Image forming apparatus and process cartridge

An imaging device and device technology, applied in the fields of electrical recording process equipment, electrical recording technology, optics, etc. that apply charge patterns, can solve the problems of undeveloped photoreceptor, blurred image and black spots, and easy generation of image memory, etc. Achieve the effect of suppressing blur and black spots, suppressing image memory, suppressing blur and black spots and image memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0274] The preparation method of the spherical toner is not particularly limited, and a known method can be used for preparation. For example, any one of the following methods is used: kneading and pulverizing; a method including obtaining particles by kneading and pulverizing, and then adjusting the shape of the particles by mechanical impact, force or thermal energy; emulsion polymerization; and a dissolution-suspension method. In one embodiment, the spherical toner obtainable using any of the methods described above is a core to which aggregated particles are adhered, followed by heating and melting, thereby producing a toner having a core-shell structure. In one embodiment, when the external additive is added, the toner is prepared by mixing the spherical toner and the external additive with a Henschel mixer or a V-type mixer. When a spherical toner is produced by a wet method, external additives may be added by a wet method.

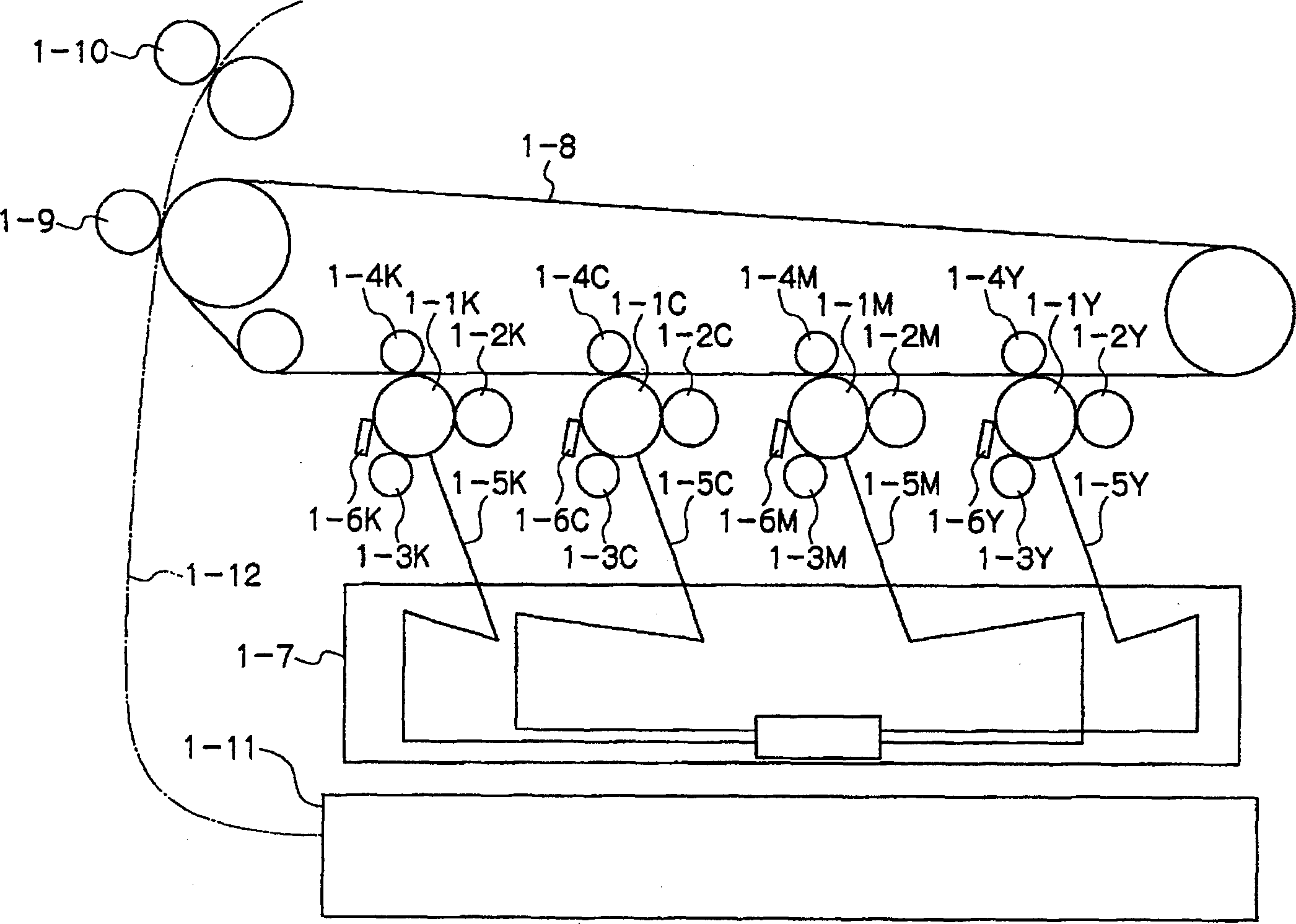

[0275] The intermediate transfer member 1-8 ...

