Method for preparing chalkogenide thermoelectric film using liquid-phase chemical method

A chalcogenide, thermoelectric thin film technology, applied in liquid chemical plating, thermoelectric device manufacturing/processing, thermoelectric devices, etc., can solve the problems of high cost, large investment, difficult batch preparation, etc. The effect of high transduction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Solution preparation:

[0025] (1) 0.05mol / L H 2 SeO 3 Solution preparation: 0.005mol of SeO 2 (1.205g) was dissolved in water to a constant volume of 100ml solution to make a concentration of 0.05mol / L H 2 SeO 3 solution.

[0026] (2) 0.05mol / L BiCl 3 Solution preparation 0.0025mol BiCl 3 (0.788g) was dissolved in water and added 2ml hydrochloric acid to dilute to 50ml solution to make BiCl with a concentration of 0.05mol / L 3 solution.

[0027] (3) Preparation of Bi+Se mixed solution: take 12ml of 0.05mol / L H 2 SeO 3 solution and 8ml of 0.05mol / L BiCl 3 solution, mixed, and stirred for 30 minutes to prepare a Bi 2 Se 3 0.1mol / L Bi+Se precursor mixed solution with molecular formula ratio; set aside.

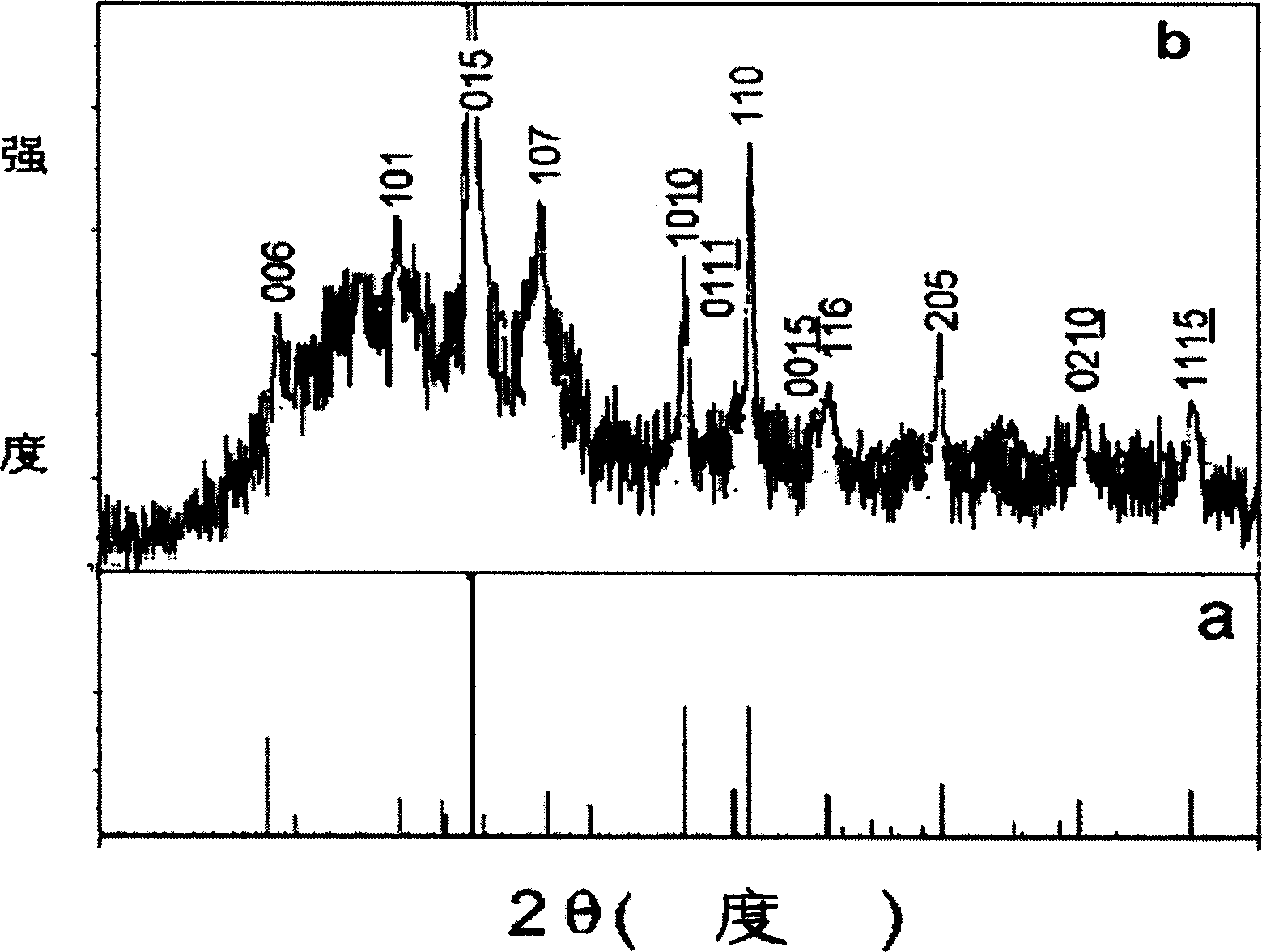

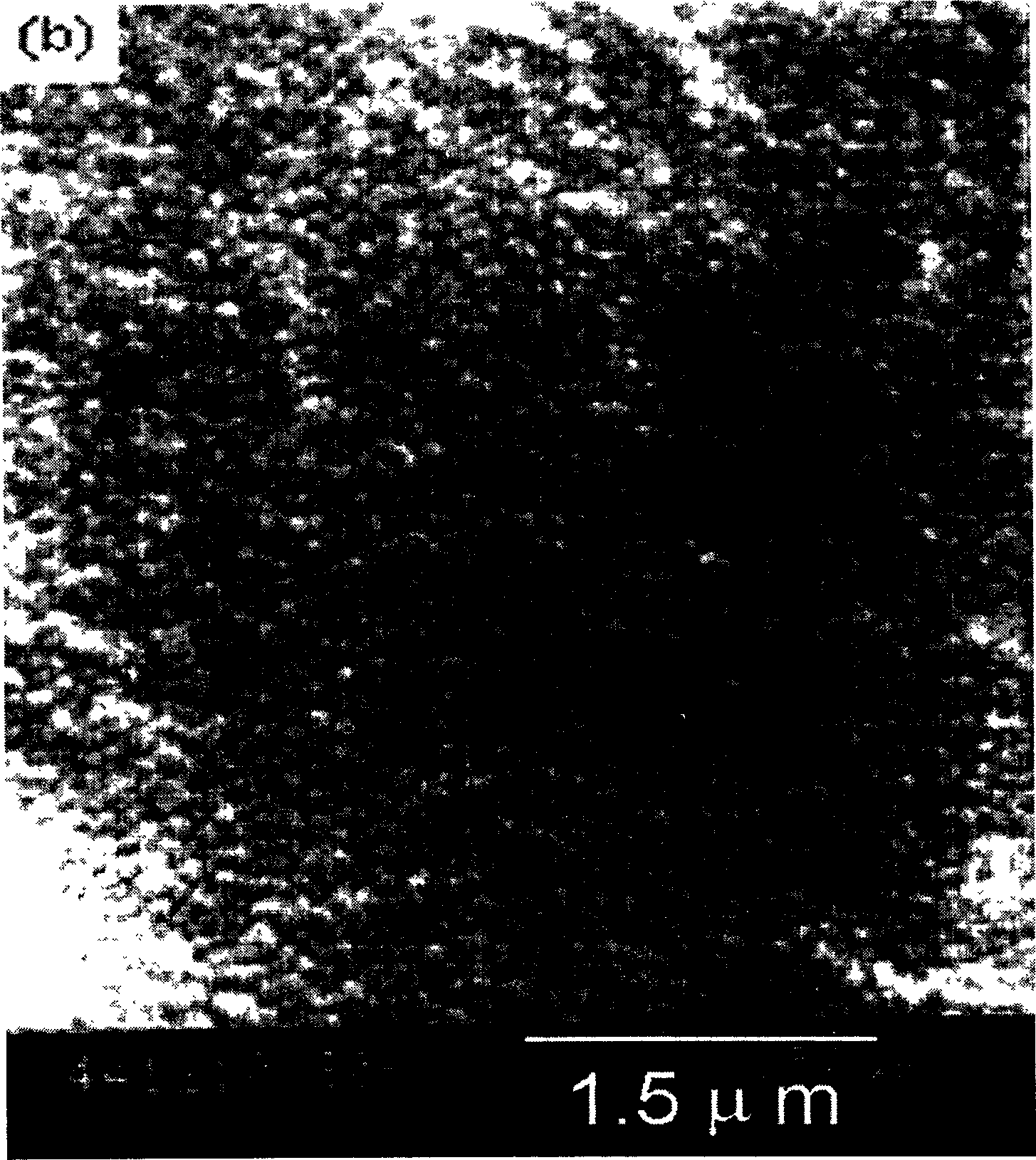

[0028] 2. Bi 2 Se 3 Film preparation:

[0029] (1) Spin coating: operate according to the general film spin method. The quartz glass substrate is boiled with sulfuric acid + hydrogen peroxide, deionized water, ethanol, acetone, etc., and cleaned under u...

Embodiment 2

[0035] 1. Solution preparation:

