Method for preparing nanometer tungsten carbide powder by methyl alcohol cracking

A methanol cracking, nano-technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of inability to prepare ultra-fine particle WC powder, violent oxidation or explosion, powder fouling, etc., to achieve low cost and high cost. Selective, uniform and stable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

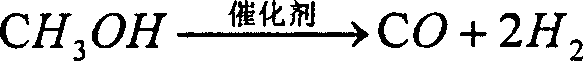

[0019] With an average particle size of 21nm and a specific surface area (BET) of 54m 2 / g WO 3 Powder as raw material. Methanol (CH 3 OH) to the preheating pipeline, keep the preheating temperature at 320°C, methanol is vaporized, and sent to the catalytic cracker, the working temperature is 540°C, methanol is cracked into CO and H 2 , CO and H 2 It is dehydrated by a dryer and molecular sieve, and sent to a tube reactor after drying. The gas flow rate is 200ml / min. Nano WO 3 The loading amount of the powder is 12g / boat, it is kept at 510° C. for 3.5 hours, and it is taken out after fully cooling to obtain nanometer WC powder.

Embodiment 2

[0021] With an average particle size of 21nm and a specific surface area (BET) of 54m 2 / g WO 3 Powder as raw material. Liquid pump transports methanol (CH 3 OH) to the preheating pipeline, methanol is vaporized after preheating at 380°C, and sent to a catalytic cracker, where methanol is cracked into CO and H at 490°C 2 , the cleavage products CO and H 2 After being dehydrated by a dryer and molecular sieve, it is sent to a tubular reactor, and the gas flow rate is controlled at 350ml / min. Nano WO 3 The loading amount of the powder is 25g / boat, and it is kept at 720° C. for 2.5 hours to obtain nanometer WC powder.

Embodiment 3

[0023] With an average particle size of 21nm and a specific surface area (BET) of 54m 2 / g WO 3 Powder as raw material. Methanol (CH 3 OH) to the preheating pipeline, keep the preheating temperature at 410°C, methanol is vaporized, and sent to the catalytic cracker, the working temperature is 430°C, methanol is cracked into CO and H 2 , CO and H 2 It is dehydrated by a dryer and molecular sieve, and sent to a tube reactor after drying. The gas flow rate is controlled at 550ml / min. Nano WO 3 The loading amount of the powder is 33g / boat, and it is incubated at 940° C. for 1.5 hours to obtain nanometer WC powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com