Flame-resistant fireproof paper containing expansion graphite and producing method thereof

A technology of expansible graphite and a manufacturing method, applied in the field of papermaking, can solve the problems of incombustibility and fire prevention, and achieve the effects of simple manufacturing method, good fire prevention function and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

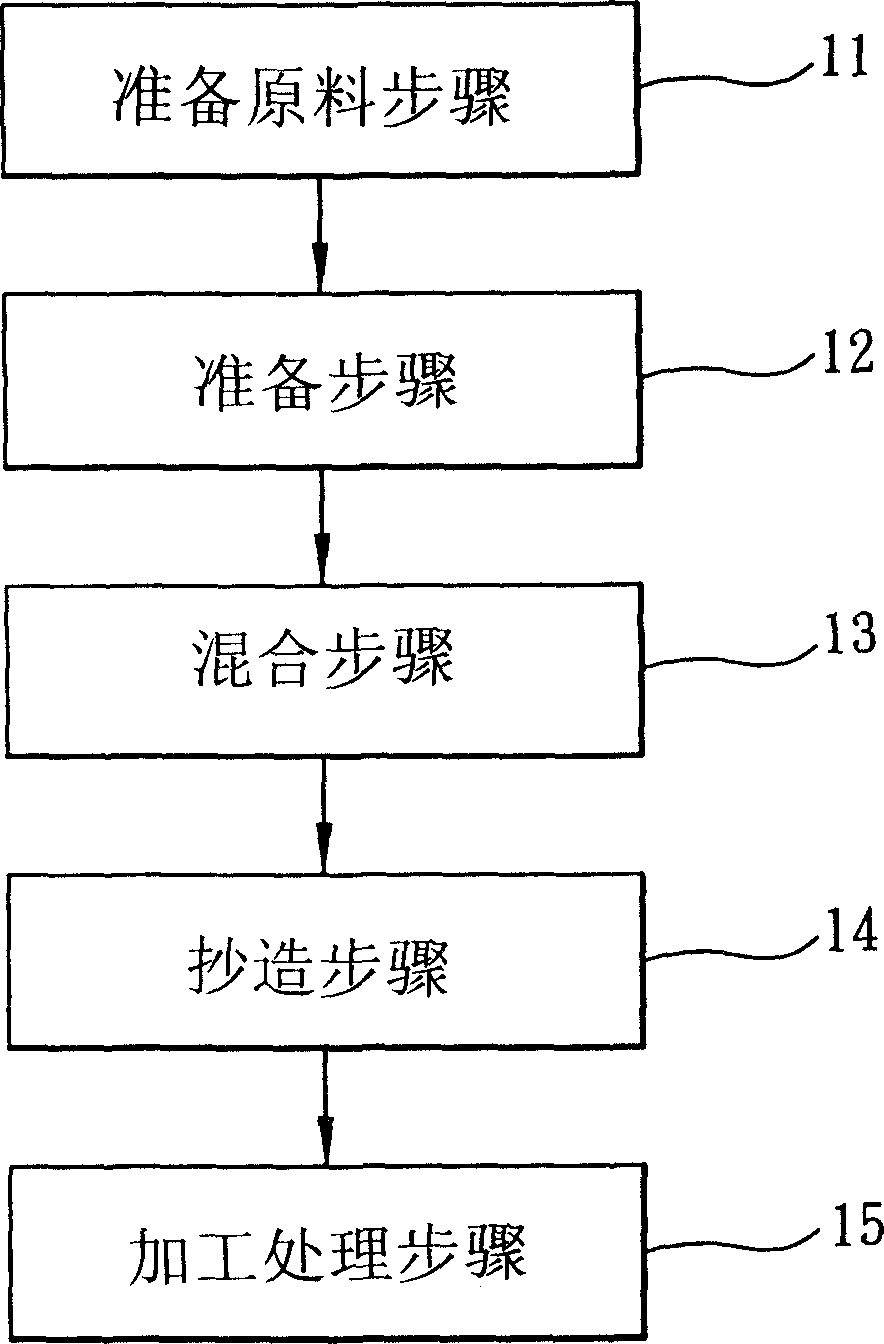

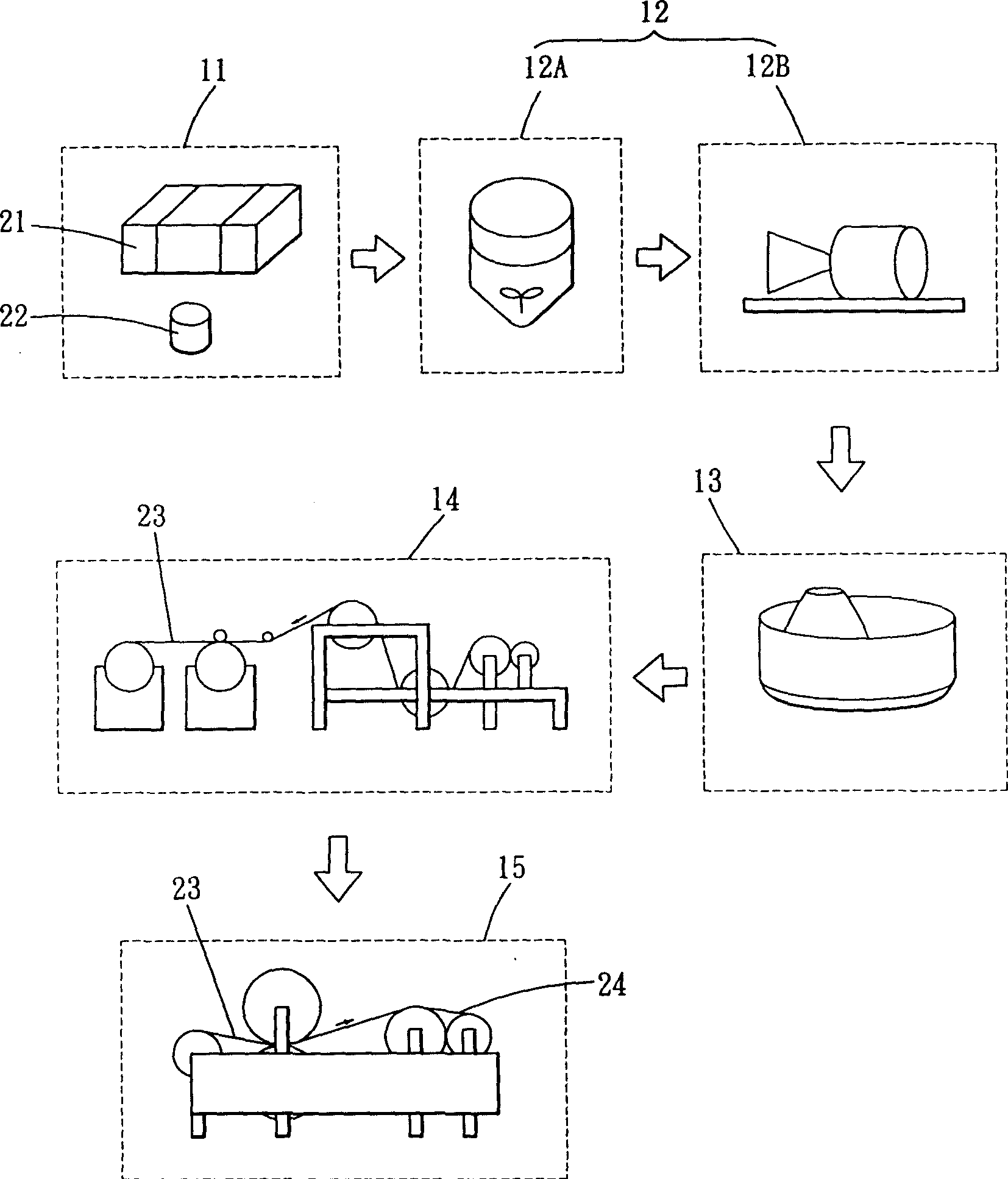

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is a kind of flame-retardant fire-proof paper containing expansive graphite and its manufacturing method. Regarding the composition of fire-proof paper, it includes: (a) expansive graphite with a weight percentage of 20% to 80% and evenly distributed, the expansive Graphite will expand when it encounters the fire port, and has sufficient flame resistance to block the transfer of the fire port; (b) the rest is evenly distributed pulp containing paper-making fibers.

[0029] More specifically, the fiber for papermaking includes a natural fiber for papermaking, and the natural fiber for papermaking is selected from one or more of wood pulp, hemp pulp, and cotton pulp. In addition, the fiber for papermaking includes a chemical fiber for papermaking, the chemical fiber for papermaking is selected from high melting point polyester fiber (refers to high melting point PET fiber, the PET is the abbreviation of Polyethylene terephthalate), low melting point p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com