Method for regenerating urea dehydrogenation noble metal catalyst

A precious metal catalyst, dehydrogenation technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. consumption, no unsafe hazards, and the effect of saving regeneration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

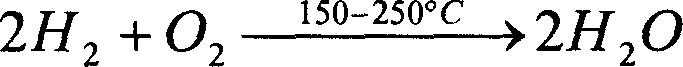

Image

Examples

Embodiment 1

[0017] Embodiment 1: Get 50ml of industrial deactivated TH-3 type urea dehydrogenation noble metal catalyst, soak with concentration 15wt% ammonium oxalate aqueous solution, solid-liquid volume ratio is 1: 3, soak for 4 hours, take out catalyst and wash with deionized water for 3 After the second time, it was dried at 120°C for 2 hours, and the activity of the regenerated catalyst was measured in the laboratory. The results are shown in Table 1.

Embodiment 2

[0018] Embodiment 2: get industrial inactivation TH-2 Type urea dehydrogenation noble metal catalyst 50ml, soaked in 3wt% ammonium tartrate aqueous solution, solid-liquid volume ratio is 1:5, soaked for 8 hours, took out the catalyst and washed it with distilled water for 3 times, then placed it in 120°C and dried it for 2 hours, the laboratory The activity of the catalyst after regeneration was measured, and the results are shown in Table 1.

Embodiment 3

[0019] Embodiment 3: Get 50ml of industrial deactivated TH-3 type urea dehydrogenation noble metal catalyst, soak with concentration 10wt% ammonium citrate aqueous solution, solid-liquid volume ratio is 1: 3, soak for 4 hours, take out catalyst and wash with deionized water After 3 times, it was dried at 120°C for 2 hours, and the activity of the regenerated catalyst was measured in the laboratory. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com