Nanometer composite acrylic resin with high solid content and low viscosity and the prepn of its coating

A composite acrylic, high-solid and low-viscosity technology, applied in the direction of coating, etc., can solve the problems of reducing the transparency of the coating, increasing the viscosity of the resin, and making it difficult to improve the performance of the coating more effectively, so as to improve the hardness and weather resistance, and improve the performance , The effect of improving wear resistance and scratch resistance

Active Publication Date: 2006-03-01

FUDAN UNIV

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Even after the surface modification of nano-oxide powder particles, it is difficult to completely and evenly disperse into the resin, so it is difficult to improve the performance of the coating more effectively, and even cause the viscosity of the resin to increase and reduce the transparency of the coating.

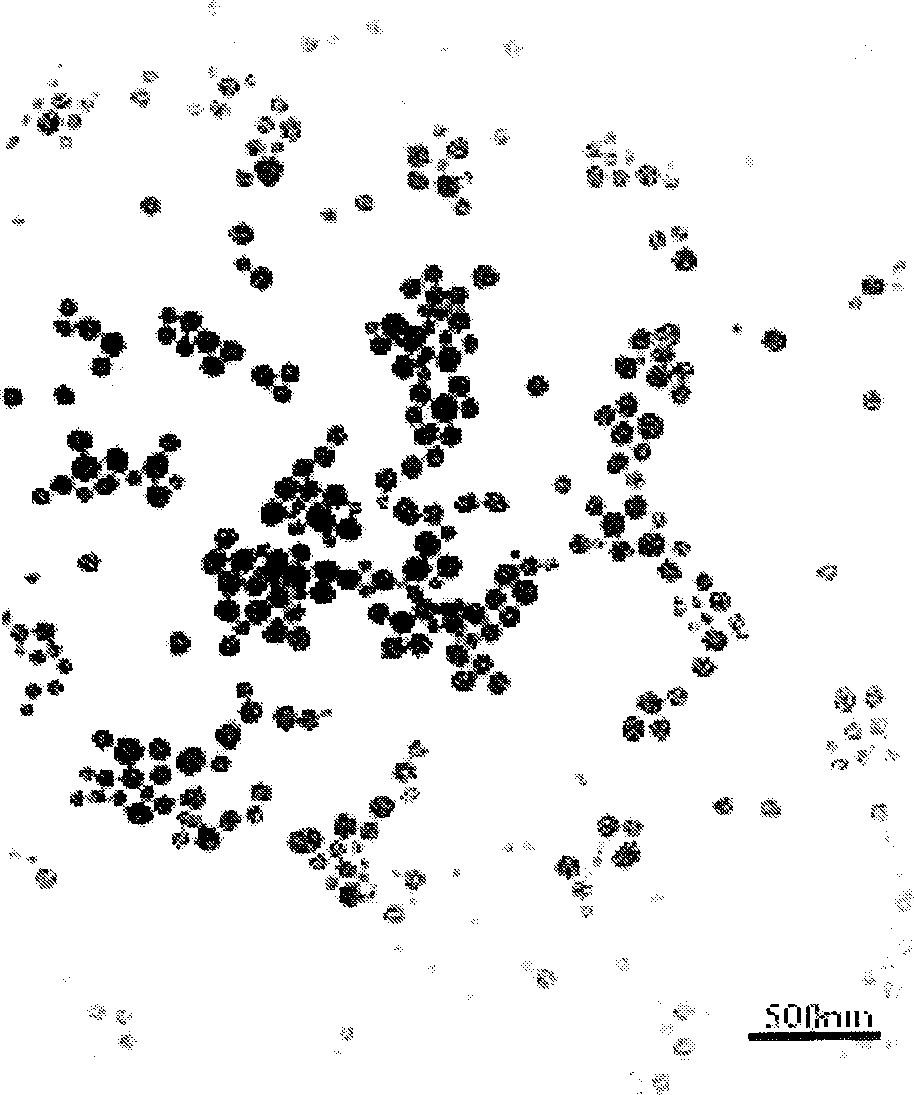

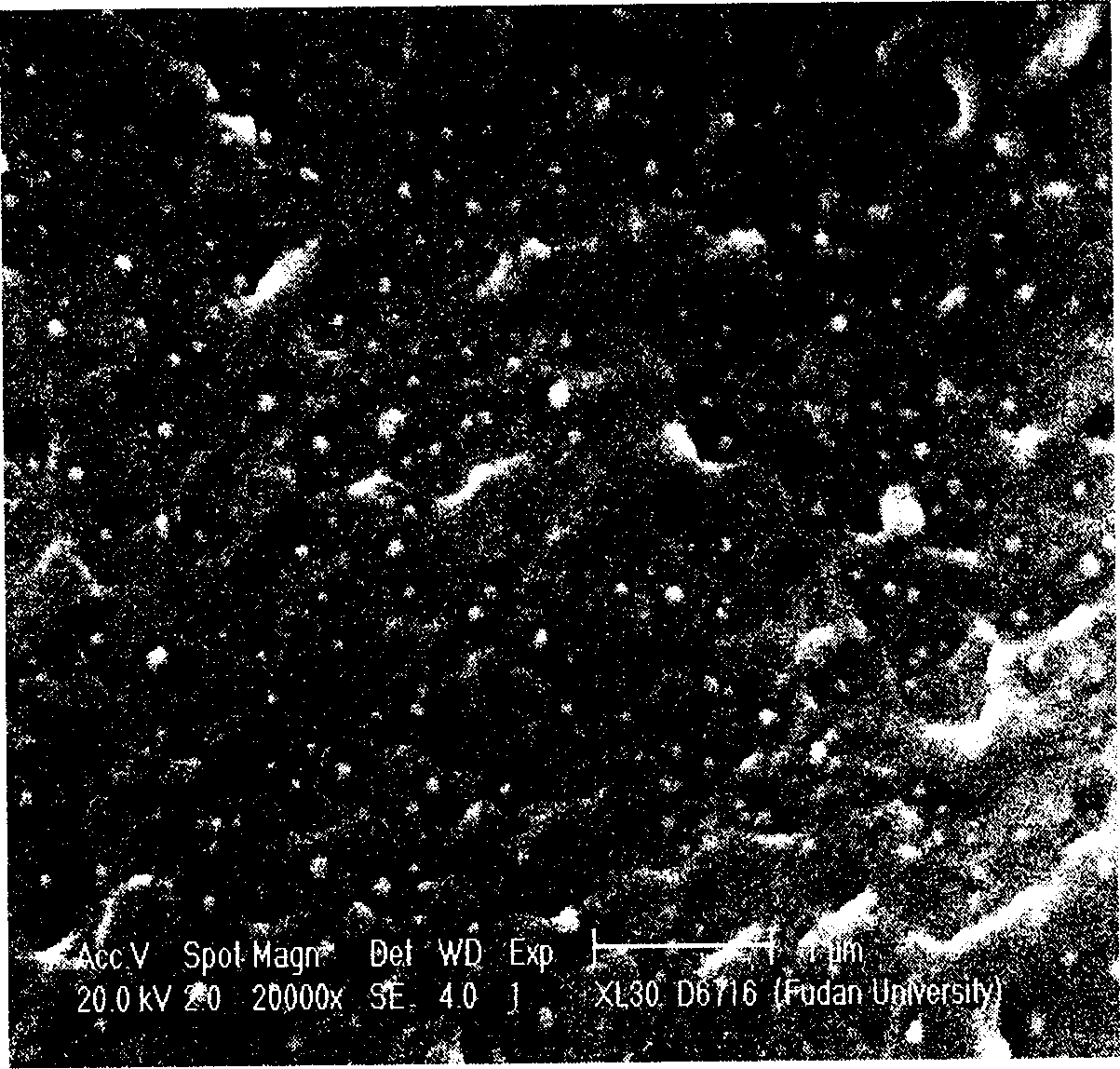

The nano-oxide sol is easy to modify the surface, easy to uniformly disperse in the acrylic resin and its coating, and forms a strong interaction with the polymer molecules, which can not only significantly improve the performance of the coating, but also maintain the transparency of the coating However, nano-oxide sols usually use alcohol or water as the dispersion medium (alcohol sol or water sol), and it is difficult to directly introduce them into solvent-based acrylic resins and their coatings.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] example

[0036] example

Embodiment 2

[0039] Resin viscosity (mPa.s)

