Longitudinal bamboo glue board and fabricating method

A technology of bamboo plywood and manufacturing method, which is applied in the direction of manufacturing tools, wooden veneer joints, wood processing appliances, etc., can solve the problems of inconsistent expansion and contraction of bamboo board fibers, reduced bamboo utilization rate, poor impact resistance, etc., and achieve good Physical stability, good impact resistance, strong moisture resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

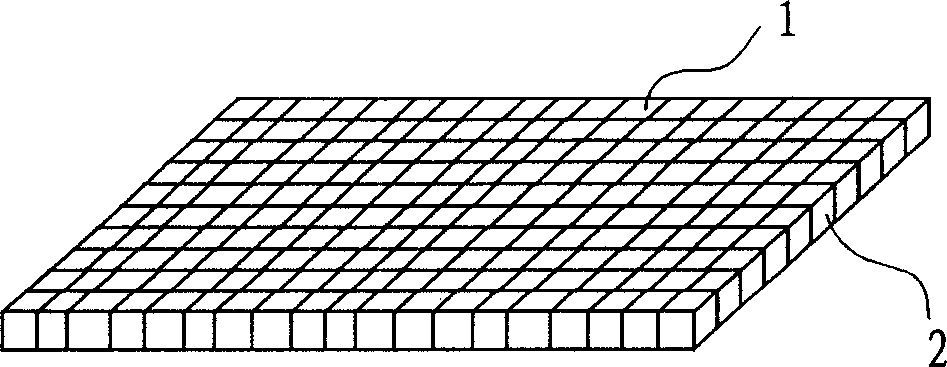

[0011] refer to figure 1 Shown, a kind of vertical face bamboo plywood, the upper surface 1 of plywood is the cross section of bamboo chip, is bonded by bamboo chip vertical section 2 between bamboo chip, and the upper and lower surfaces of bamboo chip form bamboo plywood.

[0012] Figure 2 to Figure 6 It is a structural schematic diagram of the manufacturing method of bamboo plywood, including in turn:

[0013] (1) figure 2 It is made of adult bamboo and sawn into a certain length of bamboo tube;

[0014] (2) image 3 It is processed bamboo slices; the process is: sawing into bamboo slices of a certain width with a blade saw; planing off bamboo green and bamboo yellow through a rough planer to ensure that the thickness is at a certain height; under the condition of maintaining freshness, use 5% The hydrogen peroxide is degreased and bleached in hot water at 95°C, and dried in a drying oven to keep the moisture content below 8%; it is fed into a rough planer to unify the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com