Li4Ti5O12 cathode material cladden on surface of spinel LiMn2O4 and preparation method thereof

A technology of surface coating and electrode materials, which is applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve problems affecting electrochemical performance, etc., and achieve low price, simple coating process, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

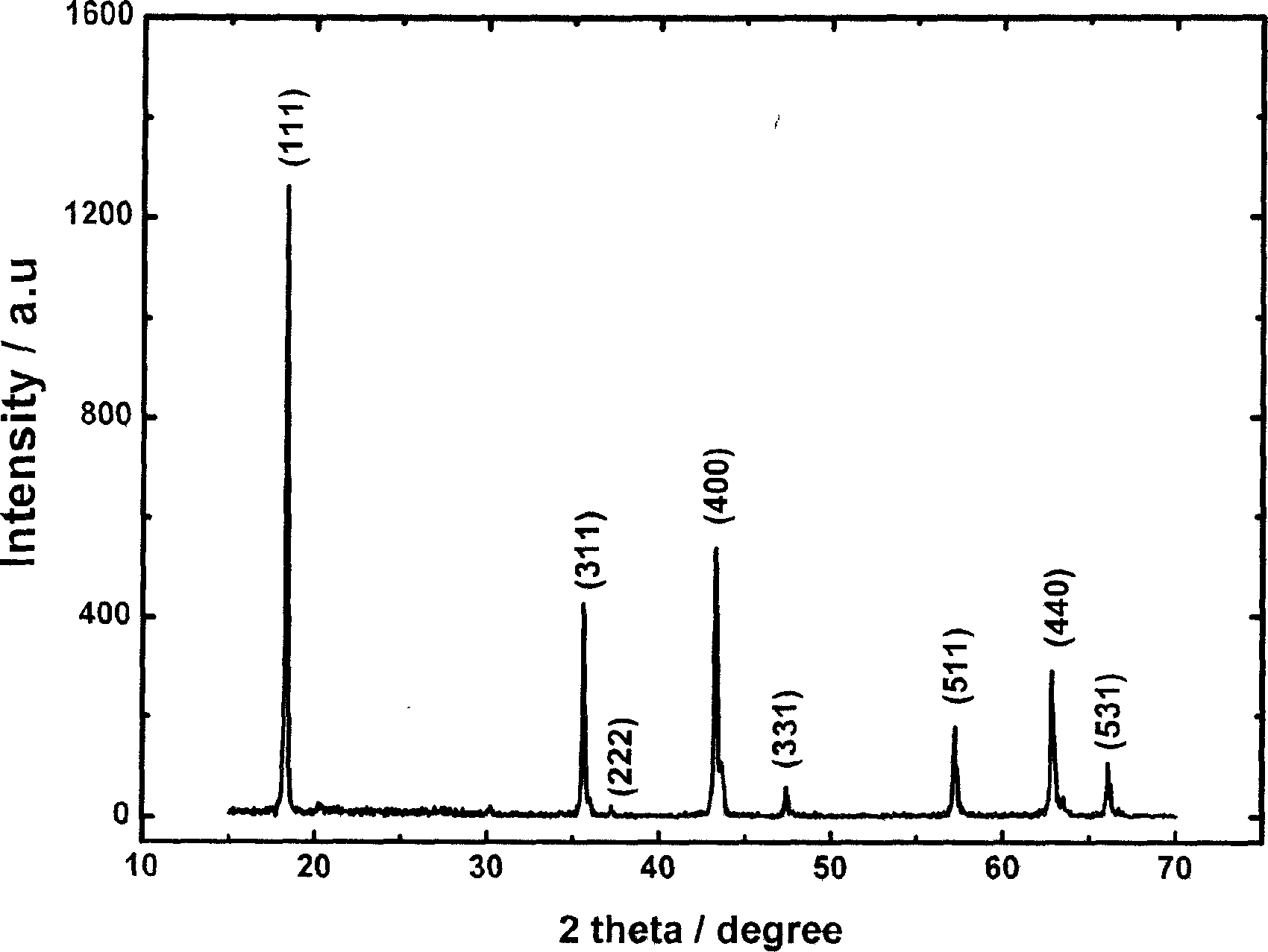

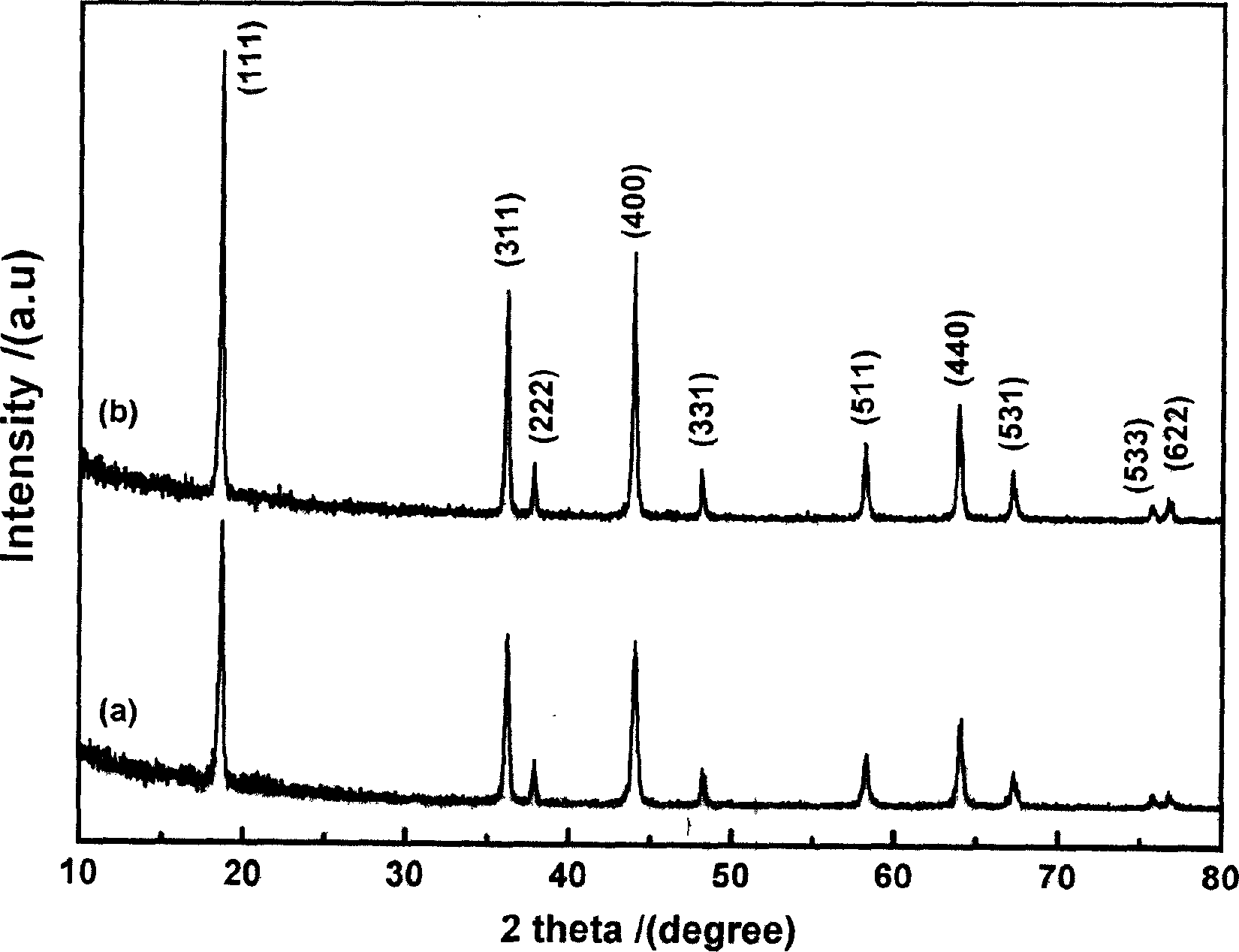

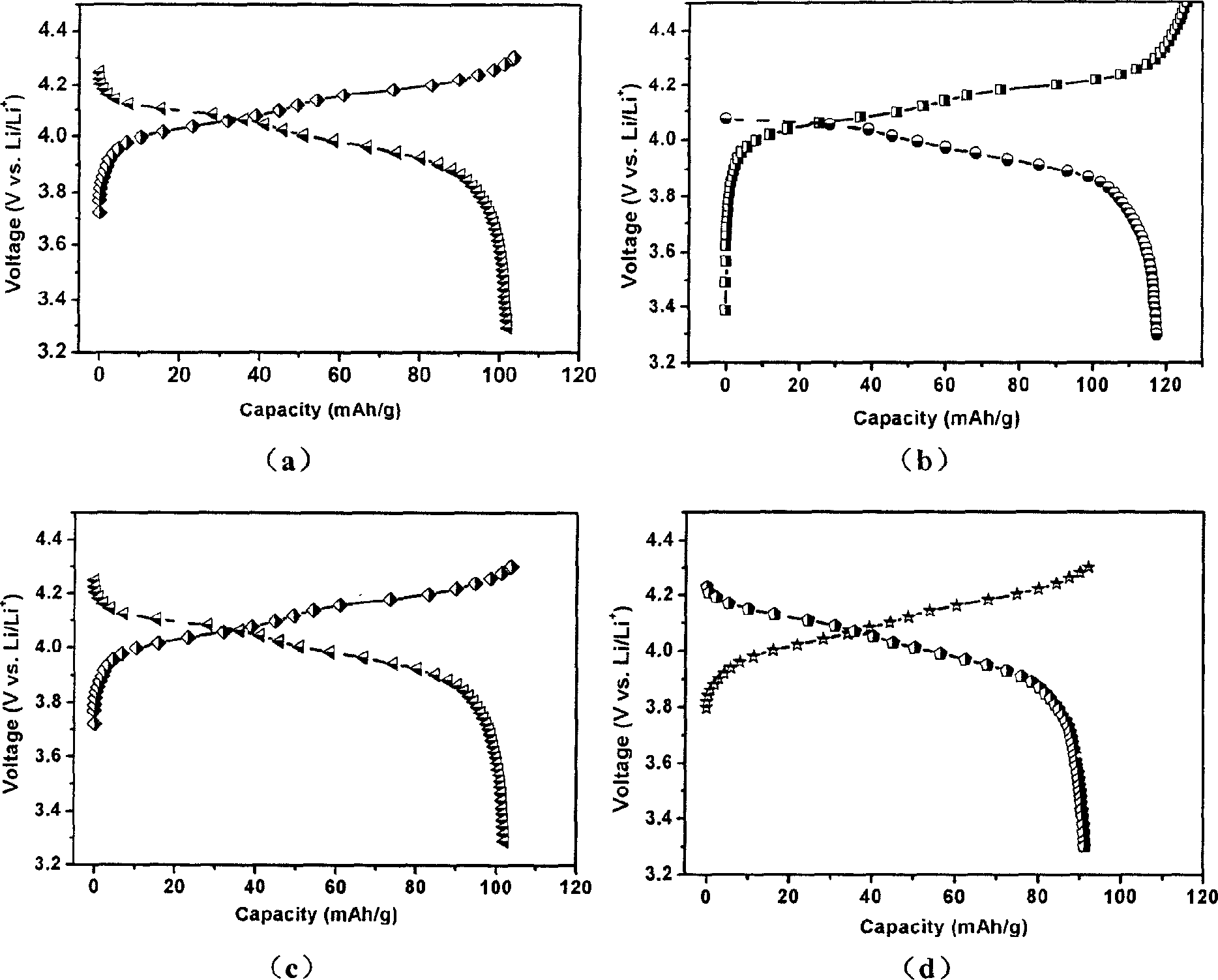

Embodiment 1

[0022] Add 0.2303g of lithium acetate into a mixed solution of 2ml of absolute ethanol, 0.25ml of deionized water, and 0.2ml of glacial acetic acid under stirring. After lithium acetate is completely dissolved, slowly transfer it to 0.9701g of butyl titanate solution under stirring. A pale yellow transparent sol was formed, and after stirring for 30 minutes, 10 g LiMn was added 