Method for font printing-preparation of tissue slice, and fill-up of tissue chip

A sectioning and histological technology, applied in the field of sectioning with carrier adhesion, can solve the problems of tissue point inconsistency, low pass rate of tissue chip products, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1 Tissue chip slice preparation

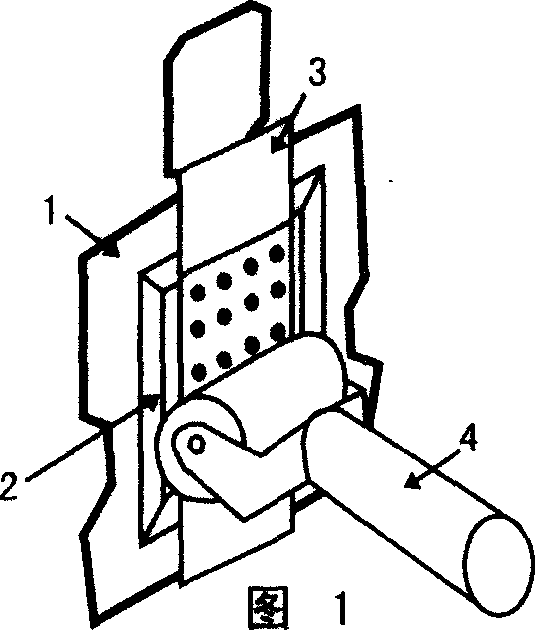

[0024] The first step is shown in Figure 1: the paraffin tissue array block (2) is fixed on the sample holder (1) of the microtome, and the surface of the sample is cut and trimmed with the microtome in the trimming mode to fully expose the target, and a section with organic adhesion is taken. Adhesive adhesive tape (3) (the area is slightly larger than the target), remove the back bottom plate, stick to the surface of the target through the adhesive on the tape, and gently roll the film with the rubber roller (4) to make the two are tightly adhered.

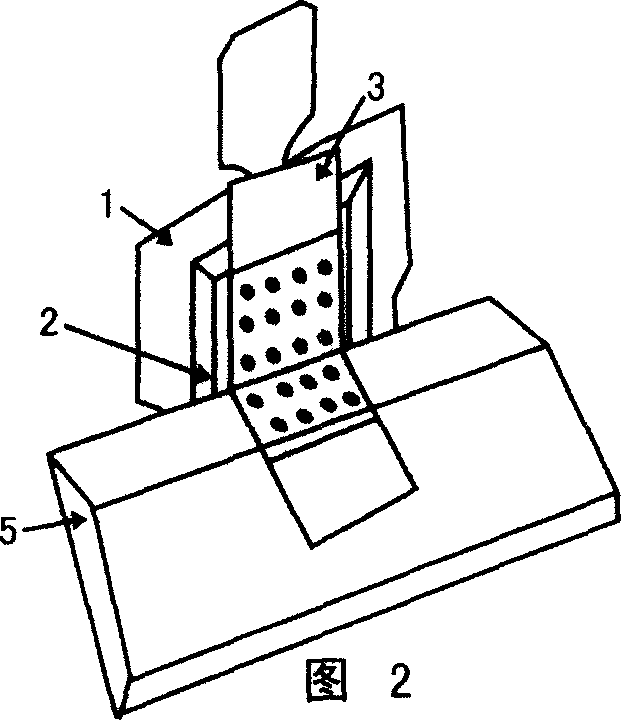

[0025] The second step is shown in Figure 2: use the tissue microtome blade (5) to remove the adhesive tape (3) with the tissue chip attached from the paraffin tissue array block ( 2) The surface is cut off.

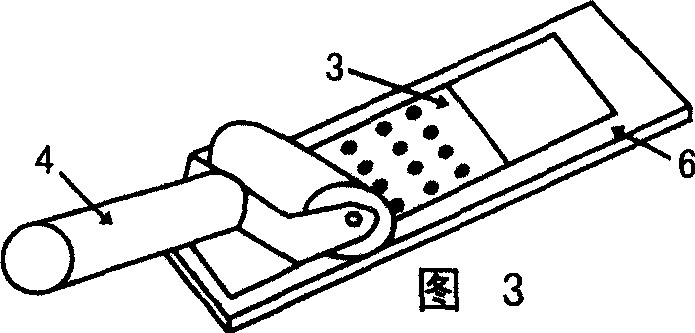

[0026] The third step is shown in Figure 3: stick the adhesive tape (3) with the tissue chip section on the passing glass slide (6), and roll it with a rubber roller (4) t...

example 2

[0028] Example 2 is used to fill in missing tissue samples in tissue microarrays

[0029] This method can also be used to repair missing tissue samples in tissue microarrays, that is, the movable type repair method.

[0030] The first step is as Figure 6 Shown: Tissue cores are extracted from pathological wax blocks in the process of making tissue microarrays. The thickness of pathological wax blocks is different, and the length of tissue cores is also different. Slicing tissue cores with different lengths into tissue arrays may result in the loss of Some sample points are missing, and mistakes may also occur when extracting tissue cores. The sample points are different from the actual array design. We can remove the wrong sample points to form a tissue microarray with missing parts.

[0031] The second step is shown in Figure 7: arrange the tissue cores to fill the sample points in a blank wax block according to the array design, and fix the wax block (11) containing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com