Organic eletroluminesence element

An electroluminescence element and electroluminescence technology, applied in the direction of electroluminescence light source, electrical element, electric light source, etc., can solve the problems of inability to achieve life, organic EL element not yet developed, long efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0118] [Example]

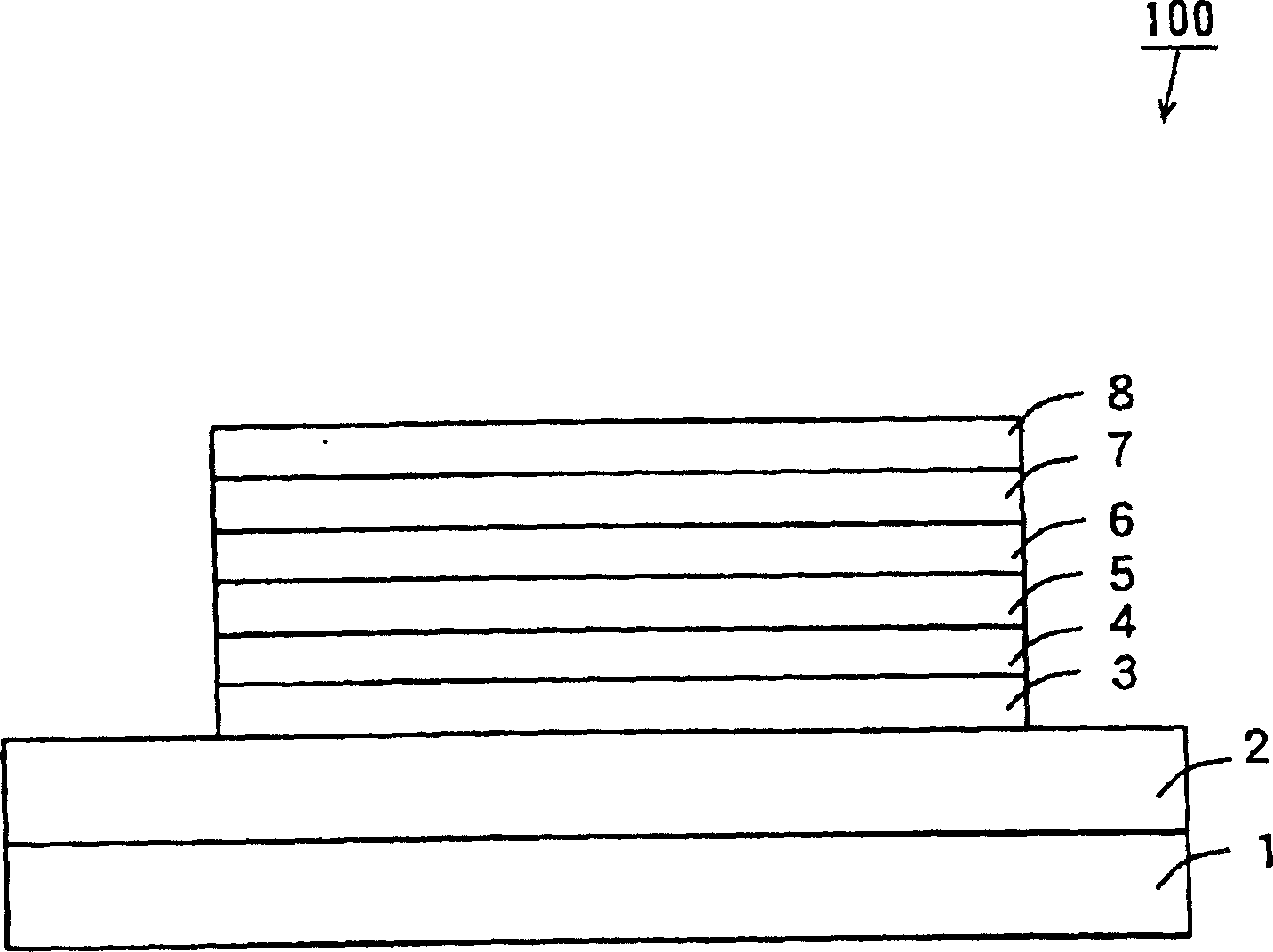

[0119] The structure of the organic EL element of this example is the same as that of the organic EL element 100 of the above-mentioned embodiment.

[0120] In this example, a driving voltage was applied between the hole injection electrode 2 and the electron injection electrode 8 of the organic EL element 100, and the luminous efficiency and lifetime of the organic EL element 100 were measured. In addition, the lifetime means the time until the luminance value of the organic EL element 100 decreases to 1 / 2 of the initial value.

[0121] The luminescent color of the organic EL element 100 is blue, the luminous efficiency is 11 cd / A, and the lifetime is 150 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com