Sticker pressure foot and sewing machine with same

A technology of sticking strips and presser feet, which is applied in the field of sewing machines, can solve the problems of small application range and achieve the effect of convenient adjustment and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

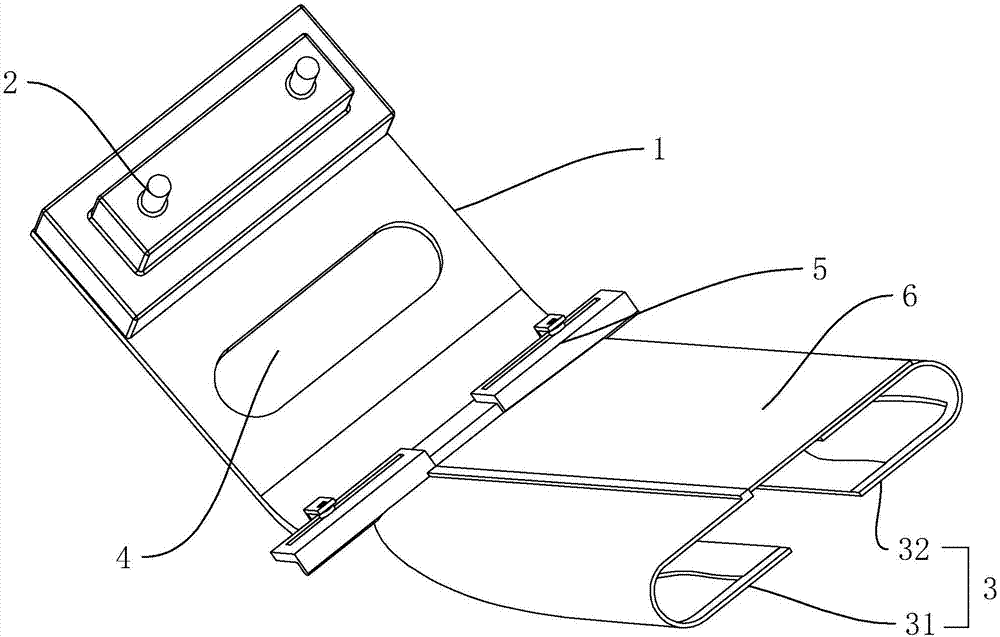

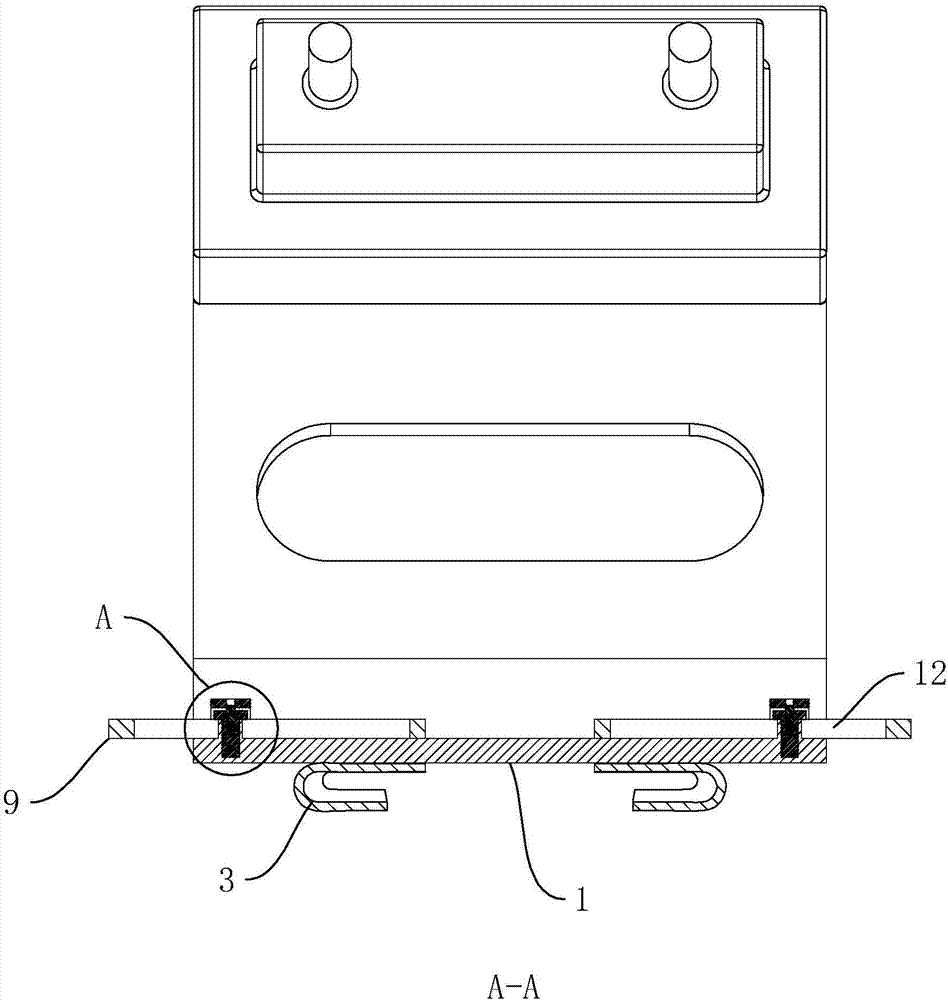

[0038] Example 1: A sticking presser foot, such as figure 1 As shown, it includes a pressing plate with a needle hole 1, a pressing rod 2 and a pulling cylinder 3 arranged on the pressing plate 1. The pressing rod 2 is used to fix the sewing machine to each other, and the pulling cylinder 3 includes a left half 31 and a right half 32 , The left half 31 and the right half 32 are slidably connected to the pressure plate 1 away from or close to each other. The pressure plate 1 is provided with a positioning mechanism 5 for positioning the left half 31 and the right half 32. An extension plate 6 is fixed on the outer wall, and the extension plate 6 extends toward the right half body 32 and is attached to the outer wall of the right half body 32.

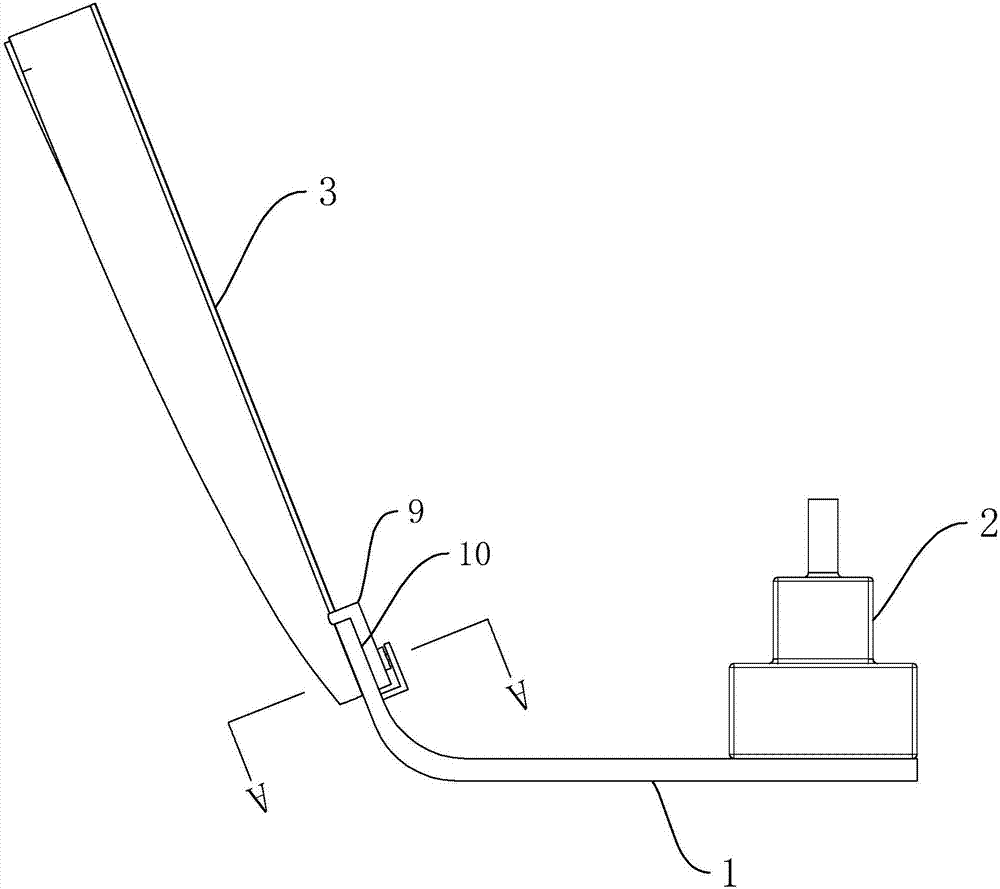

[0039] Such as figure 2 with image 3 As shown, the upper surface of the left half body 31 and the right half body 32 is provided with an "L"-shaped splint 9, and one end of the splint 9 is fixed on the pulling cylinder 3, and a clamp is fo...

Embodiment 2

[0043] Example 2: A sticking foot, such as Image 6 with Figure 7 As shown, the main difference from the first embodiment is that: the pressure plate 1 is provided with a frame 15; the left half 31 and the right half 32 are respectively provided with a slider 14; the frame 15 is provided with a supply slider 14 The sliding groove 13 sliding left and right, the sliding block 14 is slidably arranged in the sliding groove 13; the positioning mechanism 5 includes a double-headed screw 51b and a fixed block 52b. The two ends of the double-headed screw 51b have opposite screw directions, and the fixed block 52b is fixed. On the inner wall of the chute 13, two sliding blocks 14 are respectively located on the left and right sides of the fixed block 52b, the double-headed screw 51b is transversely passed through the fixed block 52b and is rotatably connected with the fixed block 52b. The two ends of the double-headed screw 51b are respectively Passing through the sliders 14 on both sid...

Embodiment 3

[0045] Embodiment 3: A sewing machine, such as Figure 8 As shown, the sticking foot 8 in the first embodiment or the second embodiment is included.

[0046] The same parts are indicated by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top" "Face", "inner" and "outer" respectively refer to directions toward or away from the geometric center of a particular component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com