Safety embedding in wall construction method of indoor fuel gas pipeline and accessory

A construction method and technology for gas pipelines, which are used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as inconvenient installation, poor corrosion resistance and unsightly appearance of valves and pipes in front of easy-to-modify stoves. To achieve the effect of eliminating gas leakage, good pressure resistance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

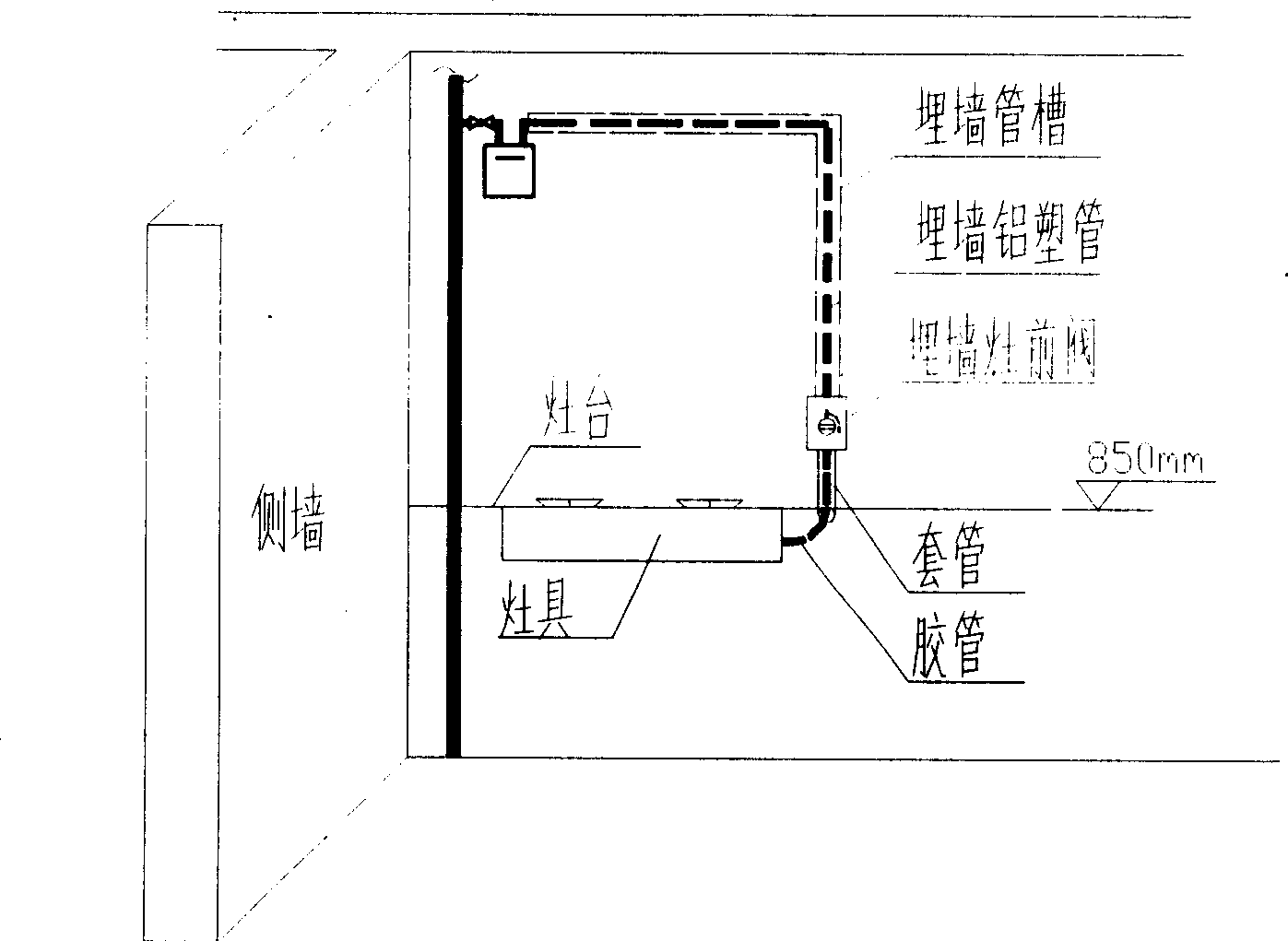

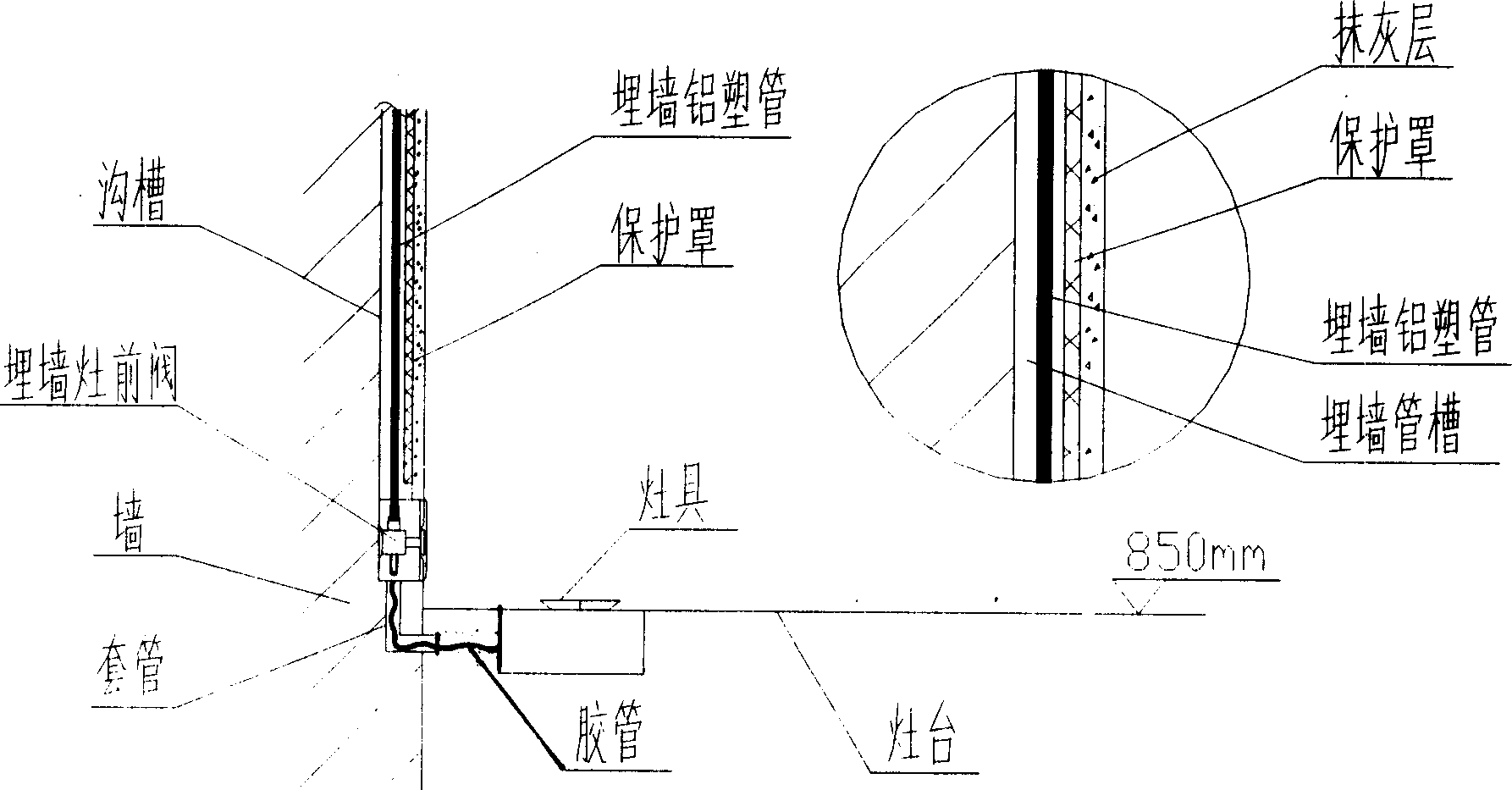

[0024] 1. Make a groove on the wall where the gas pipeline passes behind the gas meter. The groove should meet the requirements of 2.2.19 in the "Code for Construction and Acceptance of Urban Gas Indoor Engineering" CJJ94-2003, and the width is the outer diameter of the pipeline plus 20 mm;

[0025] 2. Lay the gas pipeline in the groove, and the gas pipeline adopts PE aluminum-plastic composite pipe. A trough-type hot-dip galvanized sheet protection cover is installed, and the enclosed space of the aluminum-plastic pipe inside the cover is filled with refractory materials without gaps.

