Automatic flushing device for oil field working equipment

An operation equipment and automatic cleaning technology, which is applied to cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems that affect safe operations, reduce the strength of the derrick, and cannot realize remote control of pressure adjustment, etc., to achieve Improve the efficiency of cleaning work and ensure the effect of smooth implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

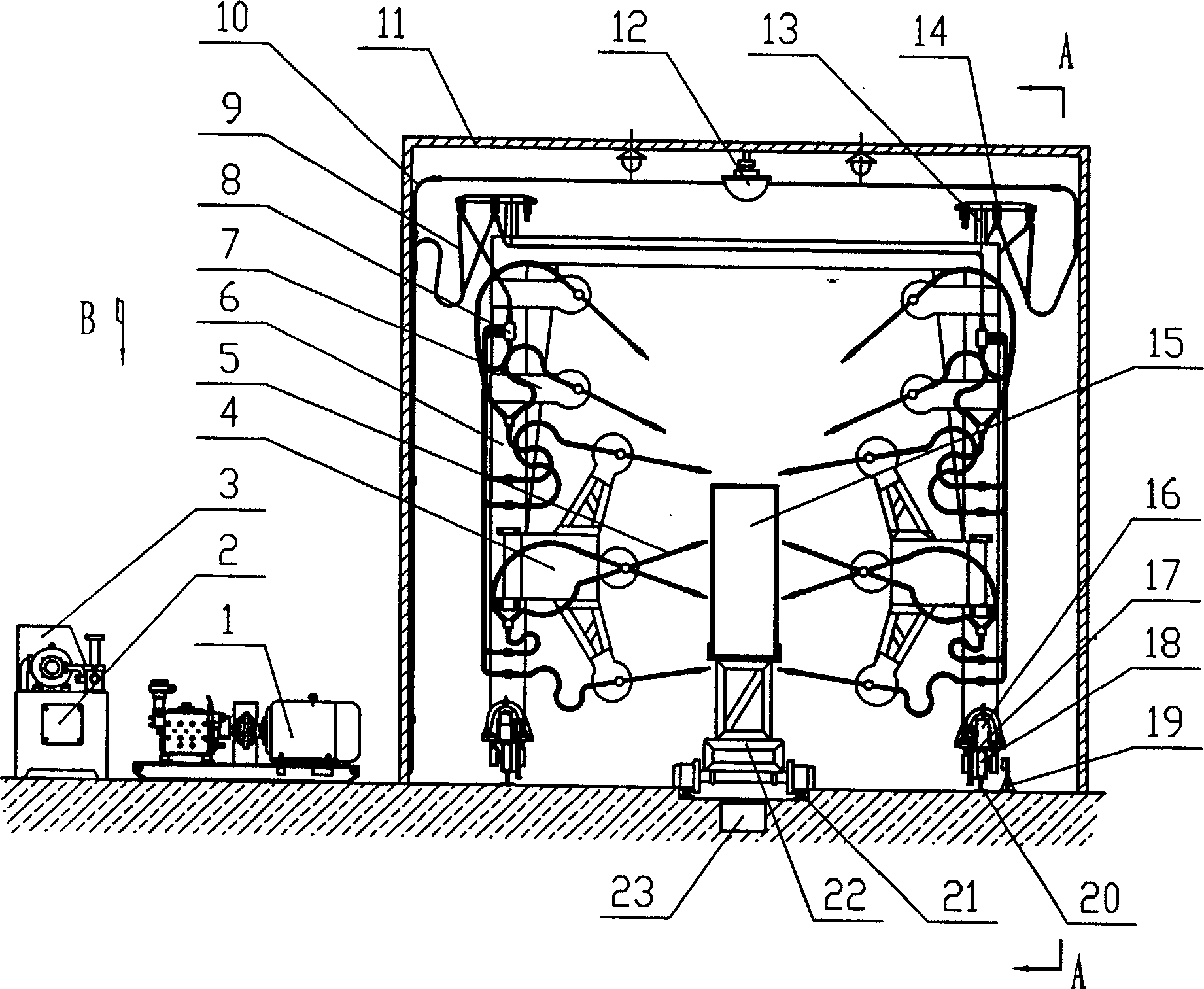

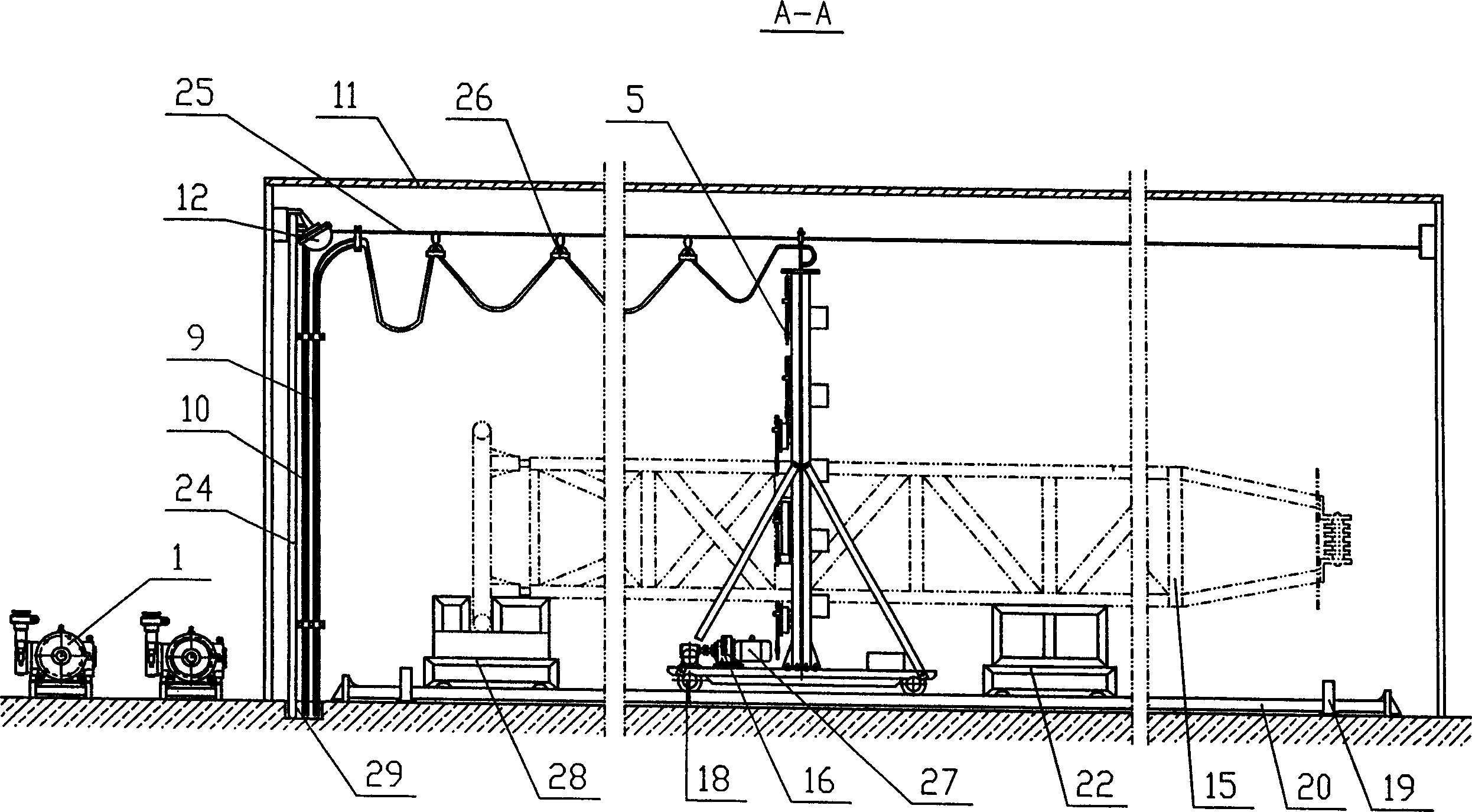

