Double-face sound-absorbing contacting oral cavity sound shield without cotton

A sound barrier and cavity technology, applied in noise absorption devices, buildings, etc., can solve the problems of difficulty in meeting traffic noise frequency requirements, small sound absorption frequency band width, etc., to reduce thickness, widen sound absorption frequency band, and long life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

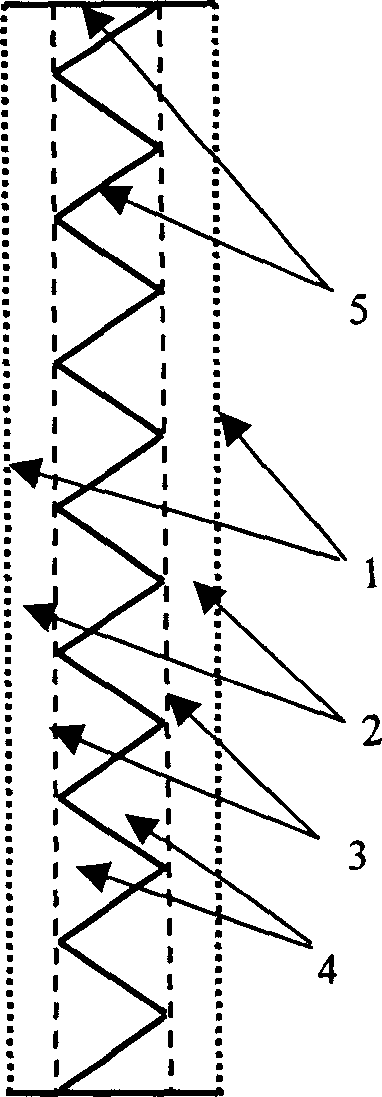

[0013] Such as Figure 1~3 As shown, the present invention includes: two layers of aluminum fiber sheets 1, two layers of cavities 2, two layers of micro-perforated plates 3, toothed cavities 4, folded partitions 5, and surrounding frames 6. The sound-absorbing surfaces on both sides of the sound barrier are aluminum fiber sheets 1, two layers of cavities 2 are between the two layers of aluminum fiber sheets 1 and two layers of micro-perforated plates 3, and the spaces between the micro-perforated plates 3 and the folded partition 5 are The tooth-shaped cavity 4 and the surrounding frame 6 fix the positions of the aluminum fiber thin plate 1 , the micro-perforated plate 3 and the folding partition 5 .

[0014] The sound-absorbing surfaces on both sides of the sound barrier, that is, the two outer surfaces of the sound barrier, are all aluminum fiber sheets. The aluminum fiber sheet 1 and the cavity 2 constitute the first group of sound-absorbing structures, and the micro-perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com