Cylinder non-contact ultrasound electric machine

An ultrasonic motor, non-contact technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve complex structure, service life and operating speed limitations, high cost, etc. problem, to achieve the effect of high speed and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

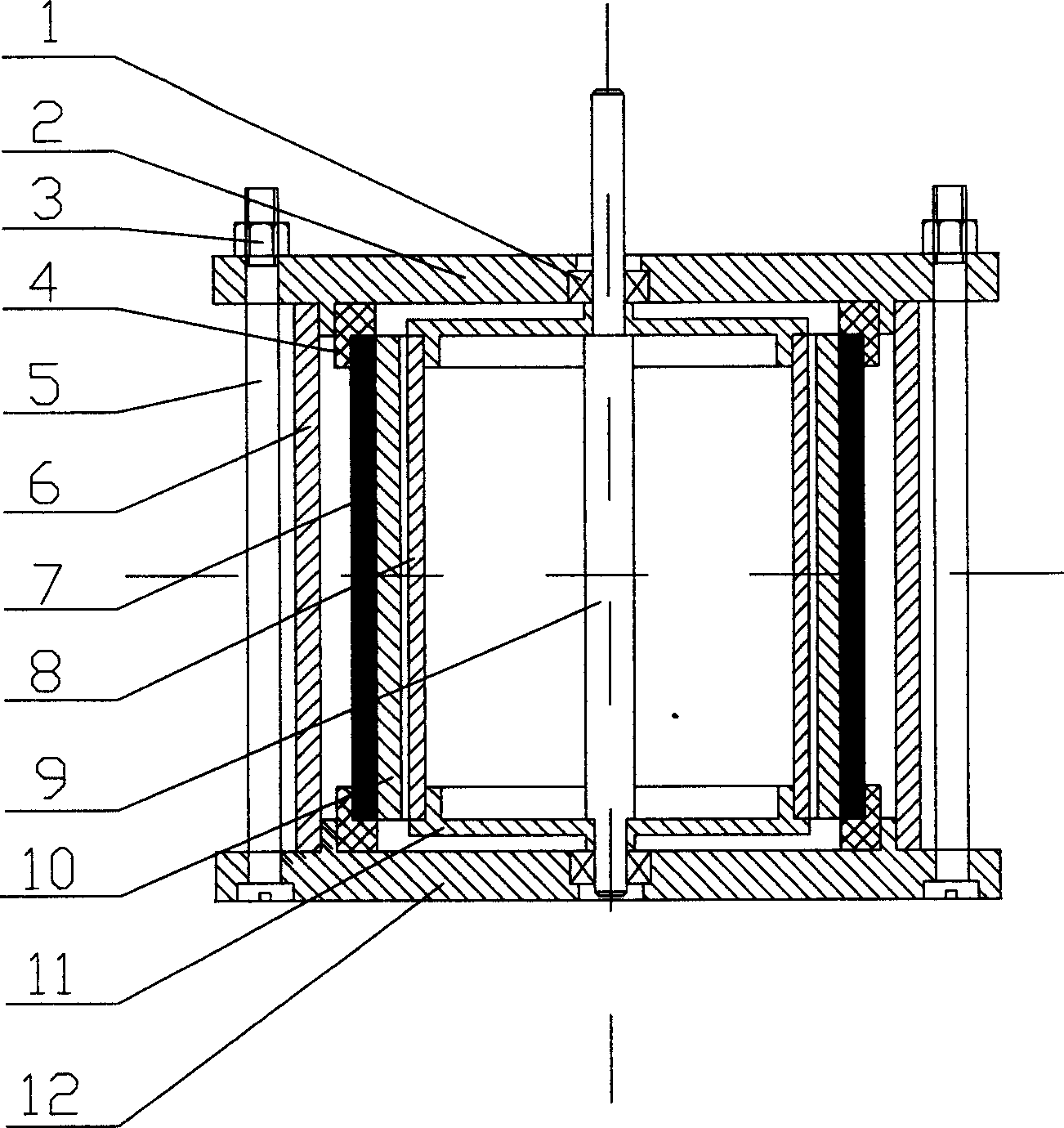

[0008] The invention is a novel ultrasonic motor developed based on the use of piezoelectric ceramic sheets to excite B(0,3) mode acoustic radiation pressure and acoustic viscous stress of a cylindrical stator.

[0009] It mainly consists of a stator assembly, a rotor assembly and a bracket assembly. figure 1 It is a schematic diagram of the specific structure of the present invention. It can be seen from the figure that the stator assembly of the motor is composed of a stator base 10 and four pieces of piezoelectric ceramics 7 pasted in four evenly distributed rectangular grooves on the outer surface of the stator base, and placed on the base 12 and The gasket 4 in the cover plate 2 is transition fit; the rotor base 8 of the rotor assembly with a certain gap between the stator assembly and the stator assembly is installed on the output shaft 9 through the bushing 11, and the output shaft 9 is installed on the cover plate 2 and the cover plate 2 through a pair of bearings 1. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com