Equipment for reacting sputtering

A kind of equipment and reaction technology, applied in the field of reactive sputtering equipment, can solve the problem of low sputtering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

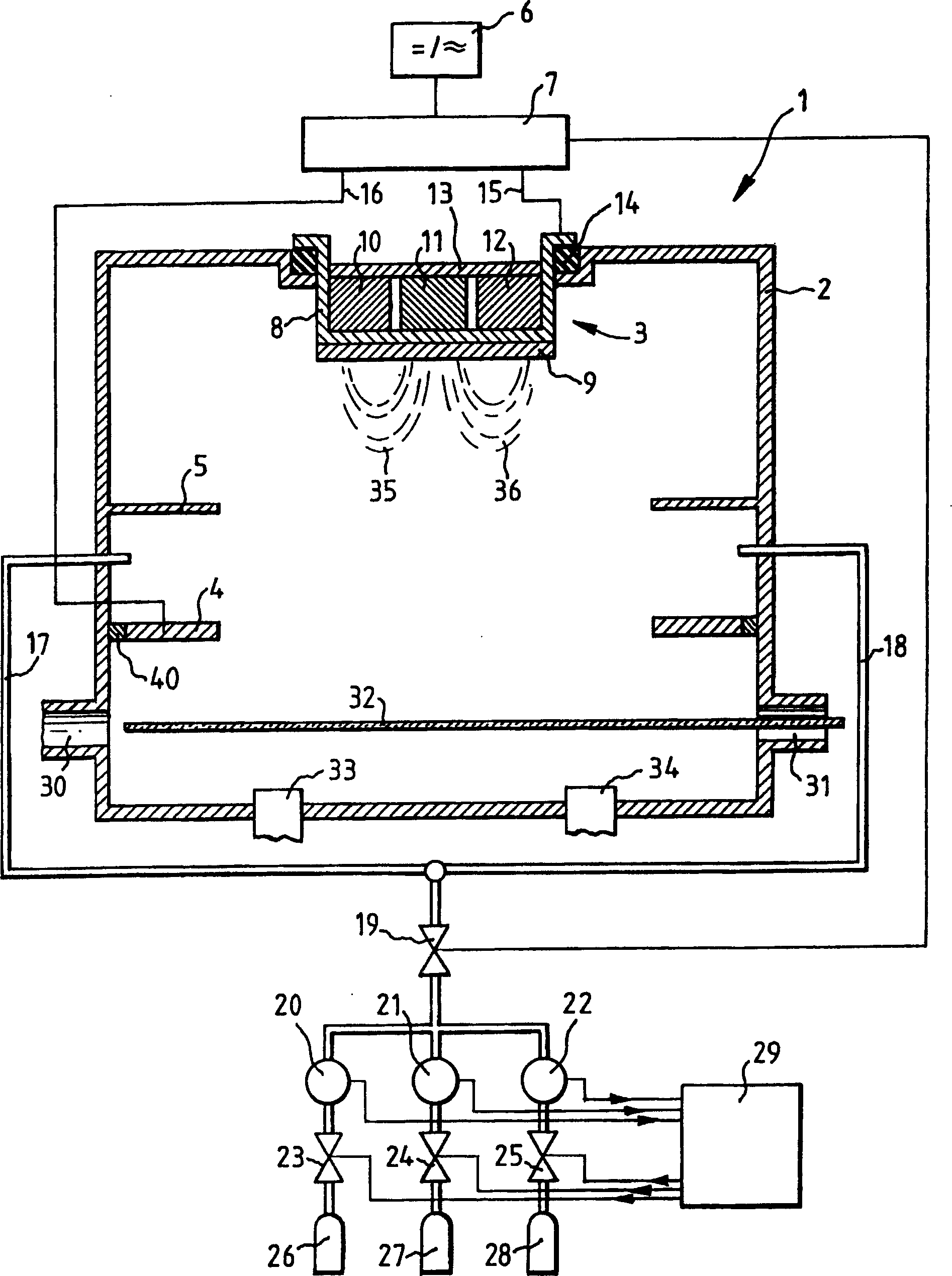

[0022] figure 1 The principle of the sputtering device 1 is shown, and the sputtering device 1 includes: a sputtering chamber 2 , a cathode 3 , an anode 4 , a protective plate 5 , a voltage source 6 and a regulating circuit 7 . The cathode 3 comprises a tubular cathode part 8 to which a target 9 to be sputtered is mounted by means of a flange. Three permanent magnets 10 , 11 , 12 are arranged on the tubular cathode part 8 , and the three permanent magnets 10 , 11 , 12 are connected to each other via a yoke 13 . The cathode part 8 bears on a seal 14 on the edge of the opening in the sputtering chamber 2 . The voltage of the voltage source 6 is conducted via one electrode 15 of the regulating circuit 7 to the cathode part 8 and via its other electrode 16 to the anode 4 . Even if the voltage of the voltage source 6 fluctuates, the regulation circuit 7 keeps the voltage output to the anode-cathode path constant. The fluctuation of the discharge voltage is mainly affected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com