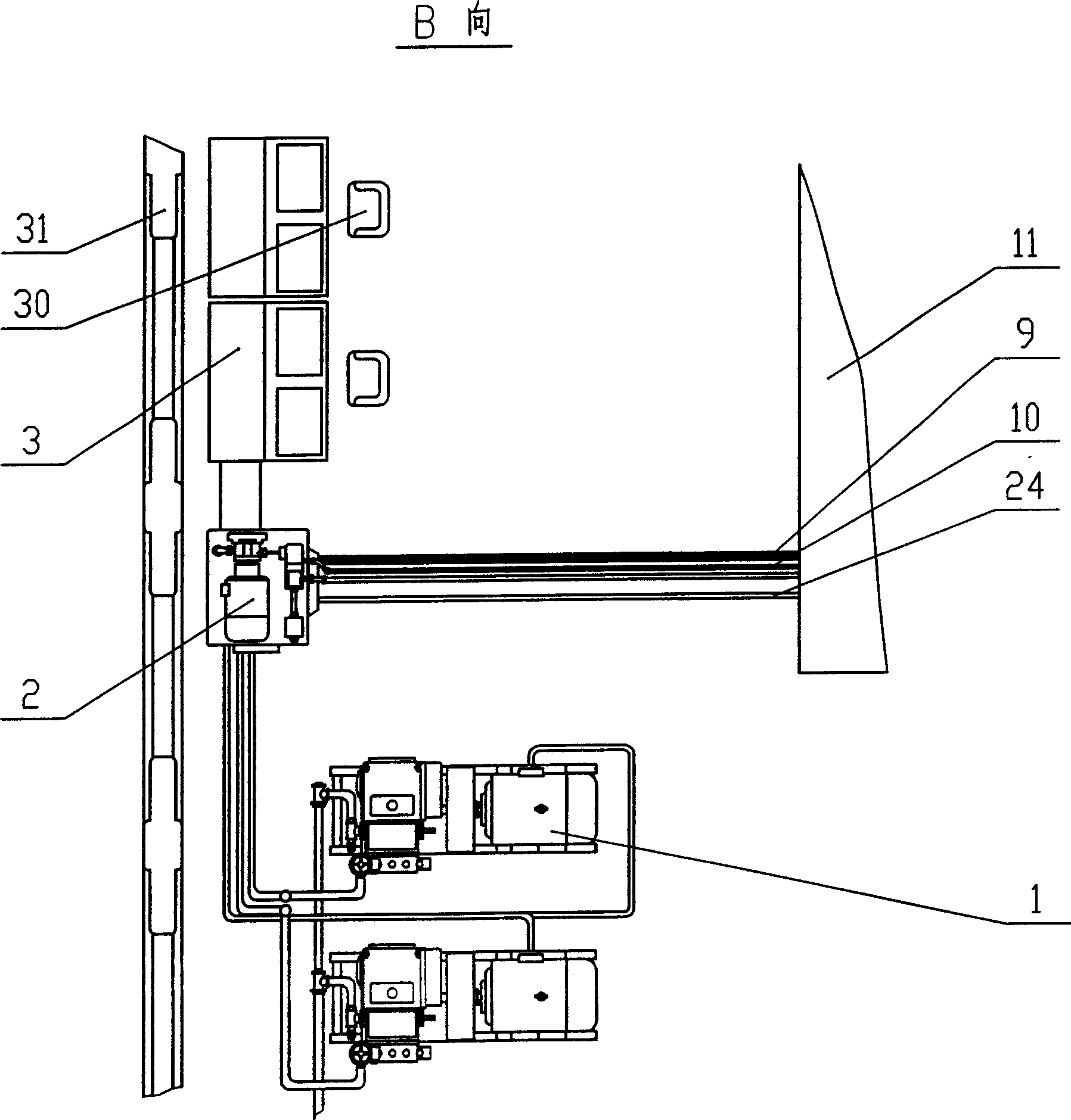

[0021] according to Figure 1-5 Describe in detail the specific structure and working process of the present invention: the device includes a door-type walking frame 6, an assembled fixed adjustment manipulator 7 and a movable adjustment manipulator 4, a high-pressure cleaning spray bar 5 with a spray head, a high-pressure cleaning machine connected to the spray head Water jet cleaning machine 1 and its automatic control system, etc.

[0022] Wherein the specifications and models of the portal type walking frame 6 should be determined according to actual use requirements. The rollers 18 running along the rails 20 on both sides of the frame 6 are respectively driven by the transmission device 16 driven by the motor 27, and the operation of the motor is controlled by an automatic control system. Because the two sides of frame 6 adopt the automatic control drive mode that utilizes motor 27 to drive transmission device 16 respectively, frame 6 can automatically bidirectional walk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com