Circular corridor for spinning of urethane elastic fiber

A spinning shaft and spandex technology, which is applied in the field of spinning shafts and circular spandex spinning shafts, can solve the problems of yarn bundle cross-section, turbulent hot air flow, large temperature difference, etc. performance, improve production efficiency, and avoid the effect of being blown flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

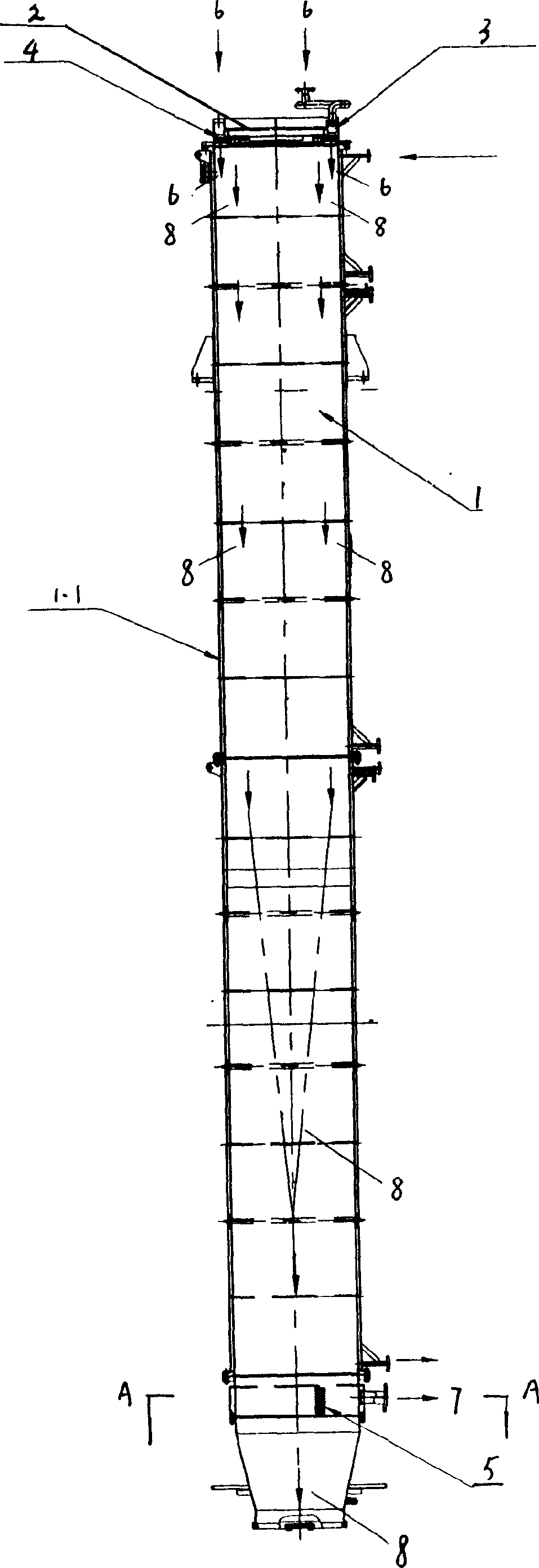

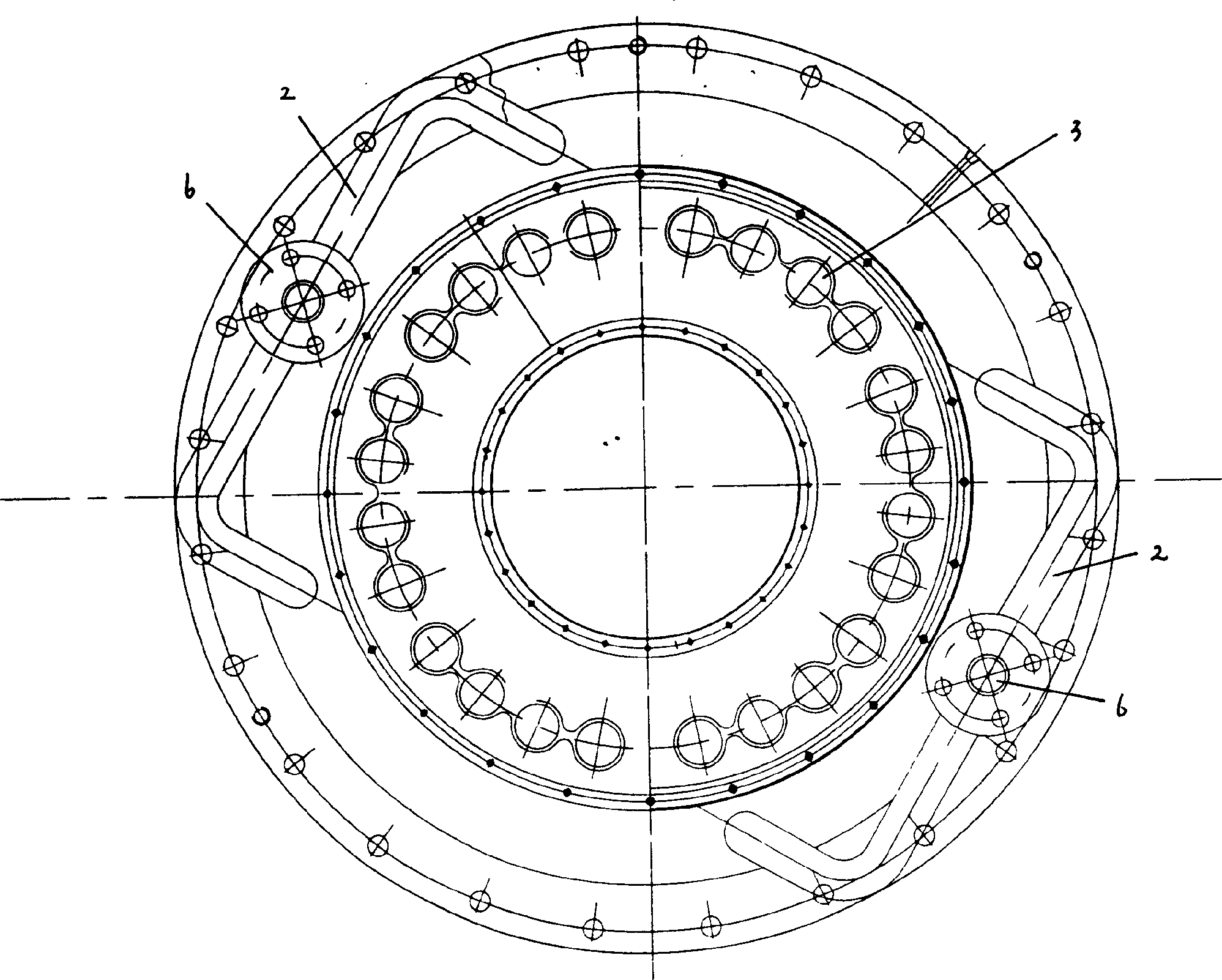

[0011] see Figure 1~2 , The invention is a circular spandex spinning tunnel. It is mainly composed of cylindrical tunnel body 1, spinneret assembly 2, annular blower 3, annular air inlet rectifier 4, annular return air rectifier 5, hot air inlet 6 and hot air outlet 7, etc. The spinneret assembly 2 is arranged in the middle of the top of the cylindrical tunnel body 1, the annular blower 3 is arranged on the periphery of the spinneret assembly 2 at the top of the cylindrical tunnel body 1, and the annular air inlet rectifier 4 is placed under the annular blower 3 , the annular return air rectifier 5 is arranged at the bottom of the cylindrical shaft body 1, the hot air inlet 6 is arranged at the top of the annular blower 3, and the hot air outlet 7 is arranged outside the annular return air rectifier 5. The outer wall of the cylindrical tunnel body 1 is covered with a heat tracing spacer 1.1 as a whole. 8 is spandex thread among the figure.

