Method of mild hydrocracking raw material heavy oil

A technology for hydrocracking and heavy raw materials, applied in the field of hydrocarbon oil cracking, can solve the problems of fractional distillation of raw materials, high investment, increased equipment and energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

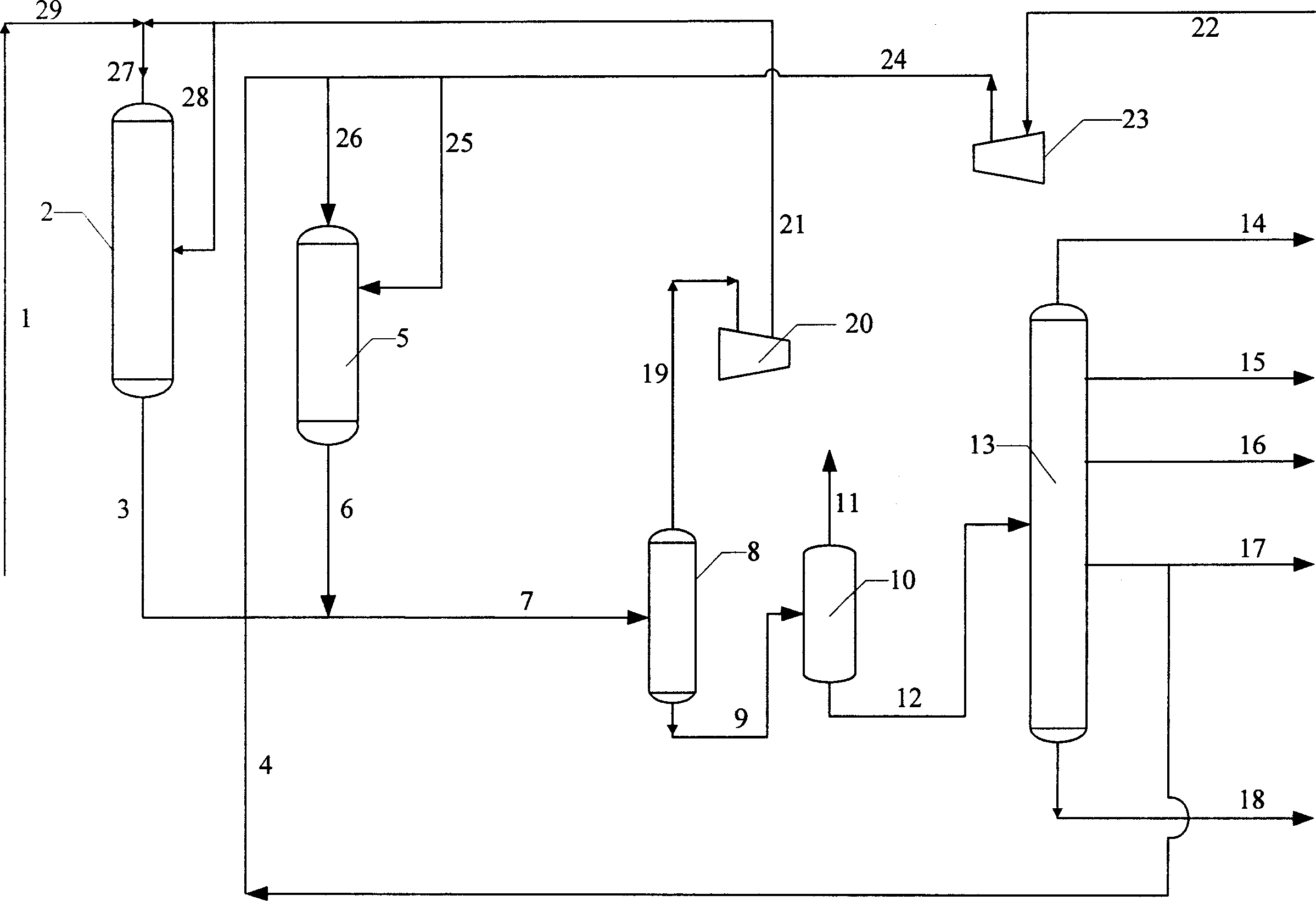

[0046] The process flow of this embodiment is the hydrocracking process of the present invention, that is, the raw material is first contacted with the hydrotreating catalyst, and the light gas oil (distillation range 370-420°C) obtained by separating the hydrotreating reaction effluent is then mixed with the The hydrocracking catalyst is contacted, and the hydrotreating reaction effluent is de-separated together with the hydrocracking reaction effluent.

[0047] According to the program operation with a conversion rate of 40m%, the operating conditions are listed in Table 2; the yield of main products and chemical hydrogen consumption are listed in Table 3; the properties of main products are listed in Table 4. It can be seen from Table 2-4 that the hydrocracking process of the present invention can not only obtain Class II diesel oil and FCC feedstock with a sulfur content lower than 1000ppm, but also have a total space velocity of up to 0.70h -1 , higher than the space velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com