Complete paper package box with relief surface and its production process

A production process and packaging box technology, applied in embossed decorative parts, packaging, wrapping paper, etc., can solve the problems of lack of three-dimensional effect, appearance design, single internal structure and high cost, and achieve the effect of novel production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

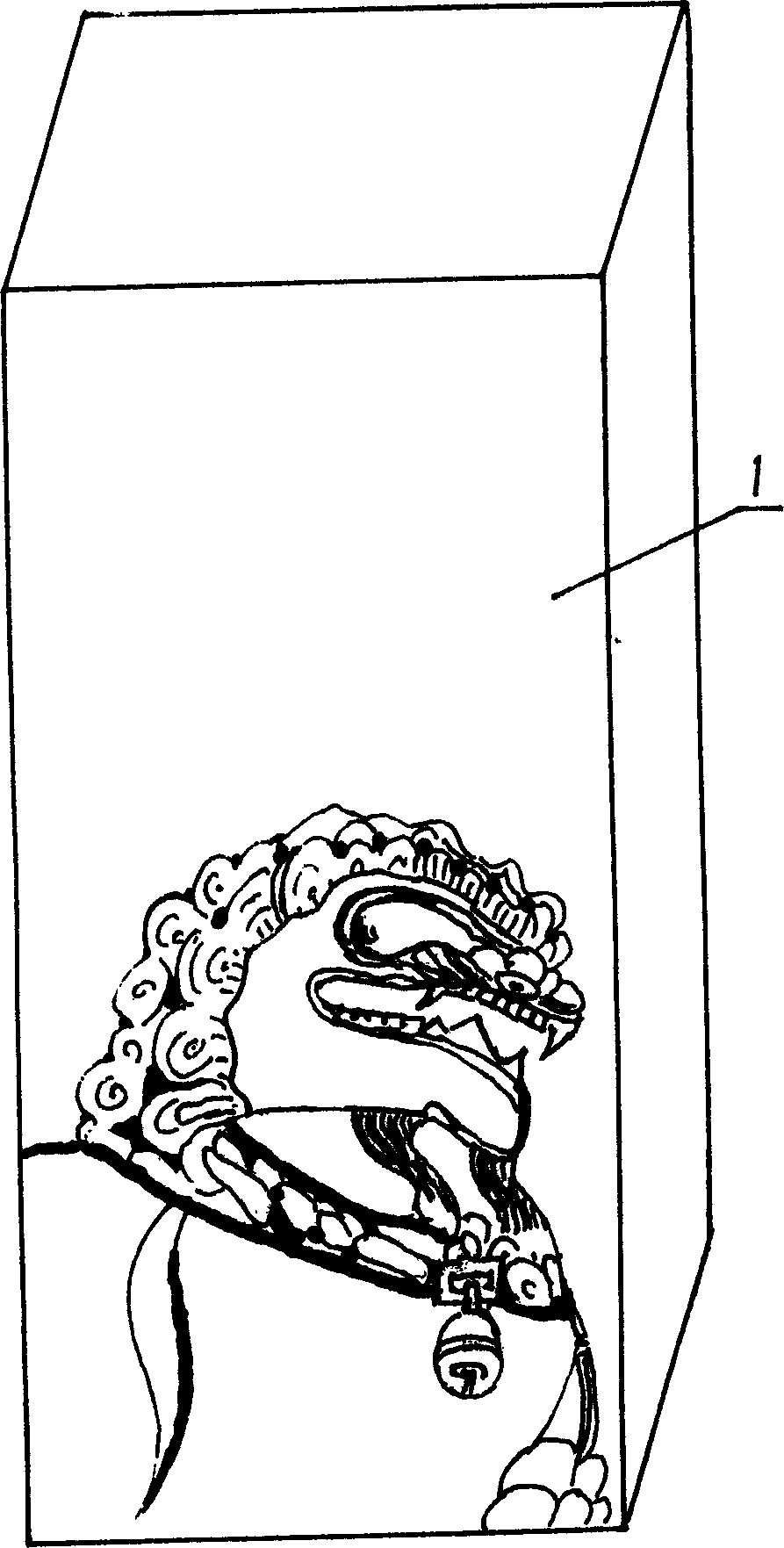

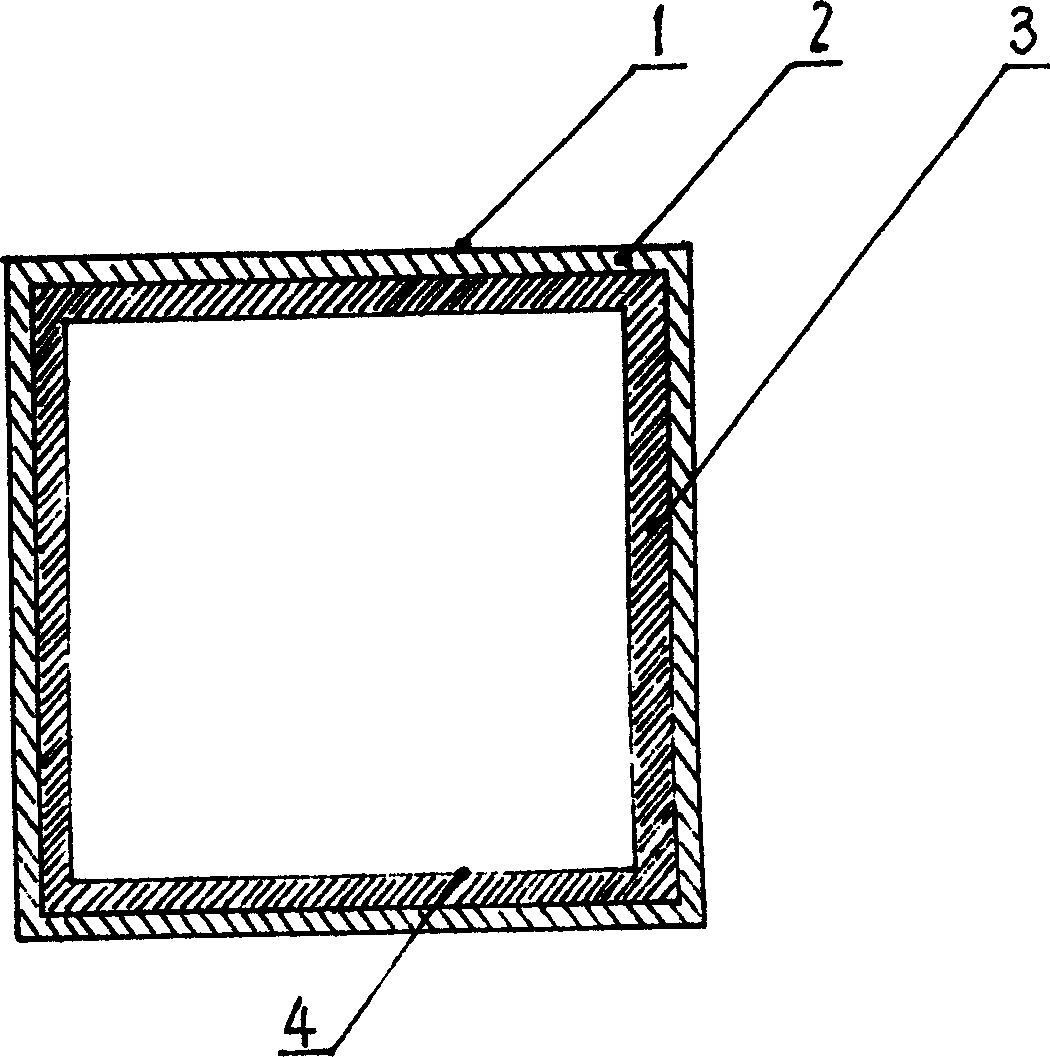

[0023] refer to figure 1 , figure 2 , at least one surface of the packaging box with a paper composite layered structure has an embossed finish 1, and its layered structure is composed of a face paper layer 1 with an embossed face (face paper is also called special paper, and special paper is specially referred to in this industry. Silk paper or hot-melt paper, etc.), the cardboard layer 2, the cardboard layer 3 and the inner paper layer 4 are bonded together to form a whole. The embossed veneer is to mechanically extrude the packaging box with a composite layer structure on the required box surface with a target mold to have a concave-convex image. In addition to the images shown in the accompanying drawings, other different images (such as animals and plants, landscapes, portraits of people, etc.) can also be implemented. The embossed finish of the packaging box with embossed finish is one of rectangular, round or oval, shaped. Packages with an embossed finish The emboss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com