Multi-tier rope harness for installing a fabric into a papermaking machine

A multi-layer, fabric technology, applied in paper machine, textile and paper making, paper making, etc., can solve problems such as difficulty in stitching, concentration, stitching, and difficulty in guiding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

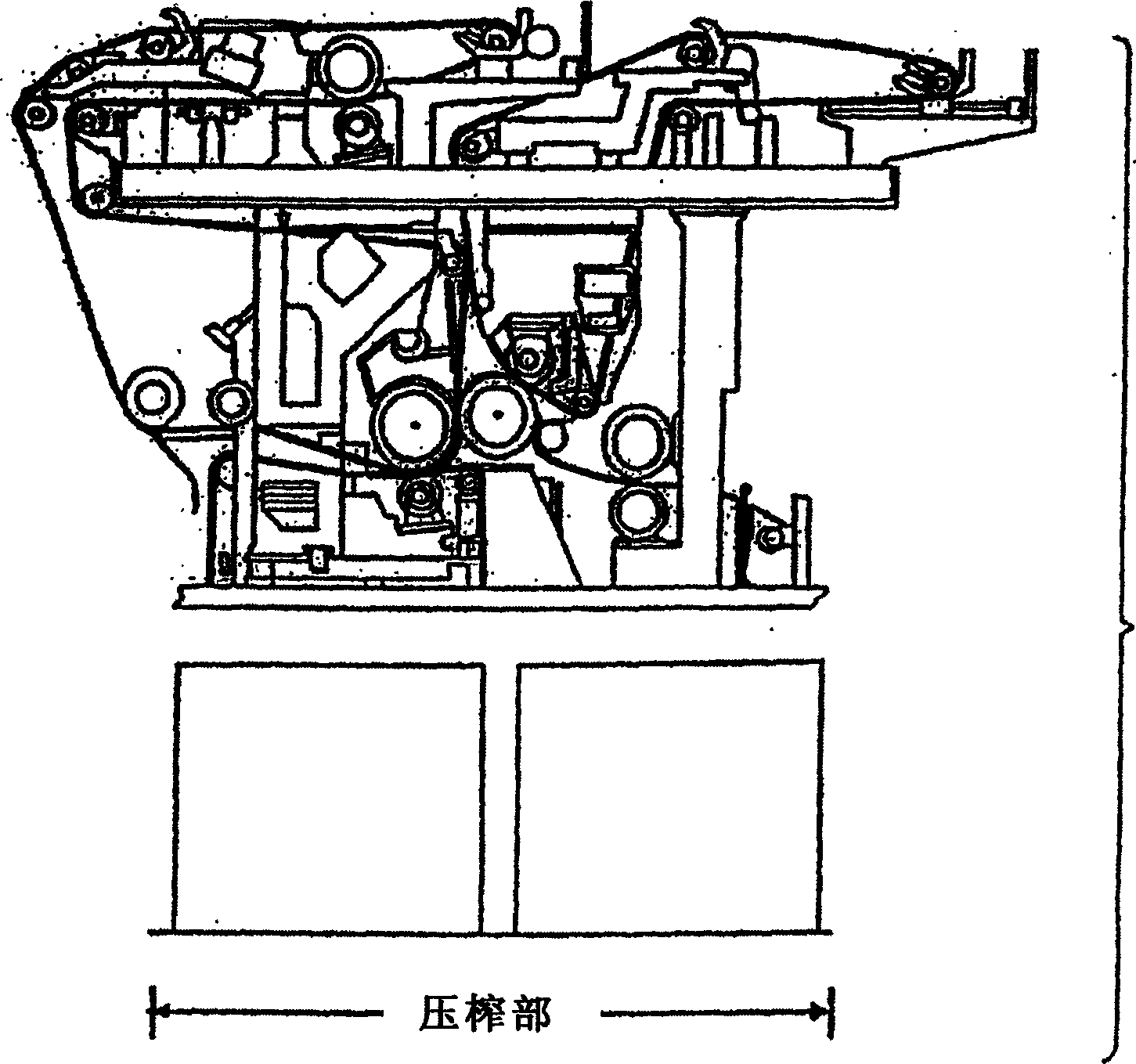

[0036] first, figure 2 A side view of the press section of a paper machine is shown. image 3 A side view of a typical paper machine dryer section is shown. The path of the fabric used for these parts is shown in the figure. The present invention is used to load fabrics into such paper machines.