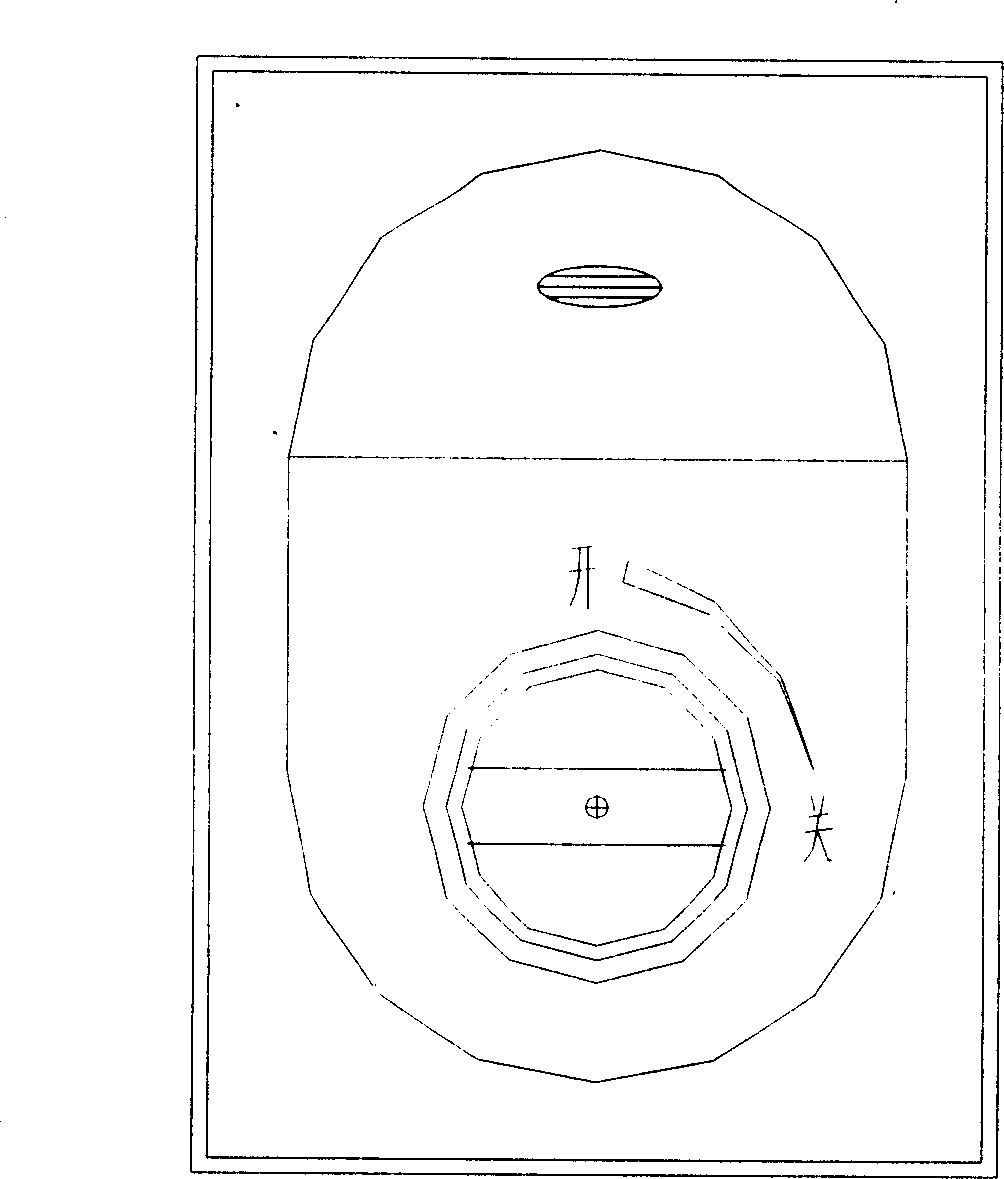

[0026] 3. Set the front valve of the buried wall stove in the groove. One end of the gas pipeline in the groove is connected to the gas meter, and the other end is connected to the special front valve installed in the groove. The other end of the front valve of the stove is connected to the rubber hose. , A buried wall sleeve is set at the outlet of the stove valve to facilitate the connectio...

Embodiment 2

[0030] In step 2, it also includes: installing effective partition materials at the parts where the buried pipes pass through the floor and through the walls, such as filling the middle of the casing with flexible sealing materials, and smoothing the ends with cement mortar to prevent gas from blowing out at various gas-using parts.

Embodiment 3

[0032] On the step of embodiment 1, following steps can be added:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com