Process for producing chemical industry products and fuel oil from coal tar

A technology of coal tar and chemical products, which is applied in the field of coal tar production of chemical products and fuel oil, and can solve problems such as no industrialization practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

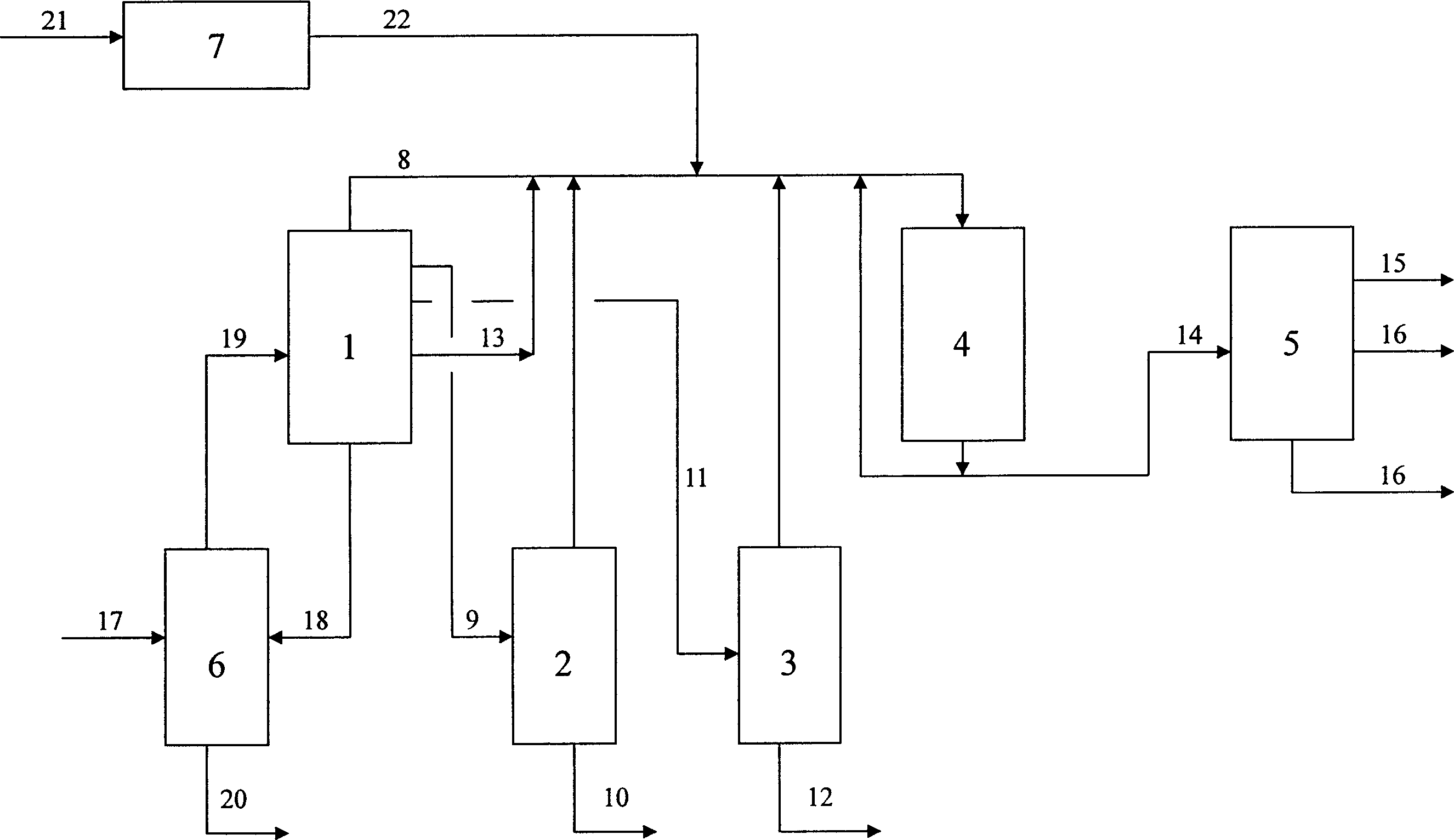

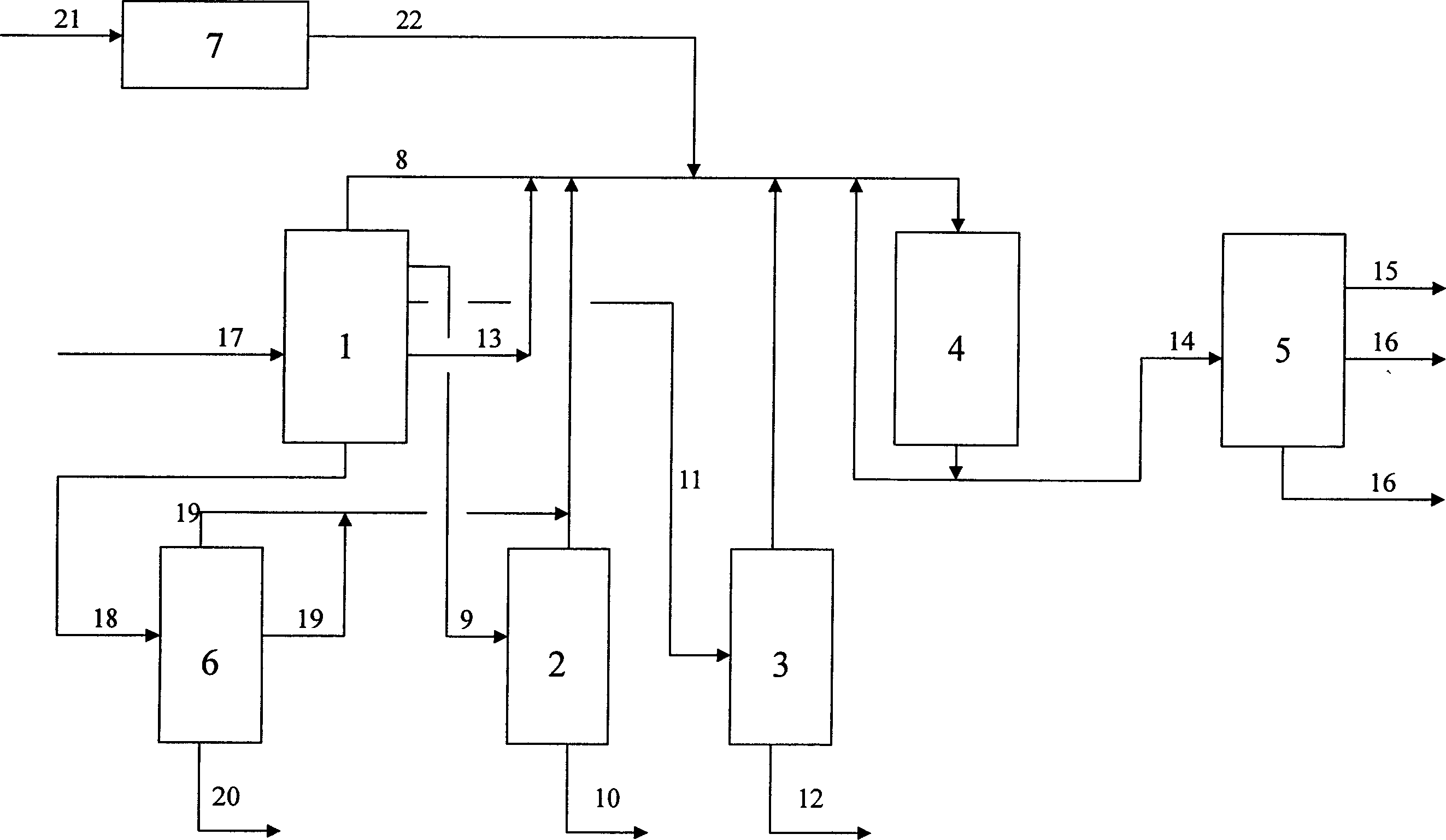

Method used

Image

Examples

Embodiment approach 1

[0034] 1. The raw coal tar is distilled to separate light coal tar less than 360°C and tar pitch greater than 360°C. At the same time, two fractions of 170-210°C and 210-230°C are cut from the light coal tar for production respectively. Industrial phenol and industrial naphthalene;

[0035] II. Mix the remaining fractions from the production of phenol and naphthalene, other light tars and light tars produced by delayed coking as raw materials for hydrorefining, and the hydrorefining catalysts are molybdenum, nickel, arborite or tungsten-molybdenum-nickel type, the carrier is composed of alumina or alumina and titania, the hydrogenation reactor is a typical trickle bed reactor, the catalyst adopts staged loading technology, the operating pressure of the reactor is 8.0Mpa, the reaction temperature is 350°C, and the volume space velocity is 0.5h -1 , the volume ratio of hydrogen to oil is 800-1500, and the above raw materials are hydrotreated to obtain solvent oil, diesel oil or...

Embodiment approach 2

[0057] I. The raw coal tar is distilled to separate light coal tar less than 360°C and tar pitch greater than 360°C. At the same time, two fractions at 210°C and 230°C are cut from the light coal tar to produce industrial phenol and industrial phenol respectively. Naphthalene;