[0036] (1) 0.2mol / L H 2 SeO 3 Solution preparation: 0.02mol of SeO 2 (4.82g) was dissolved in water to a constant volume of 100ml solution to make a concentration of 0.2mol / L H 2 SeO 3 solution.

[0037] (2) 0.2mol / L BiCl 3 Solution preparation: 0.01mol BiCl 3 (3.53g) was dissolved in water and added 2ml hydrochloric acid to dilute to 50ml solution to make BiCl with a concentration of 0.2mol / L 3 solution.

[0038] (3) Preparation of Bi+Se mixed solution: take 12ml of 0.2mol / L H 2 SeO 3 solution and 8ml of 0.2mol / L BiCl 3 solution, mixed, and stirred for 30 minutes to prepare a Bi 2 Se 3 0.4mol / L Bi+Se precursor mixed solution with molecular formula ratio. spare.

[0039] 2. Bi 2 Se 3 Film preparation:

[0040] Other steps are with example 1.

Embodiment 3

[0042] 1. Solution preparation:

[0043] (1) 0.5mol / L H 2 SeO 3 Solution preparation: 0.05mol of SeO 2 (12.05g) was dissolved in water to a constant volume of 100ml solution to make a concentration of 0.5mol / L H 2 SeO 3 solution.

[0044] (2) 0.5mol / L BiCl 3 Solution preparation 0.025mol BiCl 3 (7.88g) was dissolved in water and added 2ml hydrochloric acid to dilute to 50ml solution to make BiCl with a concentration of 0.5mol / L 3 solution.

[0045] (3) Preparation of Bi+Se mixed solution: take 12ml of 0.5mol / L H 2 SeO 3 solution and 8ml of 0.5mol / L BiCl 3 solution, mixed, and stirred for 30 minutes to prepare a Bi 2 Se 3 1mol / L Bi+Se precursor mixed solution with molecular formula ratio. spare.

[0046] 2. Bi 2 Se 3 Film preparation:

[0047] Other steps are with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com