Adhesive composition, adhesive sheets and surface protecting film

A technology of adhesive and composition, which is applied in the fields of adhesive optical components and surface protection films, can solve the problems of lower productivity, higher cost, higher cost, etc., and achieve high antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

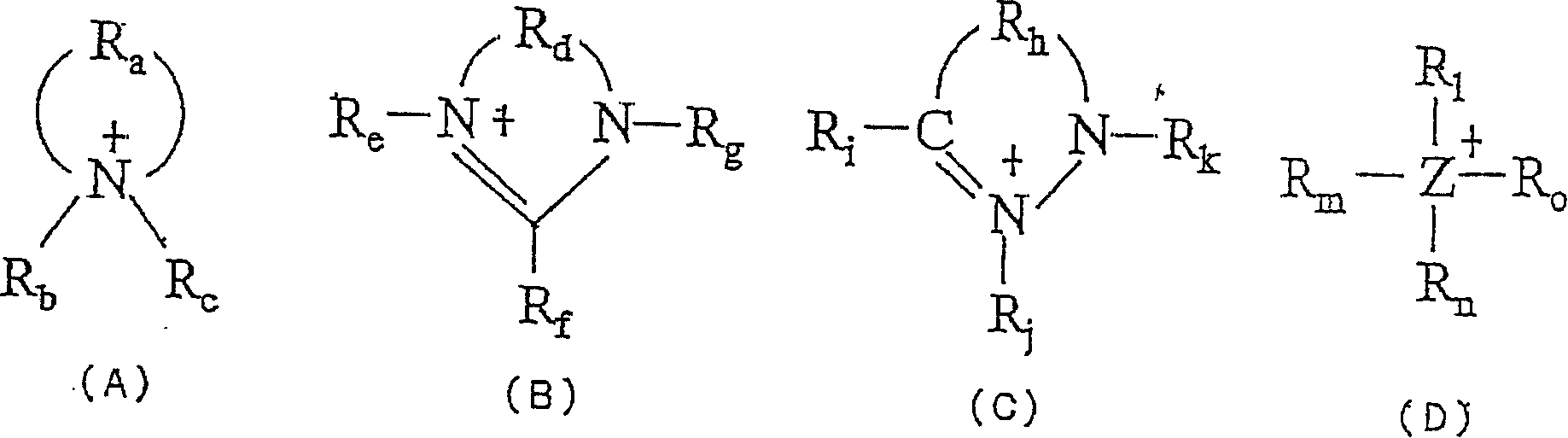

Method used

Image

Examples

Embodiment

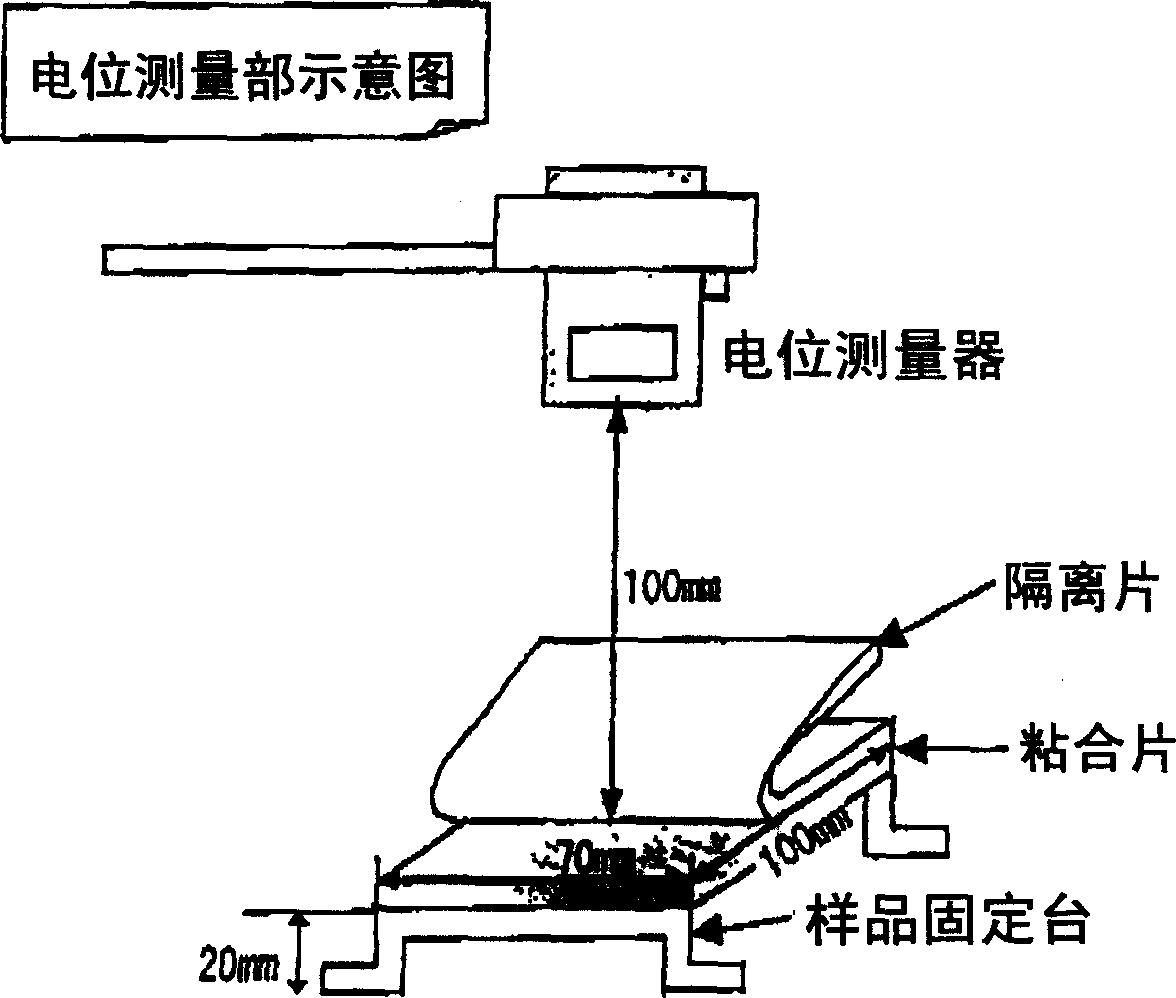

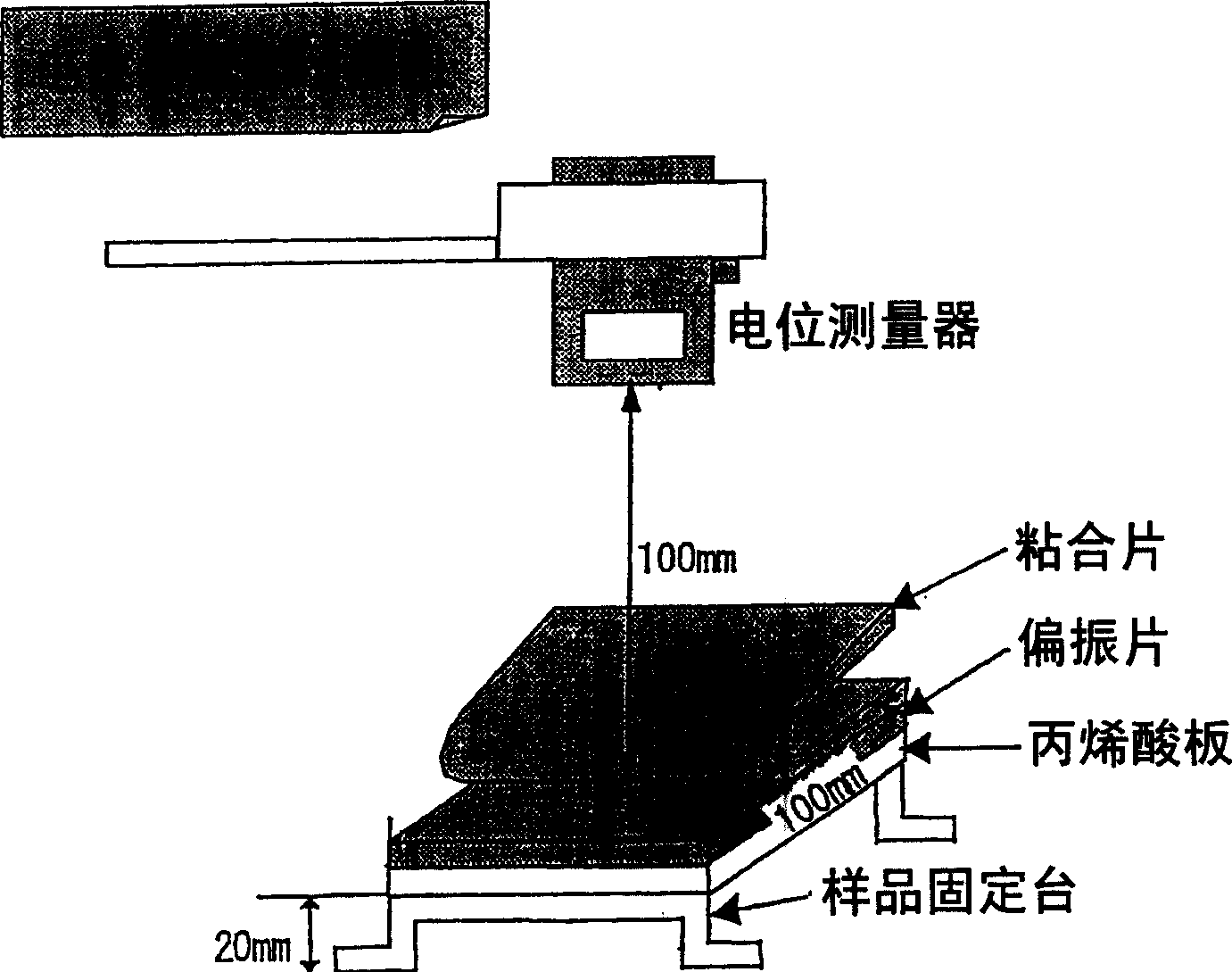

[0260] Next, examples and the like which specifically show the configuration and effects of the present invention will be described. However, the evaluation items in Examples and the like were measured by the methods shown below.

[0261]