2 o 4 Powder, continue to stir for 4 hours, the sol gradually turns into a gel, and the gel is dried in an oven at 150°C overnight to become a dry gel powder, which is directly sintered in a muffle furnace at 800°C for 24 hours , naturally lowered to room temperature, 1% molLi 4 Ti 5 o 12 Coated LiMn 2 o 4 powder.

Embodiment 2

[0024] Add 0.2326g of lithium acetate into a mixed solution of 3ml of absolute ethanol, 0.28ml of deionized water, and 0.25ml of glacial acetic acid under stirring. After the lithium acetate is completely dissolved, slowly transfer it to 0.9800g of butyl titanate solution under stirring. A pale yellow transparent sol was formed, and after stirring for 30 minutes, 5gLiMn was added 2 o 4 Powder, continue to stir for 4 hours, the sol gradually turns into a gel, put the gel in an oven at 150°C and dry overnight to become dry gel powder, and sinter the dry gel powder directly in a muffle furnace at 800°C for 24 hours , naturally lowered to room temperature, 2% molLi 4 Ti 5 o 12 Coated LiMn 2 o 4 powder.

Embodiment 3

[0026]Add 0.2115g of lithium acetate into a mixed solution of 3.1ml of absolute ethanol, 0.23ml of deionized water, and 0.2ml of glacial acetic acid under stirring. After lithium acetate is completely dissolved, slowly transfer it to 0.8911g of butyl titanate solution under stirring , forming a light yellow transparent sol, after stirring for 30 minutes, adding 3gLiMn 2 o 4 Powder, continue to stir for 4 hours, the sol gradually turns into a gel, and the gel is dried in an oven at 150°C overnight to become a dry gel powder, which is directly sintered in a muffle furnace at 800°C for 24 hours , naturally lowered to room temperature, 3% molLi 4 Ti 5 o 12 Coated LiMn 2 o 4 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com