Double temperature cold water unit for air conditioning system

A technology for chillers and air conditioning systems, applied in air conditioning systems, refrigerators, irreversible cycle compressors, etc., can solve the problems of difficult construction, difficult to popularize, and low energy efficiency of units, and achieves easy popularization and popularization. Economic and social benefits, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

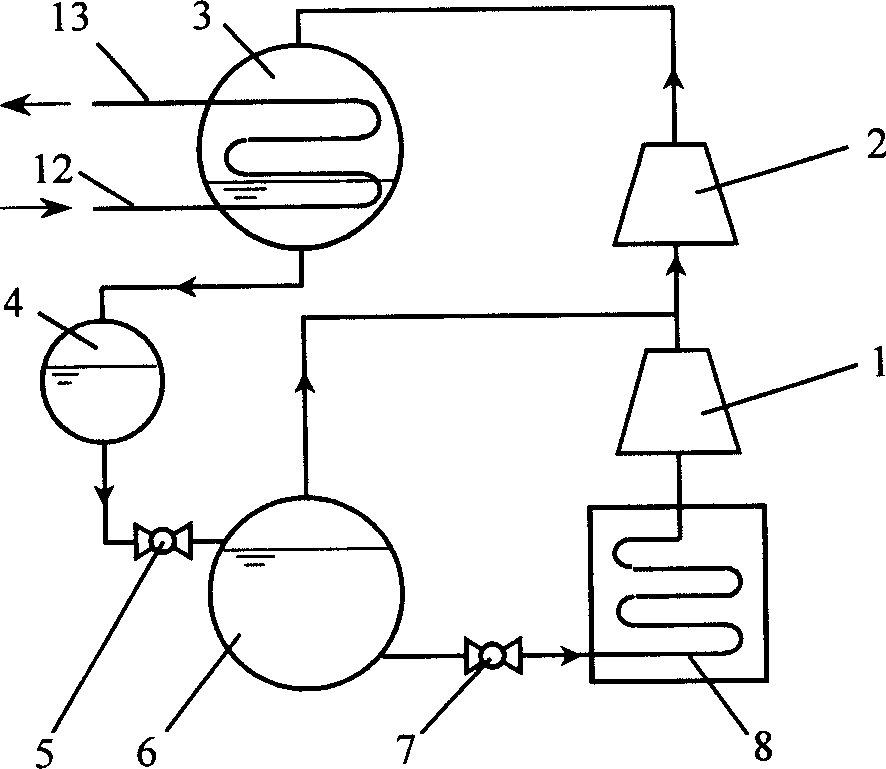

Embodiment 1

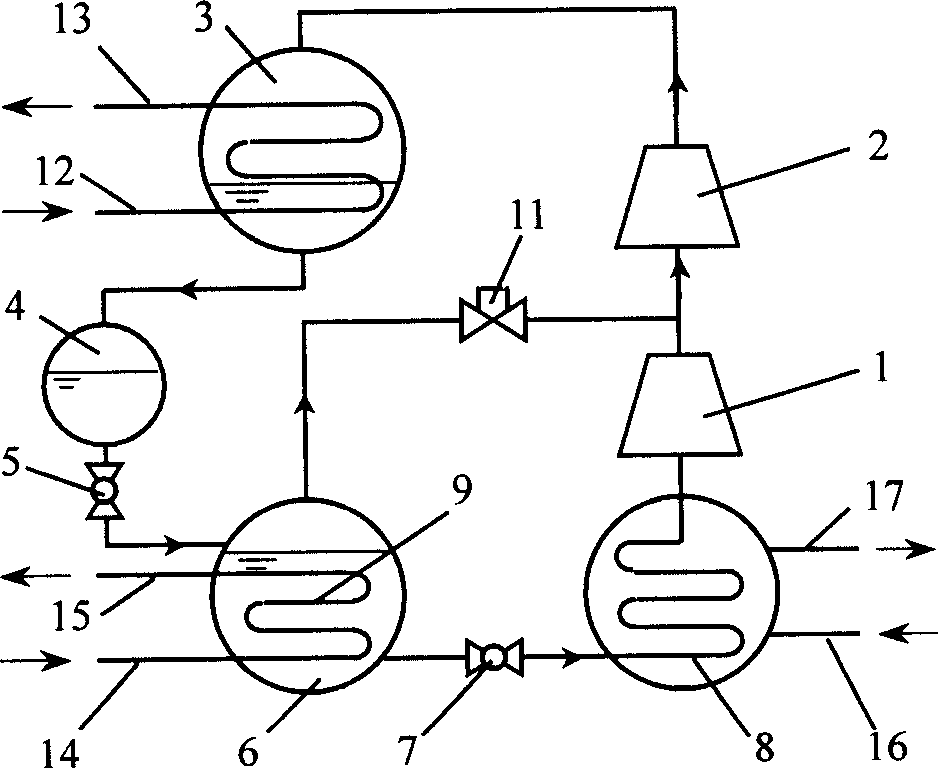

[0020] Such as figure 2 As shown, a dual-temperature chiller with independent high-pressure and low-pressure compressors is used. The dual-temperature chiller is a two-stage compression refrigeration cycle with two-stage throttling and incomplete cooling in the middle. It consists of a low-pressure stage compressor 1 and a high-pressure stage compressor 2. A two-stage compressor, a condenser 3, a liquid receiver 4, and a high-pressure stage Throttle valve 5, intercooler 6, low pressure stage throttle valve 7, low temperature evaporator 8, high temperature evaporator 9 and evaporation pressure regulating valve 11 constitute. Wherein the high temperature evaporator 9 is a cooling coil heat exchanger, which is arranged inside the intercooler 6 . When the unit is running, the high-temperature evaporator 9 is immersed in the medium-temperature liquid refrigerant throttled by the high-pressure stage throttle valve 5, and medium-temperature cold water passes through the interior of...

