Colorful yarn and its blow spinning method

A color segment yarn and color technology, which is applied in yarn, spinning machine, textile and paper making, etc., can solve the problems of expensive price and difficulty in popularization and application, and achieve good appearance and hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1 cotton / viscose / color polyester

[0011] Natural fiber: cotton / viscose, colored fiber: colored polyester, natural color:color=90:10. Color section yarn specification: 12s / 1.

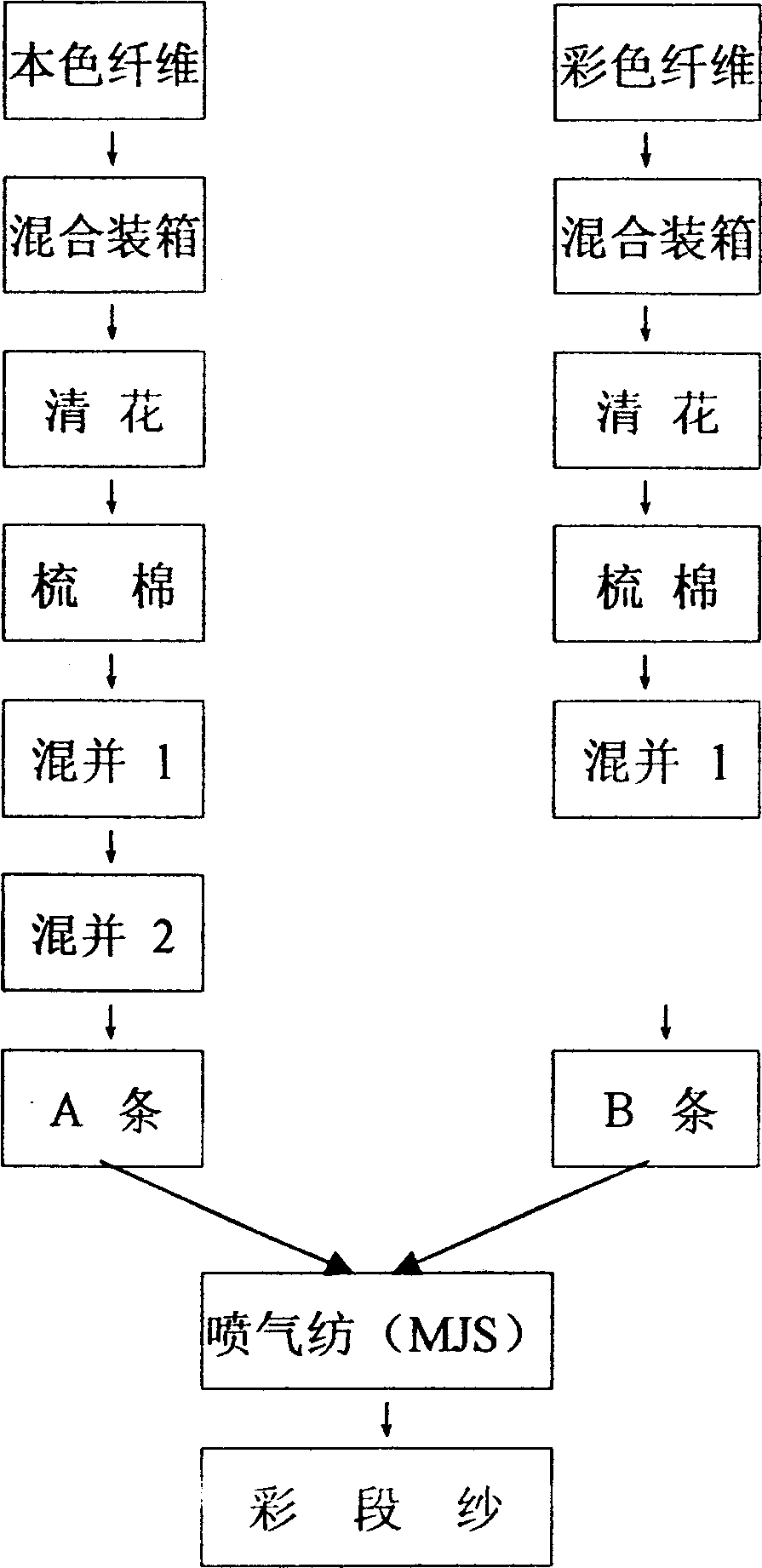

[0012] Routing:

[0013] Natural fiber-cotton 70% / viscose 30%-mixed phase-cleaning-carding-parallel 1-parallel 2—A strip, the quantitative control of A strip is about 3g / m. Colored fiber-colored polyester-mixed phase according to color ratio-clearing-carding-and 1——B strip, the quantitative control of B strip is about 2g / m2. Strip A and strip B are combined into strips according to the weight ratio of 90 / 10-MJS (air-jet spinning)-spun into 12s / 1 color segment air-jet yarn.

Embodiment 2

[0014] Embodiment 2 cotton / spun silk / color viscose

[0015] Natural fiber: cotton / spun silk, colored fiber: colored viscose, natural color:color=80:20.

[0016] Color section yarn specification: 21s / 1.

[0017] Routing:

[0018] Natural fiber-cotton 80% / spun silk 20%-mixed phase-cleaning-carding-parallel 1-parallel 2—A strip, the quantitative control of A strip is about 4g / m. Colored fiber-colored viscose-mixed phase according to color ratio-clearing-carding-and 1——B strip, the quantitative control of B strip is about 3g / m. Strip A and strip B are combined into strips according to the weight ratio of 80 / 20—MJS—spun into 21s / 1 color segment air-jet yarn.

Embodiment 3

[0019] Embodiment 3 cotton / ramie / dyed cotton fiber

[0020] Natural fiber: cotton / ramie, colored fiber: dyed cotton fiber, natural color:color=80:20.

[0021] Color section yarn specification: 30s / 1.

[0022] Routing:

[0023] Natural fiber-cotton 80% / ramie 20%-mixed phase-cleaning-carding-parallel 1-parallel 2—A strip, the quantitative control of A strip is about 3.5g / m. Colored fiber-dyed cotton fiber-mixed according to color ratio-packing-blowing-carding-and 1——B strip, the quantitative control of B strip is about 2g / m2. Strip A and strip B are combined into strips according to the weight ratio of 80 / 20-MJS——spun into 30s / 1 color segment air-jet yarn

[0024] The second category: Natural fiber (represented by item A, the same below) is made of viscose (including various cellulose fibers such as tencel and modal) and mixed with silk and hemp; colored fiber (represented by item B, the same below) ) is composed of colored polyester, colored viscose, and dyed cotton fibers....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com