Method for reducing loaded metal catalyst using low temperature plasma

A low-temperature plasma, metal-loaded technology, used in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as unsuitable industrial applications, achieve strong reduction performance, simple process, and avoid adverse thermal effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

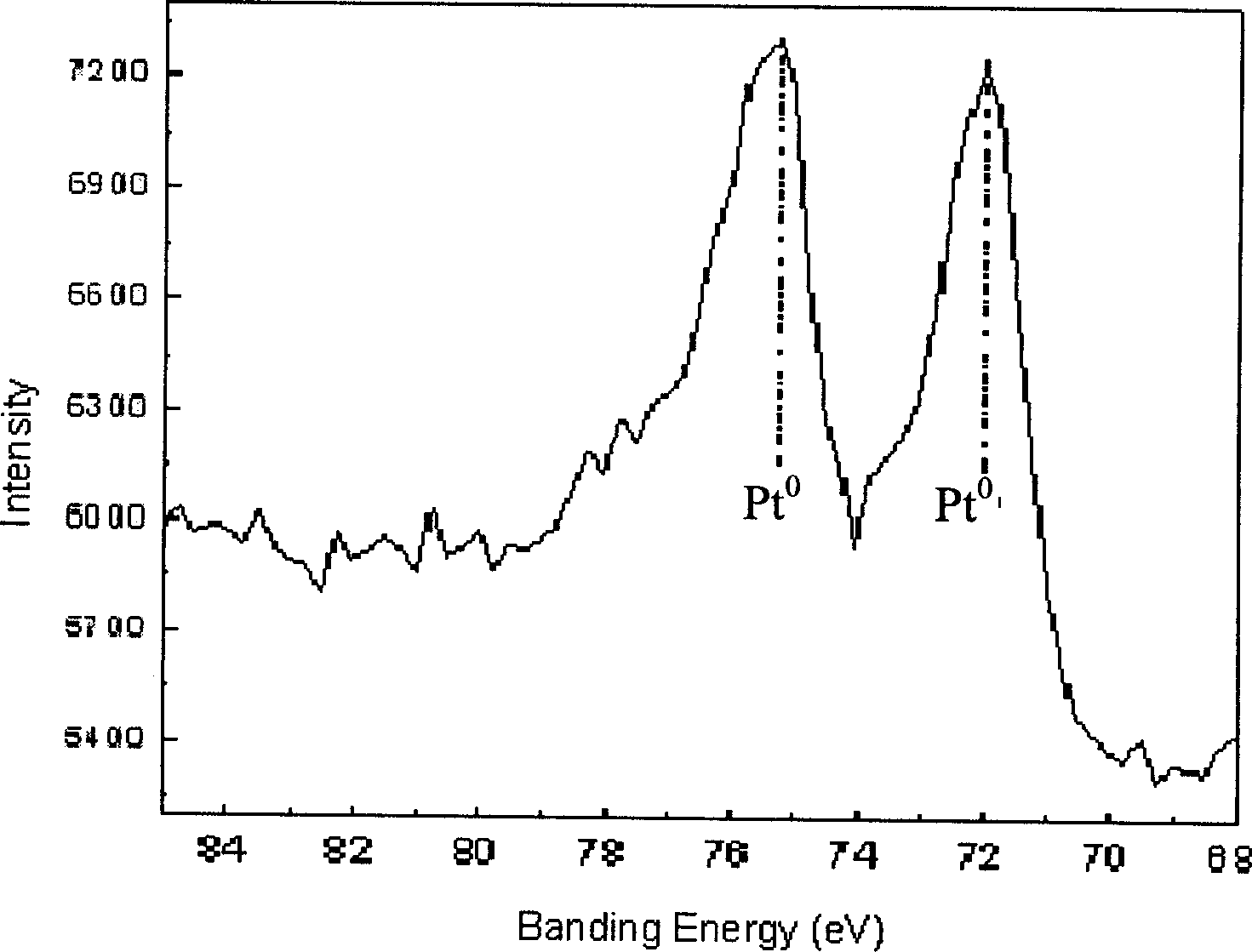

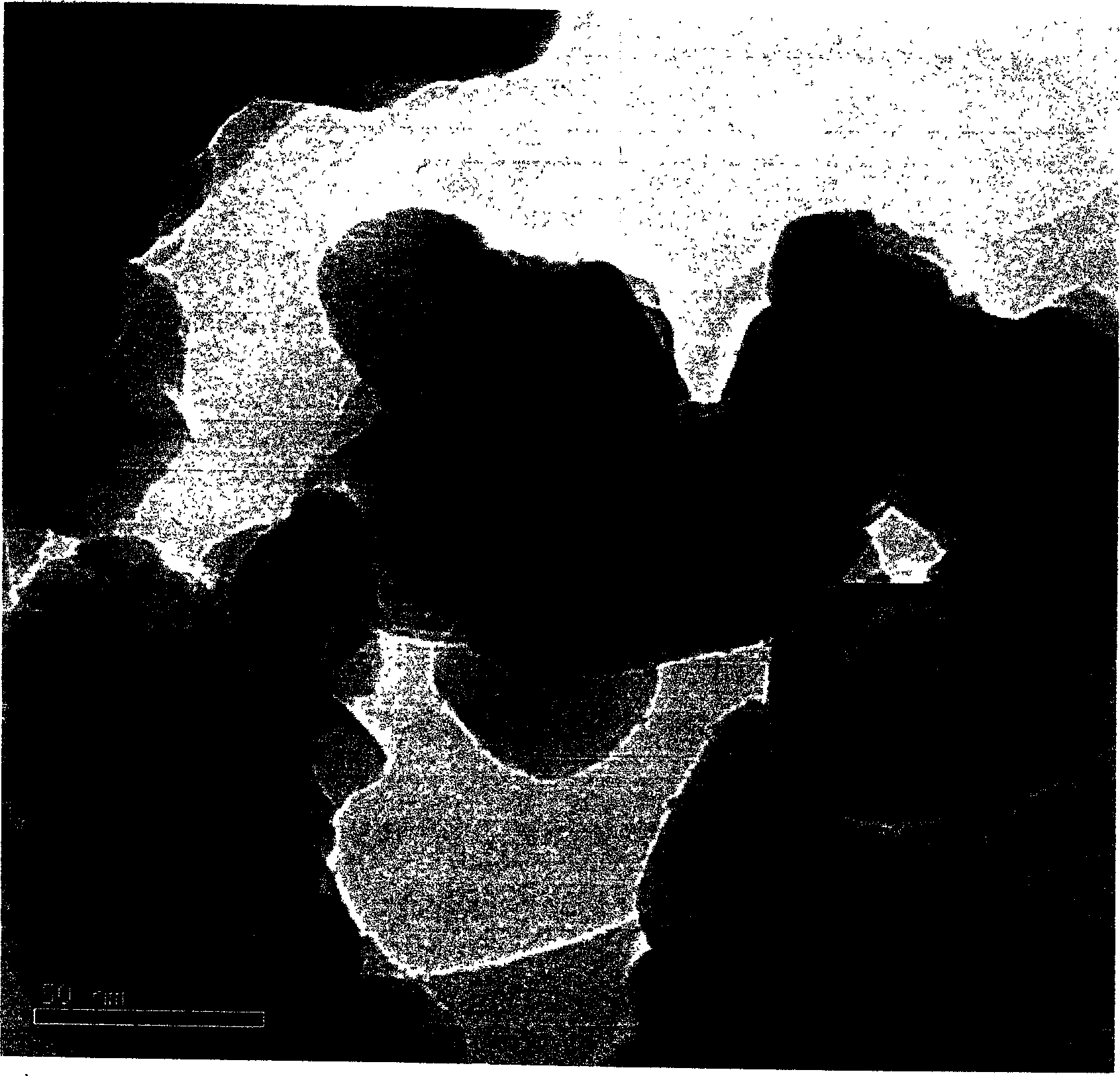

[0021] with TiO 2 as a carrier, impregnated with H 2 PtCl 6 solution, the content of metal Pt is 0.5%; stand for 24 hours, and dry at 100°C for 4 hours; the catalyst is reduced by corona discharge plasma, the catalyst is placed between the two plate electrodes of the discharge tube, airtight, the system is evacuated, and the Enter Ar as the discharge gas, maintain the pressure of 200Pa, apply a DC voltage of 1000V on the electrode, and the reduction time is 30 minutes.

Embodiment 2

[0023] Basically the same as Example 1, but La 2 o 3 As a carrier, impregnated with Ni(NO 3 ) 2 solution, the content of metal Ni is 7.0%; N 2 As discharge gas, the pressure is 50Pa, the voltage is 500V DC, and the reduction time is 45 minutes; then impregnate Fe(NO 3 ) 3 Solution, the content of the second metal Fe is 3.0%, repeat the previous treatment steps.

Embodiment 3

[0025] It is basically the same as Example 1, but gac is the carrier, PdCl 2 Dissolve in hydrochloric acid solution, then evaporate the solution until nearly dry, then add deionized water to form a solution, and then impregnate, the content of metal Pd is 20.0%; He is used as discharge gas, the pressure is 1000Pa, the voltage is 5000V DC, and the reduction time is 120 minutes .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com