Partial discharge test oil cup for oil-paper insulation

A technology of partial discharge and oil-paper insulation, applied in the direction of testing dielectric strength, etc., can solve the problems of inconvenient adjustment of distance, influence of test results, and difficult replacement of high-voltage terminal needle electrodes, etc., to achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described with embodiment below in conjunction with accompanying drawing.

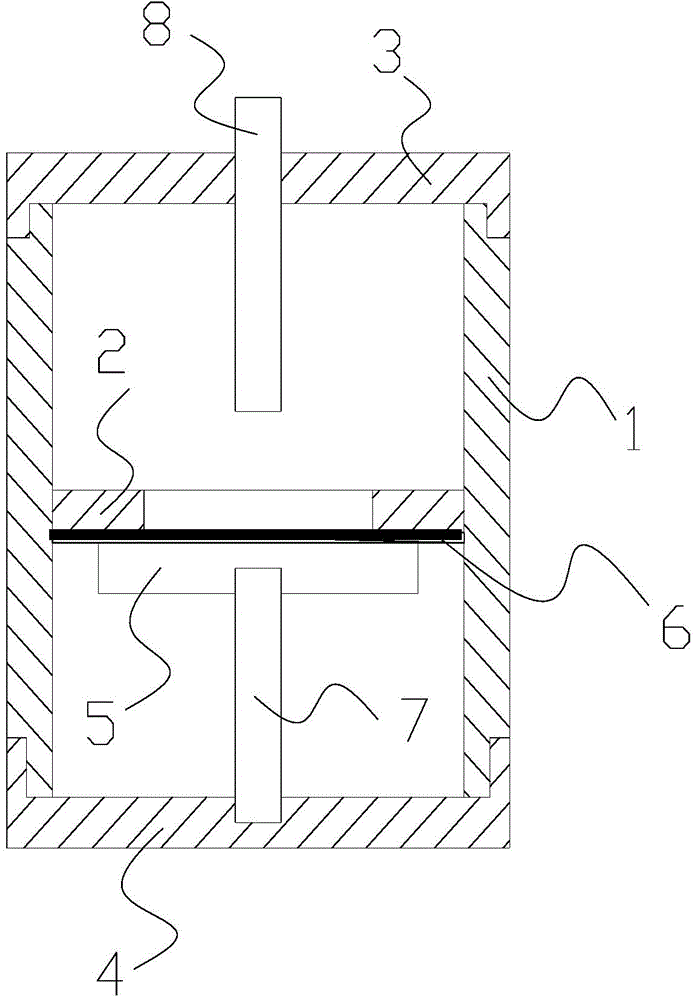

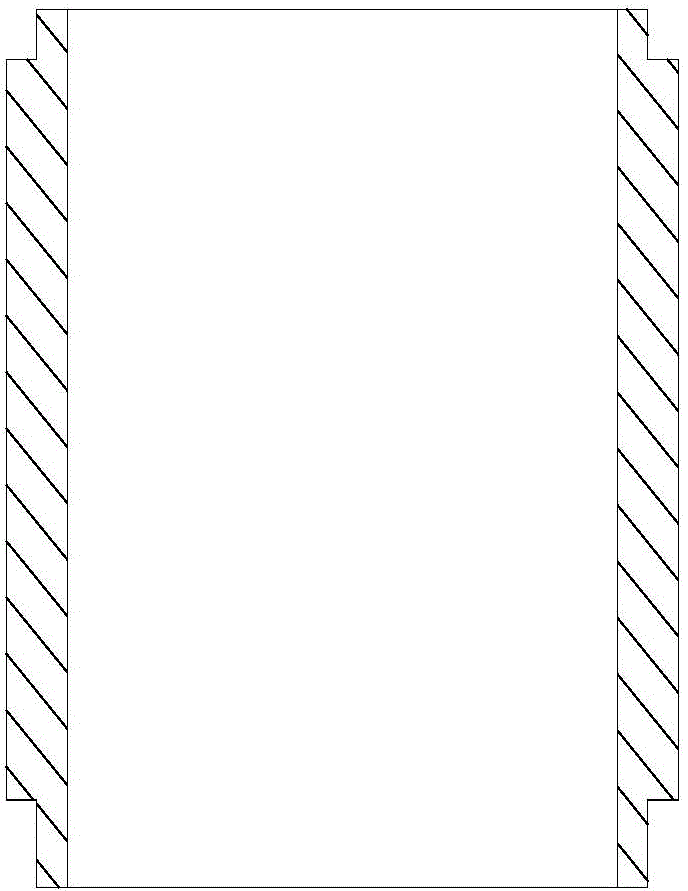

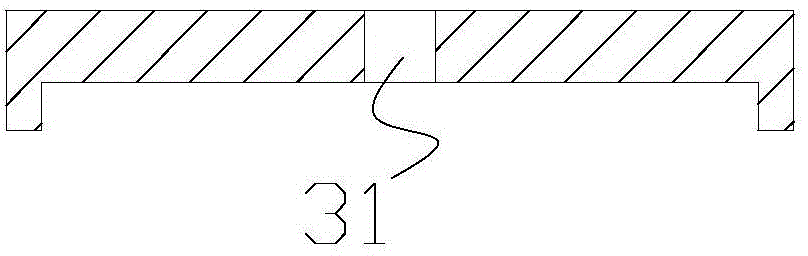

[0026] Such as Figure 1-5 As shown, an oil paper insulation partial discharge test oil cup is characterized in that: it includes a plexiglass tube 1, the inner wall of the plexiglass tube is smooth, and the upper nozzle of the plexiglass tube is provided with a plexiglass upper cover 3, a lower tube The mouth is provided with an aluminum lower cover 4, and a through hole 31 is opened in the middle of the plexiglass upper cover 3, and a first metal guide rod 7 is pierced through the through hole; a counterbore 41 is opened in the middle of the top surface of the aluminum lower cover. , the counterbore is fixed with an upright second metal guide rod 8, and the upper end of the second metal guide rod 8 is inserted into a counterbore on the bottom surface of a brass disc-shaped electrode 5; the first metal guide rod and the brass material An annular plexiglass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com