Bischofite dehydration-electrolysis method for refining magnesian

A bischofite and anhydrous magnesium chloride technology, applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of large amount of electrolytic furnace slag, decreased current efficiency, and electrolyte consumption, and achieve high conductivity, reduced impact, and reduced recycling costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

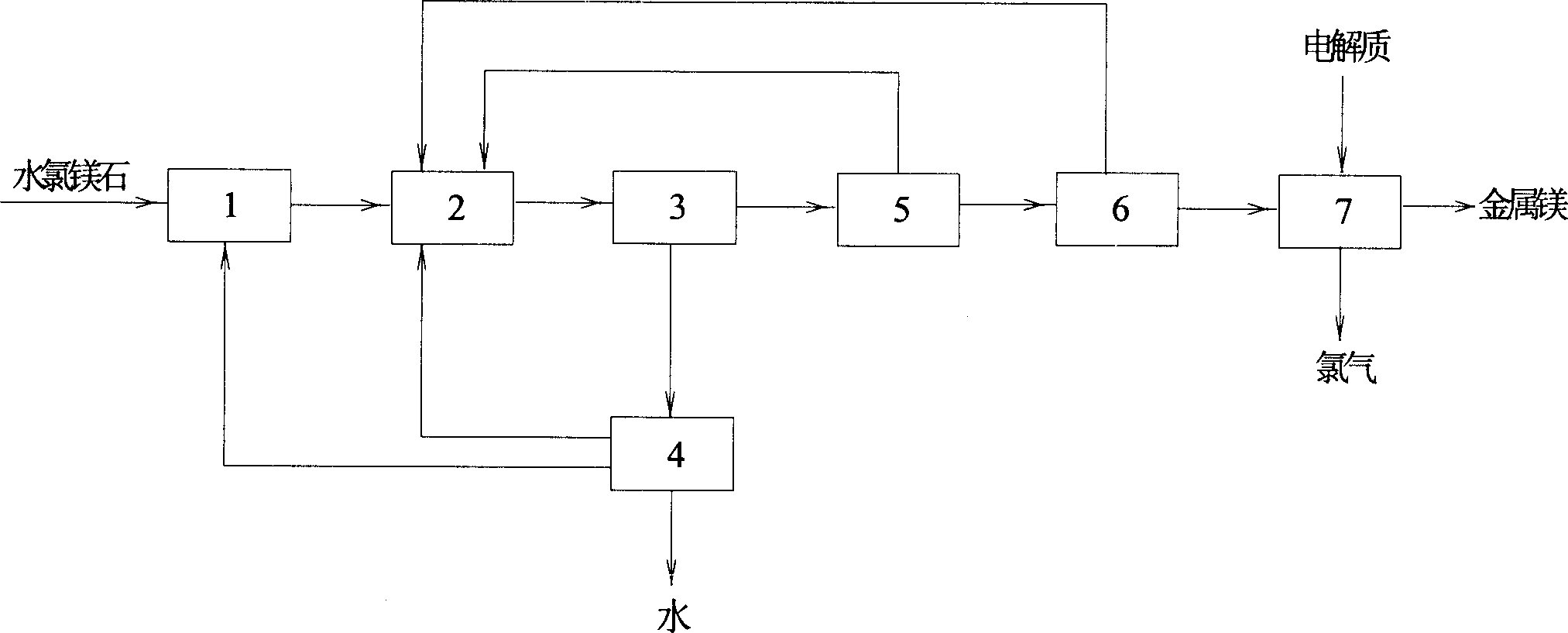

Image

Examples

preparation example Construction

[0028] (2) Preparation of electrolytic magnesium smelting electrolyte;

[0029] Its main components are still: NaCl-KCl-MgCl 2 -CaCl 2 , adding fluoride (such as MgF 2 , LiF, NaF, CaF 2 etc.) and containing rare earth chlorides (such as NdCl 3 、LaCl 3 etc.), effectively increasing the solubility of MgO in complex electrolyte systems. Wherein the weight percent scope of each component of electrolytic solution is:

[0030] NaCl: 20-40, KCl: 10-30, MgCl 2 : 7~15, CaCl 2 : 20-30, fluoride: 2~6, rare earth chloride: 3~5.

[0031] Wherein the fluoride is selected from MgF 2 , LiF, NaF, CaF 2 One or several mixtures.

[0032] Wherein the rare earth chloride is selected from NdCl 3 、LaCl 3 One or several mixtures.

[0033] Physical and chemical indicators of the new electrolyte: electrical conductivity: 2.2-2.87 ohm-1.cm-1, surface tension: 0.09-0.14N / m, density: 1.5-1.67g / cm3, primary crystal temperature: 550-652°C.

[0034] (3) Coupling reaction crystallization to pre...

Embodiment 1

[0050] In a 5-liter reactor, add 3,500 grams of magnesium chloride organic solution prepared at a rate of 3 liters / hour, containing 10% magnesium chloride, 11.7% water, 1.0% ammonium chloride, 45% methanol, and ethylene dichloride. Alcohol 32.7%; under the condition of normal temperature and stirring, the precipitant ammonia gas is introduced at a rate of 0.8m3 / h. After the feeding is completed, continue to stir and mature and recrystallize for 1 hour, filter the slurry-like feed liquid, and saturate it with ammonia Washed with a mixture of 100 grams of methanol and 20 grams of ethanol, the solid product was dried at 120°C for 1.2 hours with isolated air, and melted and deaminated at 760°C for 1.2 hours. Anhydrous magnesium chloride, the molten anhydrous magnesium chloride can be used for electrolysis. The content is less than 0.3%, the magnesium oxide content is 1.4%, and the productive rate of magnesium chloride is 89.3%.

[0051] Add 2000 grams of electrolyte in the electro...

Embodiment 2

[0053] The preparation method of anhydrous magnesium chloride is with embodiment 1.

[0054] Add 2500 grams of electrolyte to the electrolyzer in the tank without separator, its composition NaCl: 45%, KCl: 10%, MgCl 2 : 12%, CaCl 2 : 25%, MgF 2 : 3%, CaF 2 : 2%, NdCl 3 : 3%,. The conductivity of the electrolyte: 3.02S / m, the solubility of MgO in the electrolyte is 1.70g / 100g, the electrolysis voltage is 4.9V, the electrolysis current is 40 amperes, and the pole distance is 8cm. Current efficiency: 91.2%, power consumption: 12.1kWh / Kg-Mg, purity of magnesium: 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com