutting load, shank bending, and excessive processing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are shown in the accompanying drawings.

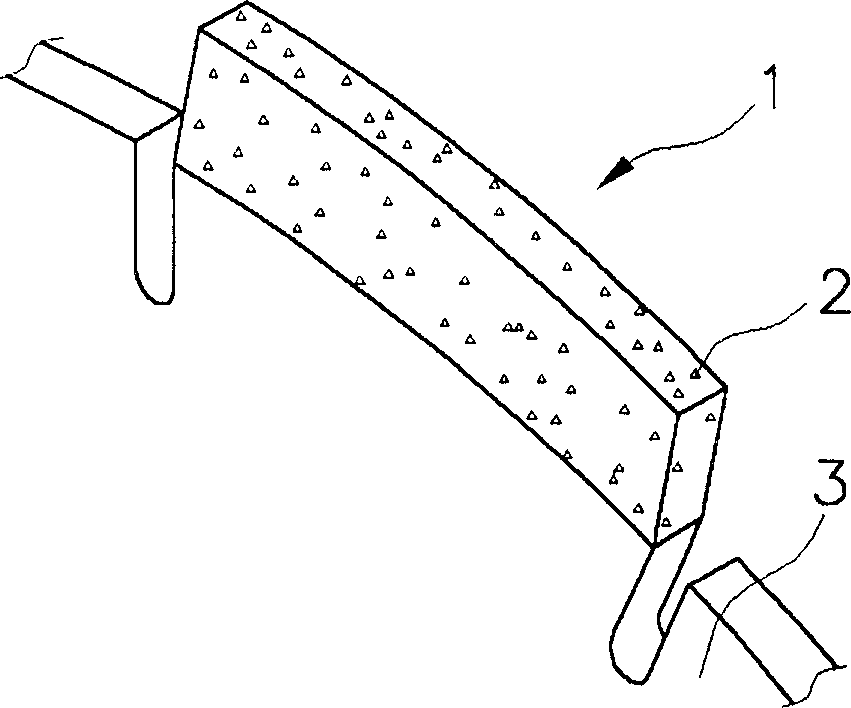

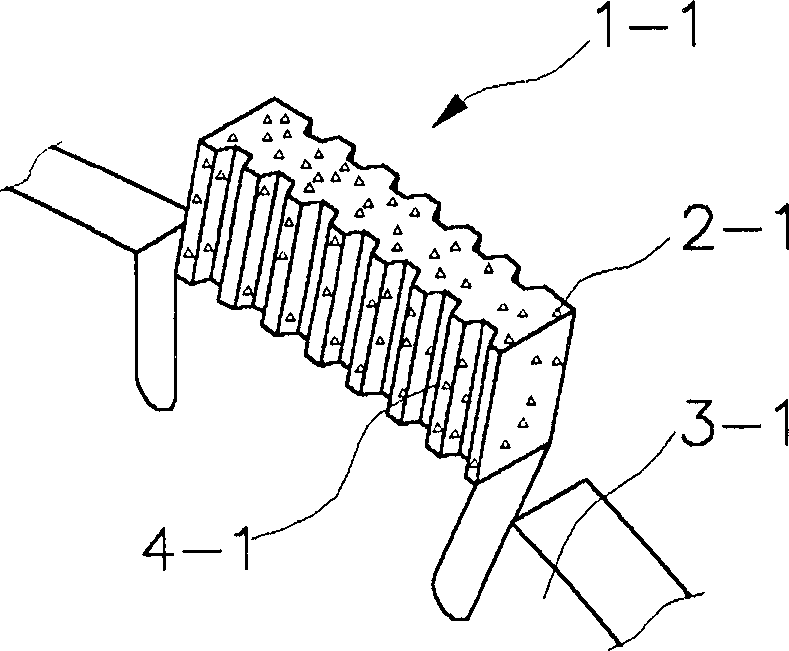

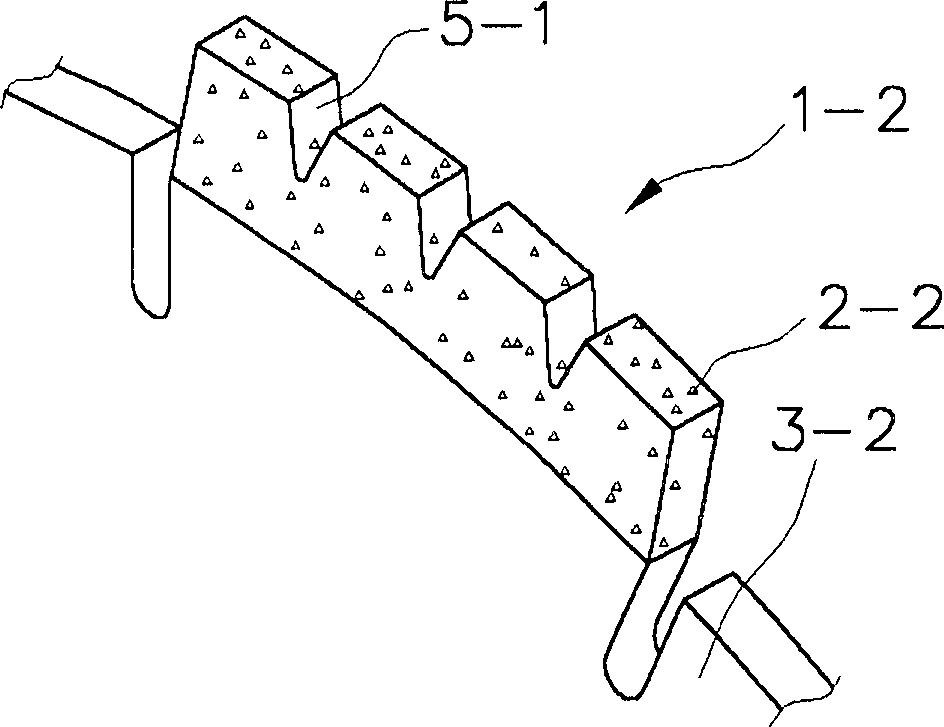

[0071] The sawtooth-shaped cutting tip of the present invention having a double-layer structure includes: an adhesive layer containing super wear-resistant particles therein and having grooves formed on the working surface in contact with the workpiece; and a spacer layer with For attaching the adhesive layer to the handle. The zigzag cutting tip of the present invention is divided into a segmented cutting tip and a continuous rim cutting tip. In addition, the cutting tip of the present invention is mounted on the outer periphery of the cutting tool of the present invention, which is classified into a cutting tool, a grinding tool, and a drilling tool according to functions. A preferred embodiment of the invention will be described below with reference to a segmented cutting tip, but this is done by way of example only.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com