Embodiment 2

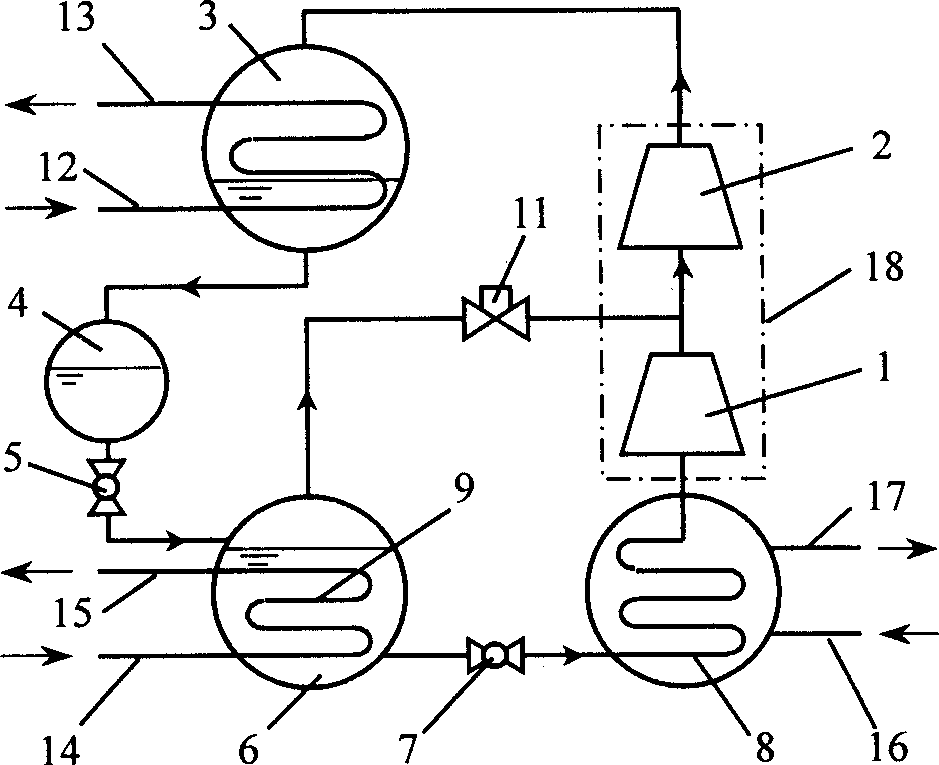

[0025] Such as image 3 As shown, in the above embodiment, the difference is that the two-stage compressor composed of the low-pressure stage compressor 1 and the high-pressure stage compressor 2 is a single-unit two-stage compressor 18, which can simplify the structure of the chiller. The outlet pipe of the evaporating pressure regulating valve 11 is connected to the connecting pipeline between the discharge pipe of the low-pressure compressor 1 and the suction pipe of the high-pressure compressor 2 . Others are identical with embodiment one.

Embodiment 3

[0027] Such as Figure 4 As shown, in the first embodiment above, the difference is that the two-stage compressor composed of the low-pressure stage compressor 1 and the high-pressure stage compressor 2 adopts centrifugal, screw, and scroll compressors with intermediate air supplementation. The quasi-two-stage compressor 19 with continuous compression feature can further simplify the unit structure, and the outlet pipe of the evaporation pressure regulating valve 11 is directly connected to the intermediate gas supply port of the quasi-two-stage compressor 19 . Others are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com