[0262] The acid value was measured using an automatic titration device (manufactured by Hiranuma Sangyo Co., Ltd., COM-550), and was obtained by the following formula.

[0263] A={(Y-X)×f×5.611} / M

[0264] A: acid value

[0265] Y: Titration of sample solution (ml)

[0266] X: Titration of the solution of 50g of mixed solvent only (ml)

[0267] f: factor of the titration solution

[0268] M: weight of polymer sample (g)

[0269] The measurement conditions are as follows.

[0270] Sample solution: about 0.5 g of a polymer sample was dissolved in 50 g of a mixed solvent (toluene / 2-propanol / distilled water=50 / 49.5 / 0.5, weight ratio) to prepare a sample solution.

[0271] Titration solution: 0.1N, 2-propanol potassium hydroxide solutio...

manufacture example I-1

[0324] (acrylic polymer A)

[0325] In a nitrogen stream at 65°C, react a mixture of 200 g of 2-ethylhexyl acrylate, 8 g of 2-hydroxyethyl acrylate, 0.4 g of 2,2'-azobisisobutyronitrile, and 312 g of ethyl acetate. A solution (40% by weight) of an acrylic polymer having a Tg=-68° C., a weight average molecular weight of 500,000, and an acid value of 0 was obtained.

manufacture example I-2

[0327] (acrylic polymer B)

[0328] In a nitrogen stream at 65°C, react a mixture of 200 g of n-butyl acrylate, 8 g of 2-hydroxyethyl acrylate, 0.4 g of 2,2'-azobisisobutyronitrile, and 625 g of ethyl acetate for 6 hours to obtain A solution (25% by weight) of an acrylic polymer having Tg=-54°C, a weight average molecular weight of 540,000, and an acid value of 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com