Uv light irradiating device

A technology of irradiating device and ultraviolet light, applied in lighting device, lighting device parts, optics and other directions, can solve the problem of resin ultraviolet degradation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

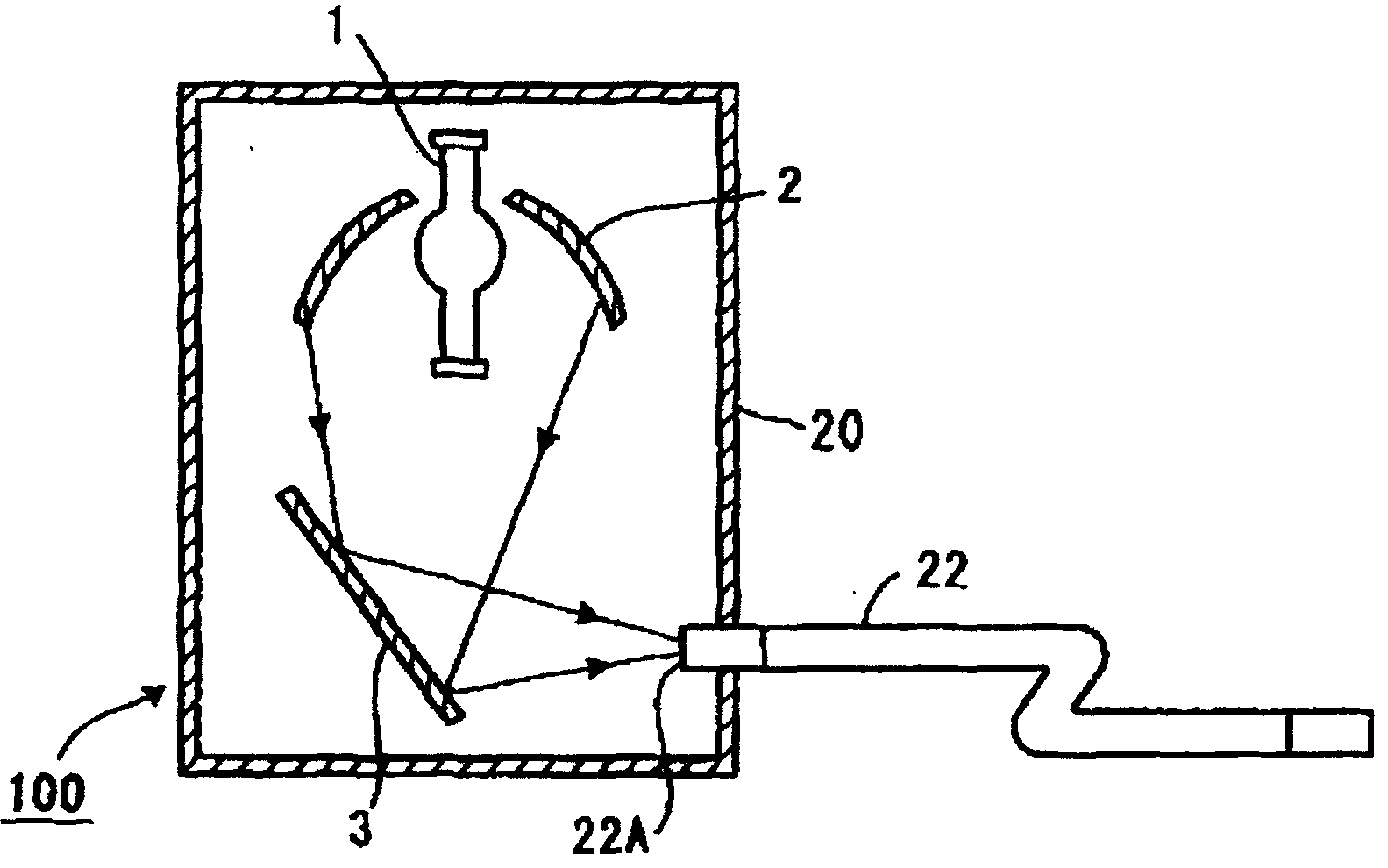

[0026] figure 1 An ultraviolet irradiation device 100 according to a typical embodiment of the present invention is shown. In the lamp body 20, the ultraviolet irradiation device 100 consists of a high-pressure mercury lamp 1, an elliptical reflector 2 that condenses the emitted light from the discharge lamp, and a plane reflector 3 that reflects the condensed light from the elliptical reflector 2 and guides it to an optical waveguide 22. constitute. The elliptical mirror is made of glass, and its reflective surface is coated with multi-layer evaporated film. The characteristic of the multilayer vapor-deposited film is to reflect ultraviolet light and transmit light from the visible light region to the infrared light region. A high-pressure mercury lamp 1 as a light source is schematically shown in figure 2 Among them, it is made of quartz glass, and consists of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com