[0040] example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention belongs to the field of new chemical material, and is one kind of nanometer composite acrylic resin with high solid content and low viscosity and the preparation of its coating. The nanometer composite acrylic resin is prepared with nanometer oxide sol and acrolactic ester monomer or acrolactic ester resin, and through mixing, decompression distillation to eliminate alcohol or water, and in-situ polymerization or mixing. It has solid content higher than 70 wt%, viscosity lower than 2500 mPa.s, and content of nanometer oxide dispersed homogeneously in the resin system in 1-30 wt%. The nanometer composite acrylic resin may be cross-linked and cured together with isocyanate or amino resin to obtain nanometer composite acrylic resin coating, and the coating has high transparency and glossiness, high antiwear performance, high scratch resistance, high hardness, high weather resistance, etc. and may be used for automobile, plastic, metal, etc.

Description

technical field [0001] The invention relates to the field of new chemical materials, and relates to a preparation method of a high-solid and low-viscosity nano-composite acrylic resin and a coating thereof. Background technique [0002] Acrylate resin coatings are widely used as automotive coatings, coil coatings, plastic coatings, metal coatings due to their high transparency, high gloss, high toughness, excellent weather resistance, solvent resistance and gloss retention, etc. etc., but the conventional acrylic coating has low solid content and pollutes the environment to a certain extent, and its wear resistance, scratch resistance, hardness, and weather resistance still need to be improved. [0003] Chinese patent ZL02111699.7 reports a preparation method of a high-scratch-resistant nano-composite polyurethane coating. Nano-composite acrylate polyurethane coatings are obtained by modifying nanoparticles such as nano-silica and calcium carbonate in situ or by blending. ,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L33/08C08F2/44C08F220/10C09D133/08

Inventor 武利民陈国栋游波周树学

Owner FUDAN UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com