[0058] II. Mix the remaining fractions from the production of phenol and naphthalene, other light tars and light tars produced by delayed coking as raw materials for hydrorefining, and the hydrorefining catalysts are molybdenum, nickel, arborite or tungsten-molybdenum-nickel type, the carrier is composed of alumina or alumina and titania, the hydrogenation reactor is a typical trickle bed reactor, the catalyst adopts staged loading technology, the operating pressure of the reactor is 12Mpa, the reaction temperature is 380°C, and the volume space velocity is 1.2 h -1 , the volume ratio of hydrogen to oil is 1500, and the above raw materials are hydrorefined to obtain solvent oil, diesel oil or light fu...

Embodiment approach 3

[0084] 1. The raw coal tar is distilled to separate light coal tar less than 360°C and tar pitch greater than 360°C. At the same time, two fractions of 170-210°C and 210-230°C are cut from the light coal tar for production respectively. Industrial phenol and industrial naphthalene;

[0085] II. Mix the remaining fractions from the production of phenol and naphthalene, other light tars and light tars produced by delayed coking as raw materials for hydrorefining, and the hydrorefining catalysts are molybdenum, nickel, arborite or tungsten-molybdenum-nickel Type, the carrier is composed of alumina or alumina and titania, the hydrogenation reactor is a typical trickle bed reactor, the catalyst adopts staged loading technology, the operating pressure of the reactor is 10Mpa, the reaction temperature is 360°C, and the volume space velocity is 0.9 h -1 , the volume ratio of hydrogen to oil is 1000, and the above raw materials are hydrorefined to obtain solvent oil, diesel oil or lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com