Etching composition

A composition and etching technology, applied in the direction of clamping, supporting, positioning device, etc., can solve the problems of unstable ferric chloride, easy to be decomposed by hydrochloric acid, and the influence of Mo series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 12% by mass of hydrochloric acid, 3% by mass of acetic acid, 0.1% by mass of NH as additives 4 NO 3 and the rest of the ultrapure water were evenly mixed to produce an etching composition.

Embodiment 2~4 and comparative example 1~4

[0041] An etching composition was produced in the same manner as in Example 1 except that the composition was shown in Table 1 below.

[0042] Form a transparent conductive film (ITO film) by sputtering on a glass substrate, coat a photoresist and develop it, and fix the etching compositions of the above-mentioned Examples 1 to 4 and Comparative Examples 1 to 4 at 45° C. After the patterned test piece was dipped for 90 seconds, the measured etching performance results are shown in Table 1 below. The unit in Table 1 is % by weight.

[0043] Classification

[0044] It can be seen from Table 1 that, compared with Comparative Examples 1-4, the descum removal efficiency of the etching compositions in Examples 1-4 produced by the present invention is better.

Embodiment 5~13

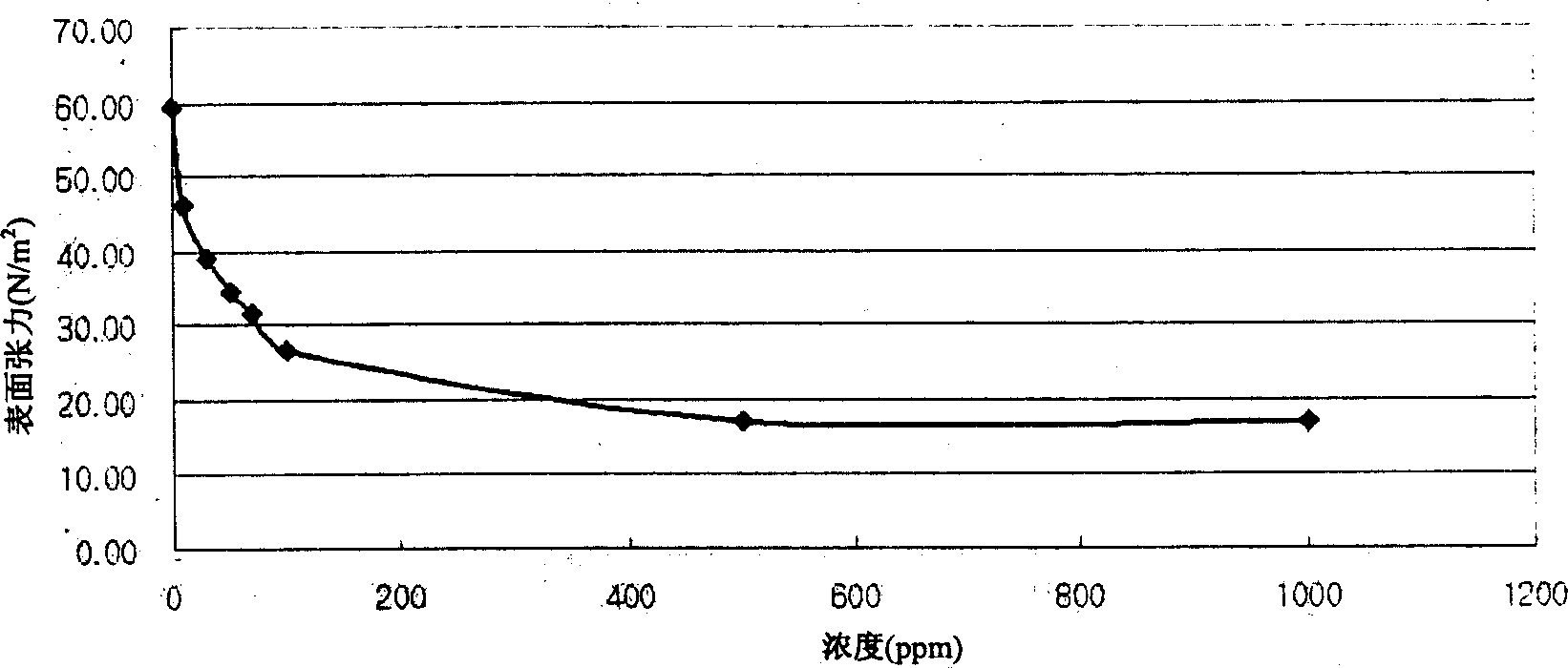

[0046] As shown in Table 2 below, when 15% by mass of hydrochloric acid, 5% by mass of acetic acid, and 1.0% by mass of NH 4 NO 3 In the etching composition composed of the remaining amount of ultrapure water, ammonium perfluorooctane sulfonate is used as a fluorine-based anionic surfactant, and 0ppm, 50ppm, 100ppm, 300ppm, 500ppm, and 1000ppm are added respectively, and uniformly mixed to form an etching composition thing. The unit in Table 2 is % by weight.

[0047] Classification

Example

5

6

7

8

9

10

11

12

13

hydrochloric acid

15

15

15

15

15

15

15

15

15

5

5

5

5

5

5

5

5

5

Additives (NH 4 NO 3 )

1

1

1

1

1

1

1

1

1

Surfactant

0ppm

10ppm

30ppm

50ppm

70ppm

100ppm

300ppm

500ppm

1000ppm

Ultra-pure water

Add to 100% by mass

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com