High temperature decomposition/chemical combination combustion method and apparatus for sewage treatment

A technology of pyrolysis and combustion equipment, which is applied in the direction of combustion methods, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of chlorine secondary pollution, large floor area, high treatment cost, etc., and achieve reduction in construction scale, Reduce investment costs and operating costs, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

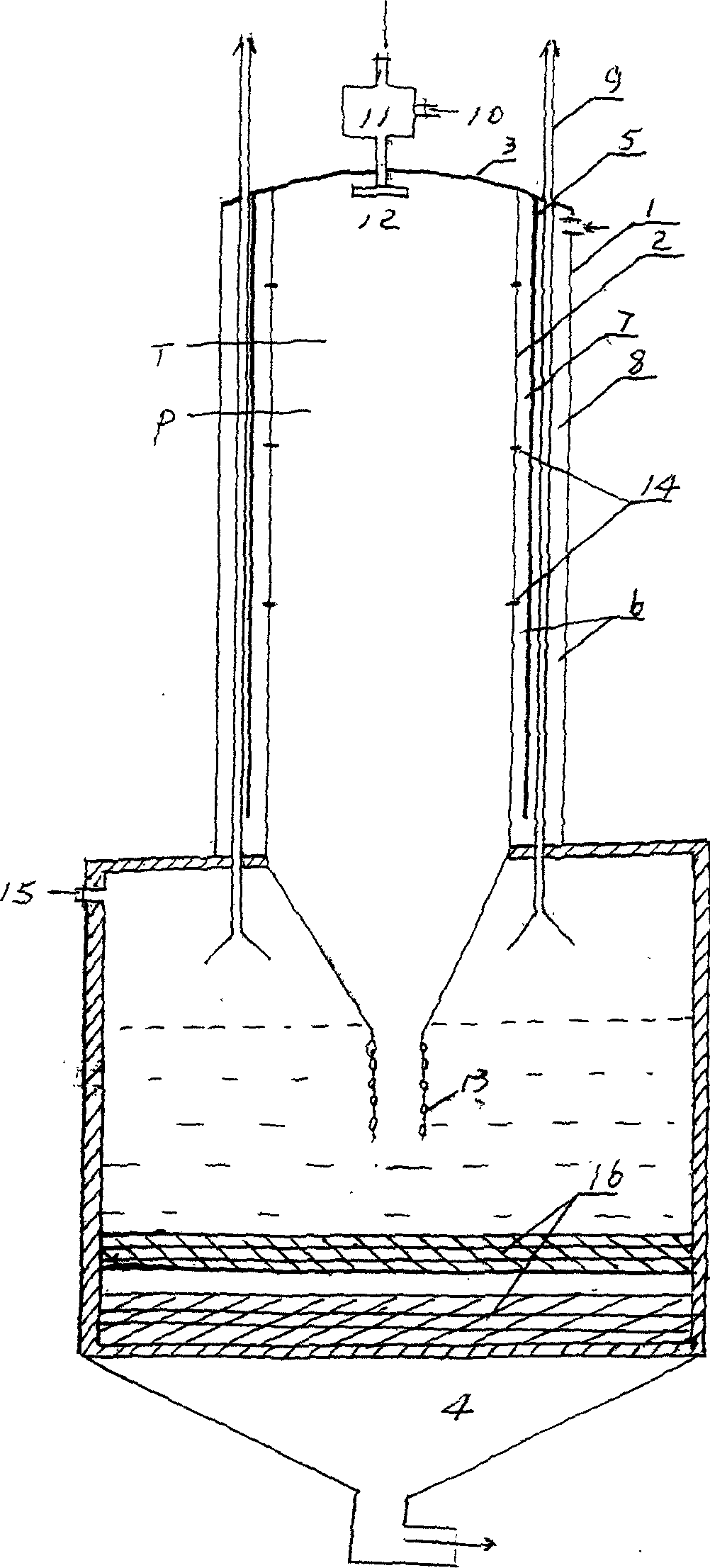

[0031] The method and equipment for treating sewage by pyrolysis / combination combustion provided by the present invention include an outer cylinder 1 and an inner cylinder 2, and a sewage inner cavity 6 between the inner cylinder and the outer cylinder is separated by the cylinder. The plate 5 is divided into two chambers 7 and 8 communicating with each other. The difference between the outer diameter of the inner cylinder and the inner diameter of the outer cylinder is 8 centimeters. meters, and a cylinder with a diameter of 100 centimeters. The central fuel inlet of the dome 3 of the inner and outer cylinders is 5 centimeters in diameter, and the mixer 11 arranged above the fuel inlet is a commercially available general-purpose mixer, and the liquefied gas and air entering the mixer are first calculated by combustion chemical heat balance The amount, but generally adopt the stoichiometric air of about 1.2-1.3 times excess air.

[0032] First, the above-mentioned predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com