Method for preparing organic silicon high-temperature-resistant adhesive by removing micro-water from methylcyclosiloxane used as raw materials and device therefor

A technology of methyl ring body and high temperature glue, applied in the direction of organic decomposition, chemical instruments and methods, etc., can solve problems such as unsatisfactory dehydration effect and appearance of clear water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

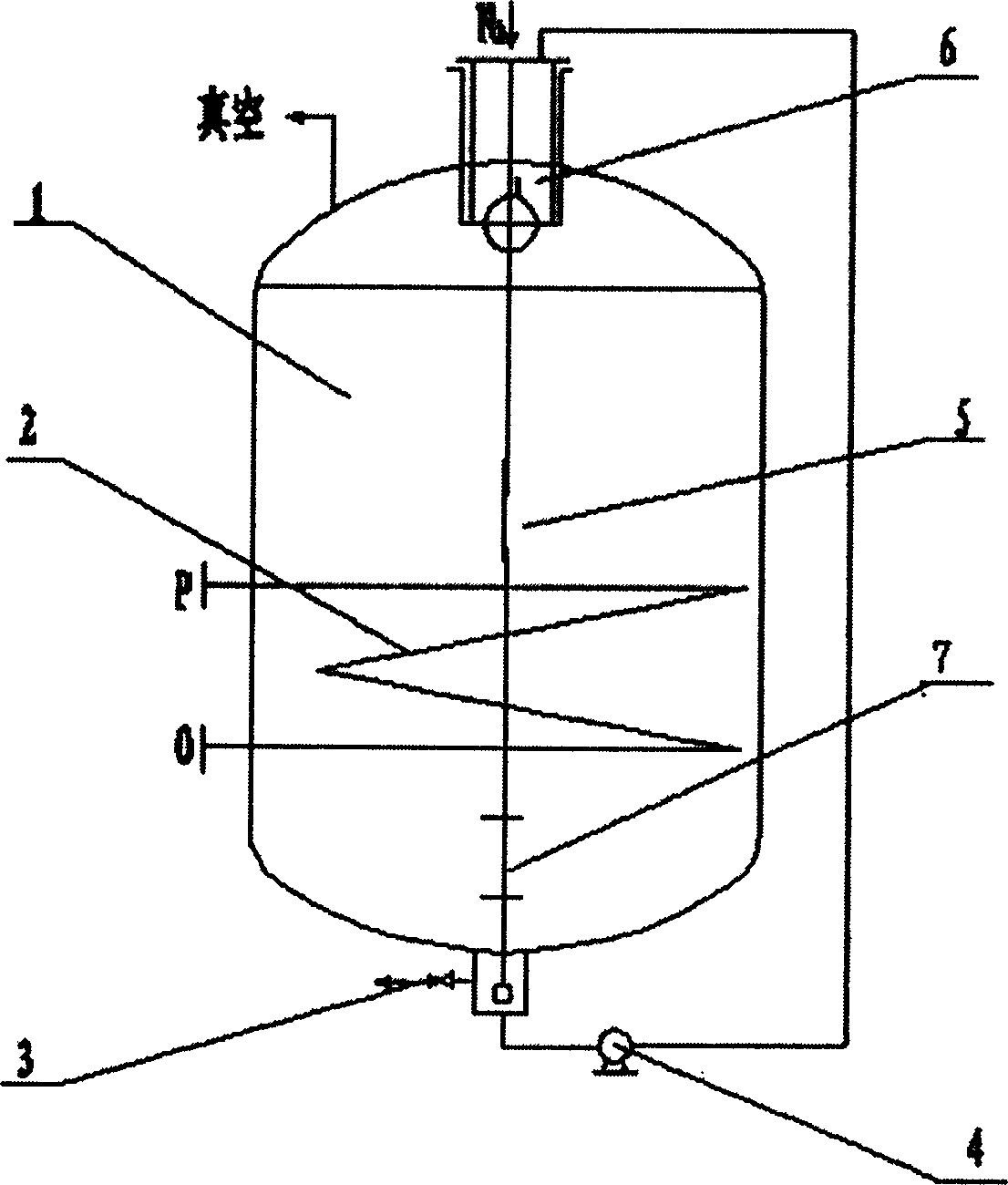

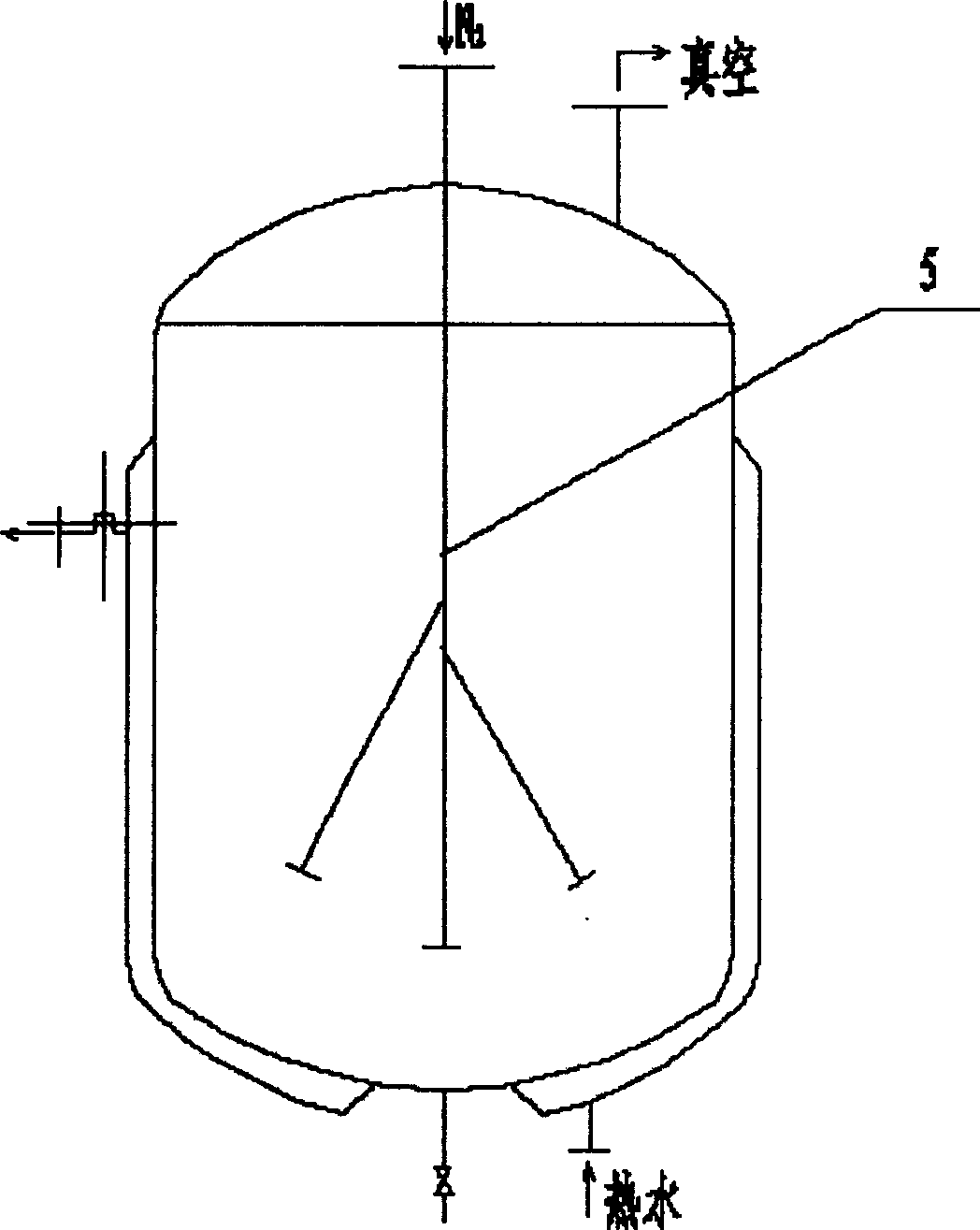

[0017] Add 680kg of mixed methylcyclosiloxane and vinyl rings to a 1000L dehydration kettle after being metered by a metering tank. After bubbling with nitrogen, start the circulation pump to circulate, and open the coil steam valve of the dehydration kettle. , put in steam to heat, control the material temperature at 66°C, vacuum spray and dehydrate for 3 hours, test the water content in the ring body at 8ppm, add 4.5 / 10,000 alkali glue catalyst and 2.45 kg of vinyl head sealant, and carry out The molecular weight of raw rubber obtained by polymerization is 660,000, and the volatile content is 1.0%.

Embodiment 2

[0019] Add 560 kg of methylcyclosiloxane and vinyl ring to the 1000L dehydration kettle through the metering tank, blow nitrogen into it, start the circulating material pump, spray the material circularly, and open the disc of the dehydration kettle. Heat up the tube steam valve, control the temperature of the material at 68°C, vacuum spray and dehydrate for 3 hours, test the moisture content in the ring body at 7.5PPm, and then add 4.5 / 100,000 alkali glue and 2.1 kg of vinyl head sealant , to carry out polymerization to obtain raw rubber with a molecular weight of 670,000 and a volatile content of 1.1%.

Embodiment 3

[0021] Add 1080kg of methylcyclosiloxane and vinyl ring to a 1300L dehydration kettle after being metered by a metering tank, blow nitrogen into the tank, start the circulation pump for special circulation spraying, turn on the coil to raise the temperature of the steam, and control the material The temperature is 67°C, vacuum spray dehydration for 3 hours, the water content in the test ring is 9PPm, add 4.5 / 100,000 alkali glue and 6 kg of methyl capping agent, the molecular weight of the polymerized raw rubber is 650,000, volatilization Parts 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com