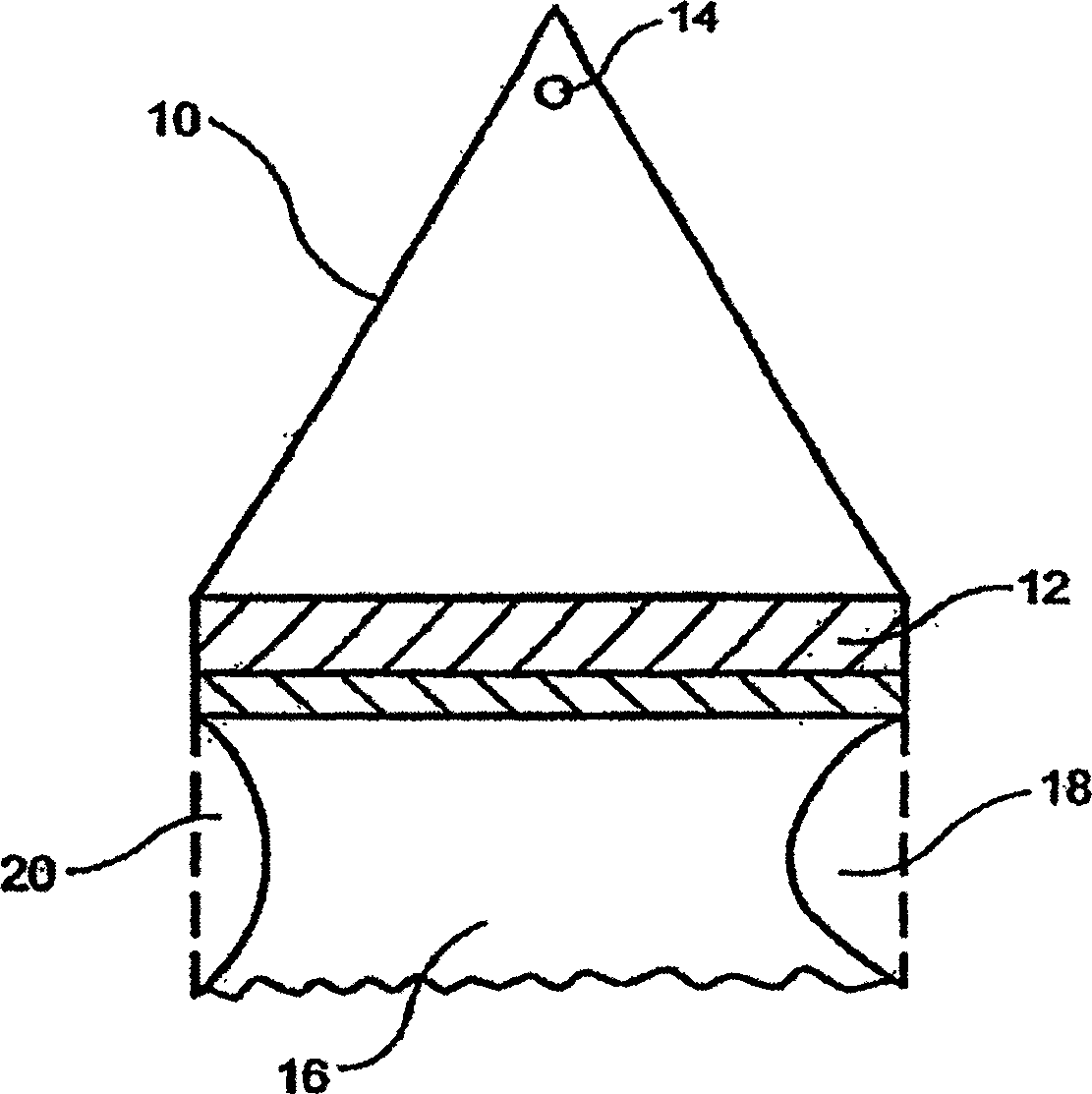

[0037] The multi-ply fabric loading harness of the present invention is a rope harness attached to a guide to assist in loading the fabric into the paper machine. The harness is self-balancing and comprises at least two layers, wherein each layer is made from a continuous length of rope. The guide is supported in its transverse direction by rigid elements. For example, metal strips can be inserted across the entire width of the guide. The first layer (or stage) of cord is formed by securing the cord to the hole in one edge of the guide, passing the cord loosely in loops through a series of holes in the transverse direction of the guide, and The end is fixed to the hole in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com