Embodiment 1

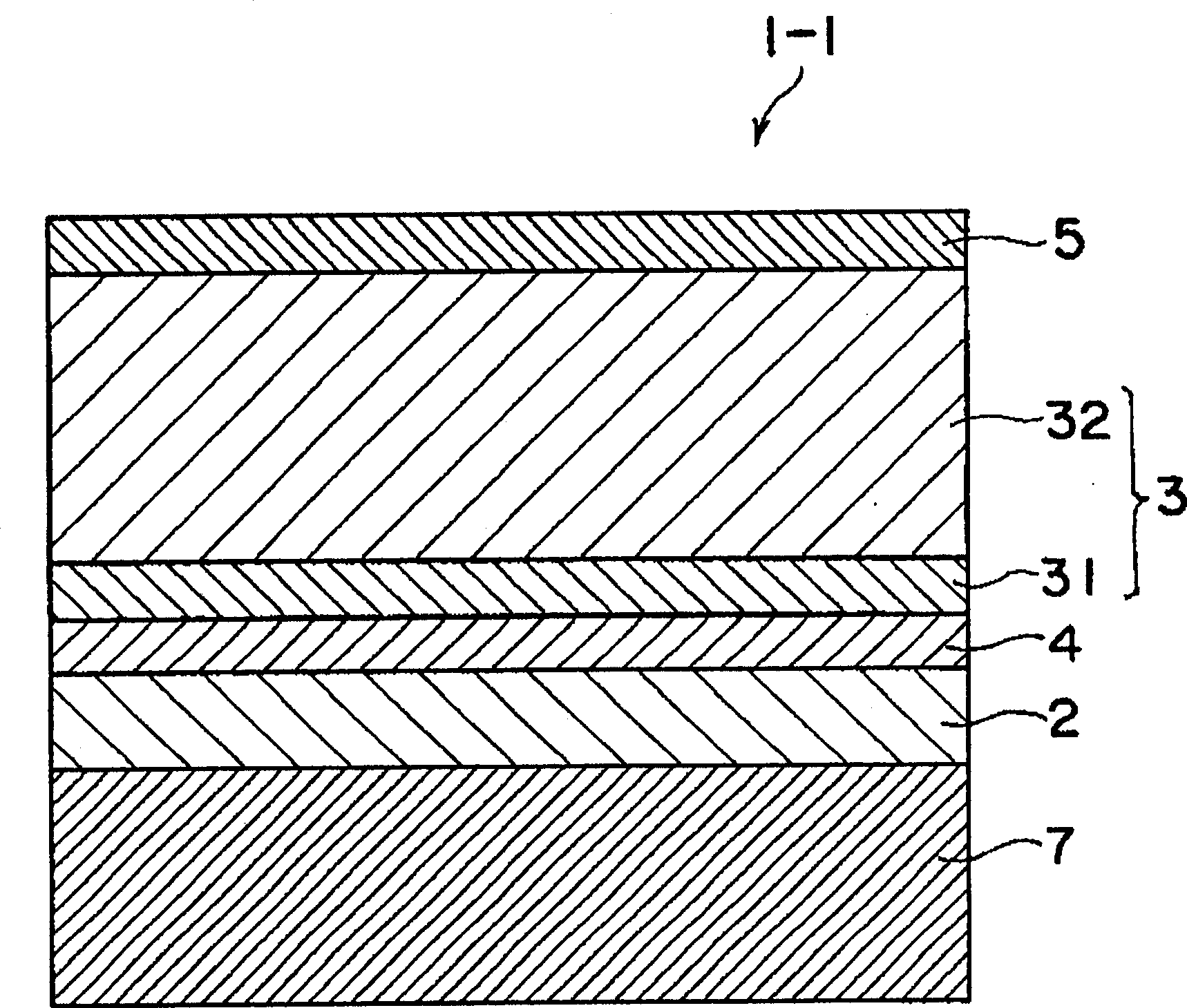

[0287] Under stirring, 100 parts by weight of zinc oxide (average particle diameter 70nm, specific surface area 15m 2 / g, produced by Tayka Corporation) was mixed with 500 parts by weight of tetrahydrofuran. 1.25 parts by weight of a silane coupling agent (KBM603 produced by Shin-etsu Chemical Co., Ltd.) was added thereto, and the mixture was stirred for 2 hours. Then tetrahydrofuran was distilled off under reduced pressure to obtain zinc oxide particles coated with a silane coupling agent, which were calcined at 120° C. for 3 hours to obtain a surface-treated zinc oxide pigment.

[0288] 15 parts by weight of butyral resin (BM-1 produced by Sekisui Chemical Co., Ltd.) was dissolved in 85 parts by weight of methyl ethyl ketone to obtain a solution, and 38 parts by weight of the resulting solution was mixed with 60 parts by weight of the zinc oxide pigment obtained above, 25 parts by weight Parts of methyl ethyl ketone, 0.6 parts by weight of alizarin and 13.5 parts by weight ...

Embodiment 2~4

[0293] An electrophotographic photoreceptor was produced in the same manner as in Example 1 except that the metal oxide and acceptor compound for surface treatment were changed to those shown in Table 1. The properties of the obtained photoreceptor were evaluated in the same manner as in Example 1. The results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com