Method for producing three-component self-crimped filament yarn

A three-component, self-crimping technology, used in filament/thread forming, conjugated synthetic polymer rayon, textiles and papermaking, etc. Improved properties, smaller modulus, and finer fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

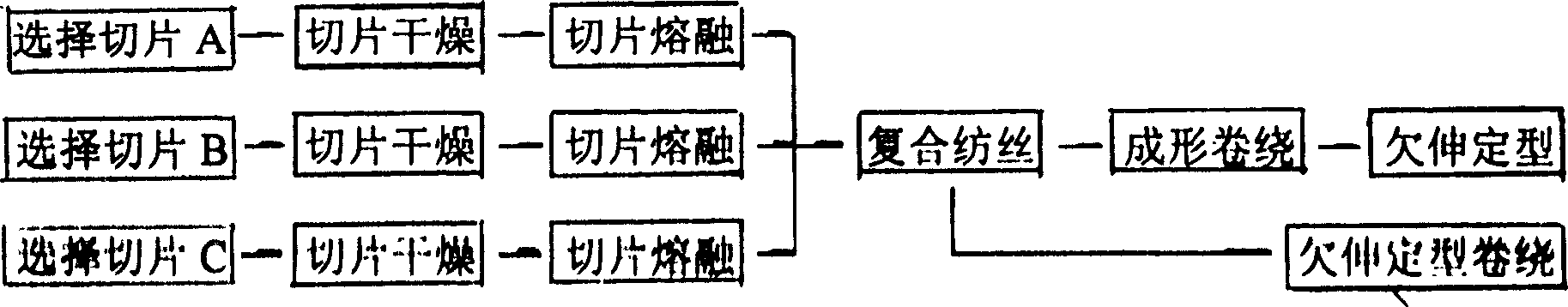

Method used

Image

Examples

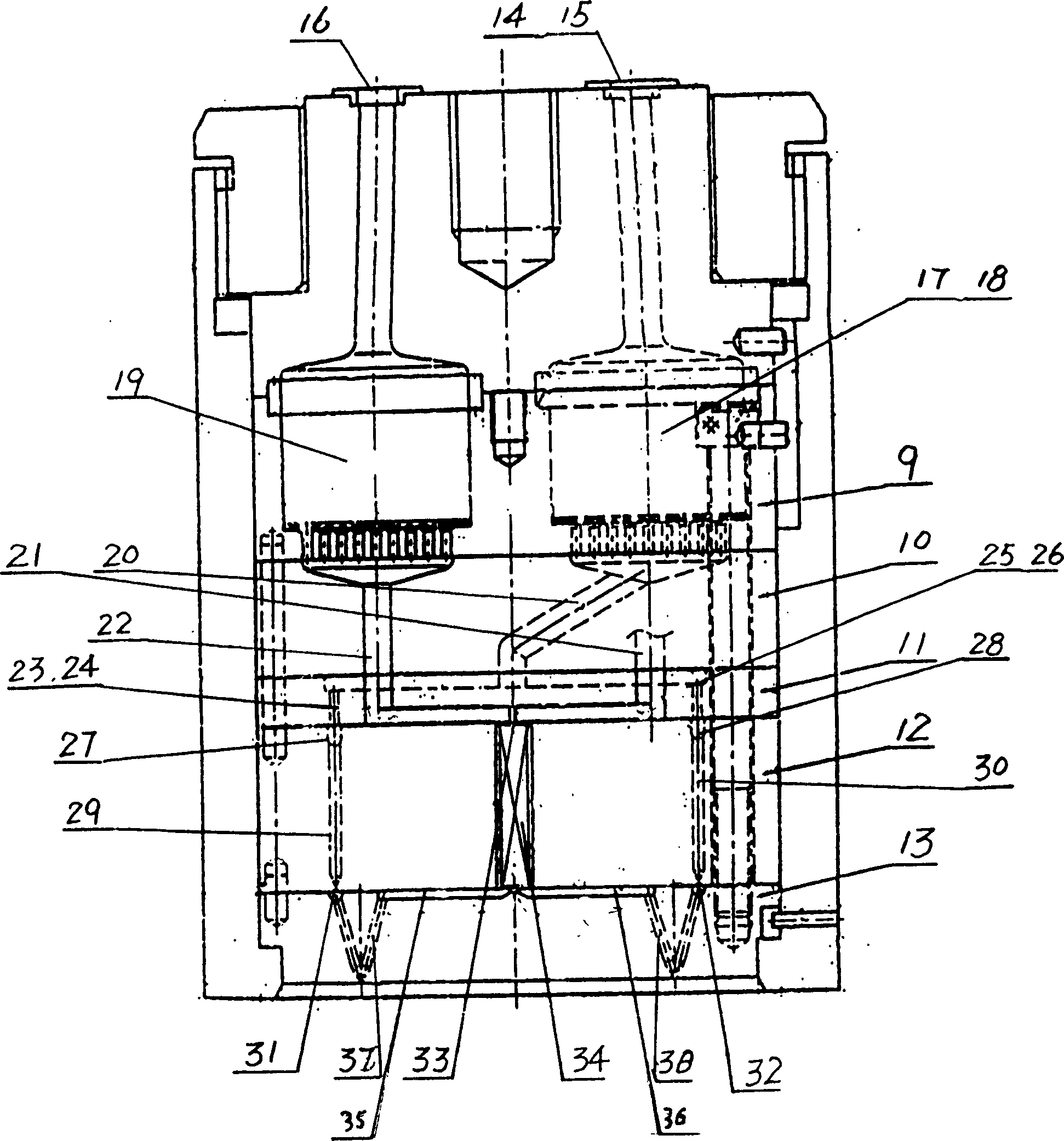

Embodiment 1

[0031] Choose DPET / PET / COP with different intrinsic viscosities as the three polyester chip components, select a certain ratio, and use polyester chips to select slices, dry slices, slices, melt, composite spinning, forming, winding, understretching and setting. The method produces 167dtex / 24FPOY, and its final product is 111dtex / 24f three-component self-crimping filament, and the intrinsic viscosity (IV) of the three-component DPET / PET / COP is 0.496 / 0.646 / 0.720 respectively. Three screw extruders for DPET / PET / COP three-component chip melting are JWM55 / 25C, JWM40 / 25C, JWM30 / 25C; three metering machines for three-component DPET / PET / COP composite spinning The pump specifications are 1.8CC / R, 0.9CC / R, 0.6CC / R; the traction equipment used for cooling and winding in the forming and winding step is a BWA860T high-speed winding machine; the equipment used for the under-stretching and shaping step is Taicang The PQ668A type flattening machine of the Spinning Instrument Factory; the ins...

Embodiment 2

[0053] Choose PTT / PET / COP with different intrinsic viscosities as the three polyester chip components, select a certain ratio, and use polyester chips to choose a process of cutting into slices, drying, slices, melting, composite spinning, forming, winding, and understretching. The method produces 167dtex / 24FPOY, and the final product is 111dtex / 24f three-component self-crimping filament. The intrinsic viscosity (IV) of PTT / PET / COP three-component is 0.920 / 0.635 / 0.722 respectively. Three screw extruders for PTT / PET / COP or PET / PTT / COP three components are JWM55 / 25C, JWM40 / 25C, JWM30 / 25C; for PTT / PET / COP or PET / PTT / COP The specifications of the three metering pumps for the melting of three-component slices are 1.8CC / R, 0.9CC / R, and 0.6CC / R; the traction equipment used for cooling and winding in the forming and winding step is BWA860T high-speed winding; The equipment used for understretching and setting steps is the PQ668A flattening machine of Taicang Spinning Instrument Factor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com