Supercritical carbon dioxide mugwort active substance extracting method

A carbon dioxide and supercritical technology, applied in the field of extraction and separation technology, achieves the effects of reducing energy consumption, high efficiency, and safe and reliable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

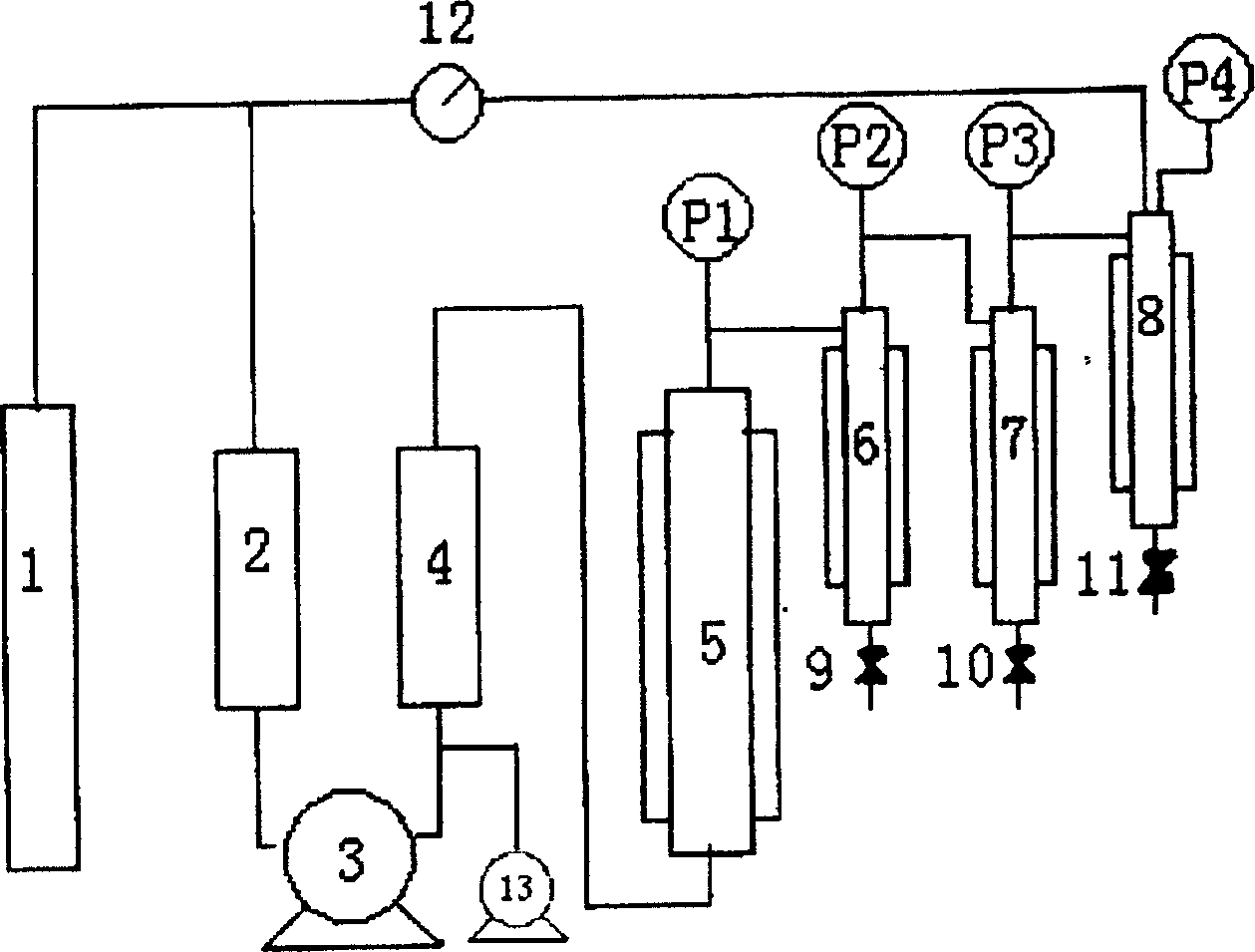

[0024]Example 1: Put 1 kg of mugwort leaf fragments that were dried with hot air and chopped into 3 mm into an extraction tank, and carry out supercritical carbon dioxide extraction under the conditions of a pressure of 16 MPa and a temperature of 45° C. Adjust the pressure of the primary separation tank to 7MPa, the temperature is 45°C, the pressure of the secondary separation tank is 5MPa, the temperature is 50°C, the flow rate of carbon dioxide is 30kg / h, and after 4 hours of extraction, 25.6 mugwort leaf oil can be obtained from the primary separation tank g, 2.7g of Artemisia argyi oil mixture was obtained in the secondary separation tank, and the total yield was 2.83%.

Embodiment 2

[0025] Example 2: Put 1 kg of mugwort leaf fragments dried in the shade and chopped into 1 mm into an extraction tank, and carry out supercritical carbon dioxide extraction at a pressure of 25 MPa and a temperature of 35° C. Adjust the pressure of the first-stage separation tank to 10MPa, the temperature to 40°C, the pressure of the second-stage separation tank to 6MPa, the temperature to 50°C, the pressure of the third-stage separation tank to 4MPa, the temperature to 50°C, and the flow rate of carbon dioxide to 15kg / h, after 2 hours For the extraction, 17.2 g of the mugwort leaf oil can be obtained from the first-stage separation tank, 2.9 g of the mugwort leaf oil mixture can be obtained from the second-stage separation tank, and 0.6 g of the mugwort leaf oil mixture can be obtained from the third-stage separation tank, with a total yield of 2.07%.

Embodiment 3

[0026] Embodiment 3: put 1kg into the extracting tank through drying, pulverizing into 0.5mm mugwort leaf velvet, carry out supercritical carbon dioxide extraction under the condition that the pressure is 20Mpa and the temperature is 40°C, and the extraction entrainer adopts 95% ethanol 100g. Adjust the pressure of the primary separation tank to 8MPa, the temperature to 45°C, the pressure of the secondary separation tank to 5MPa, the temperature to 50°C, and the flow rate of carbon dioxide to 10kg / h. After 1 hour of extraction, Artemisia argyi oil 23.9 can be obtained from the primary separation tank g, 2.5g of Artemisia argyi oil mixture was obtained in the secondary separation tank, and the total yield was 2.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com