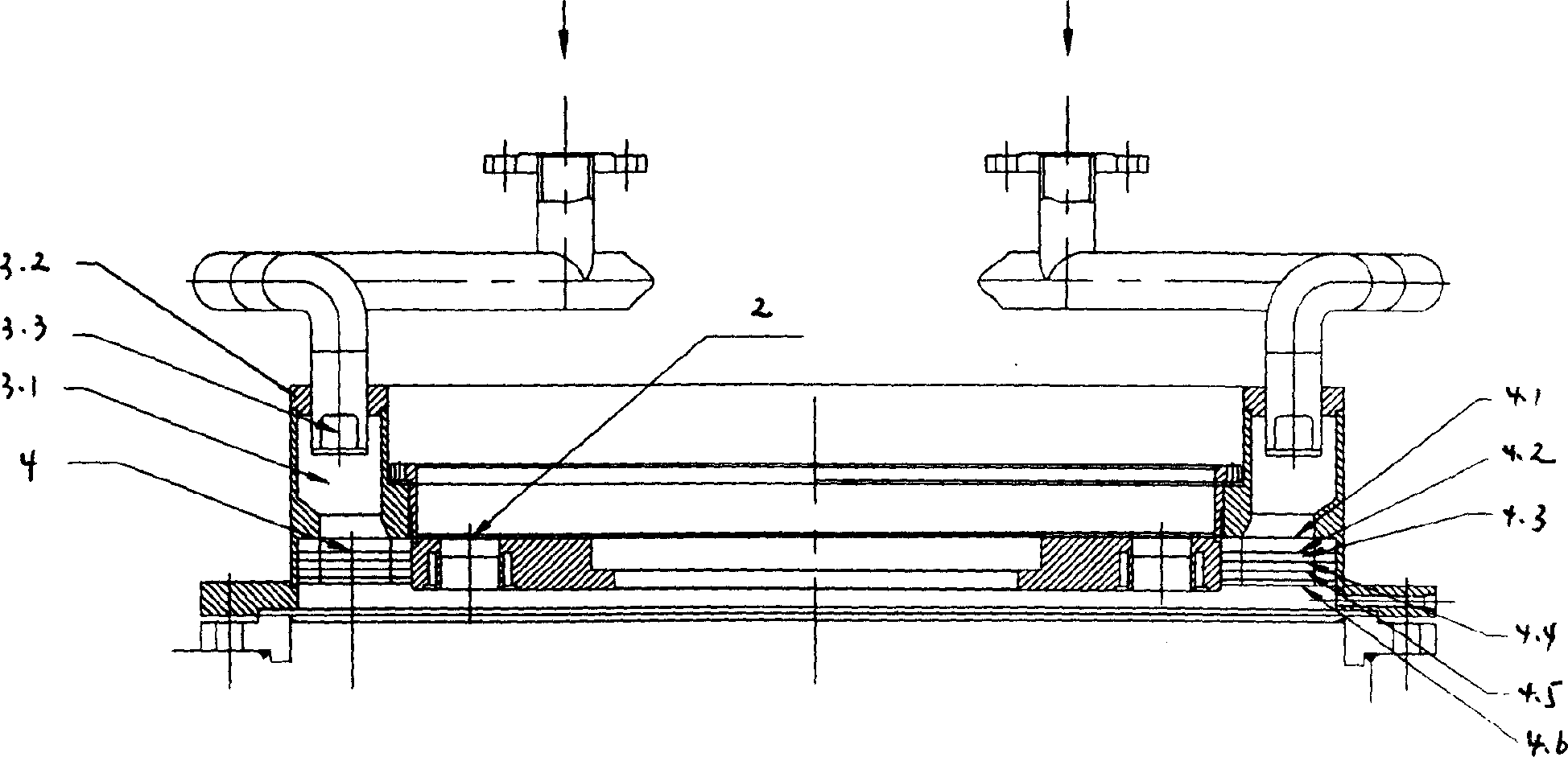

[0012] see image 3 , the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com