Technology for producing PVC insulated nylon flexible wire using double machine extruding method

A polyvinyl chloride and nylon sheath technology, applied in the direction of insulated cables, insulated conductors, circuits, etc., can solve the problems of wire surface smoothness, mechanical properties and safety reliability reduction, shortened service life, and loose joints, etc. Improve safety and reliability, prolong service life, and prevent the effect of surface bagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

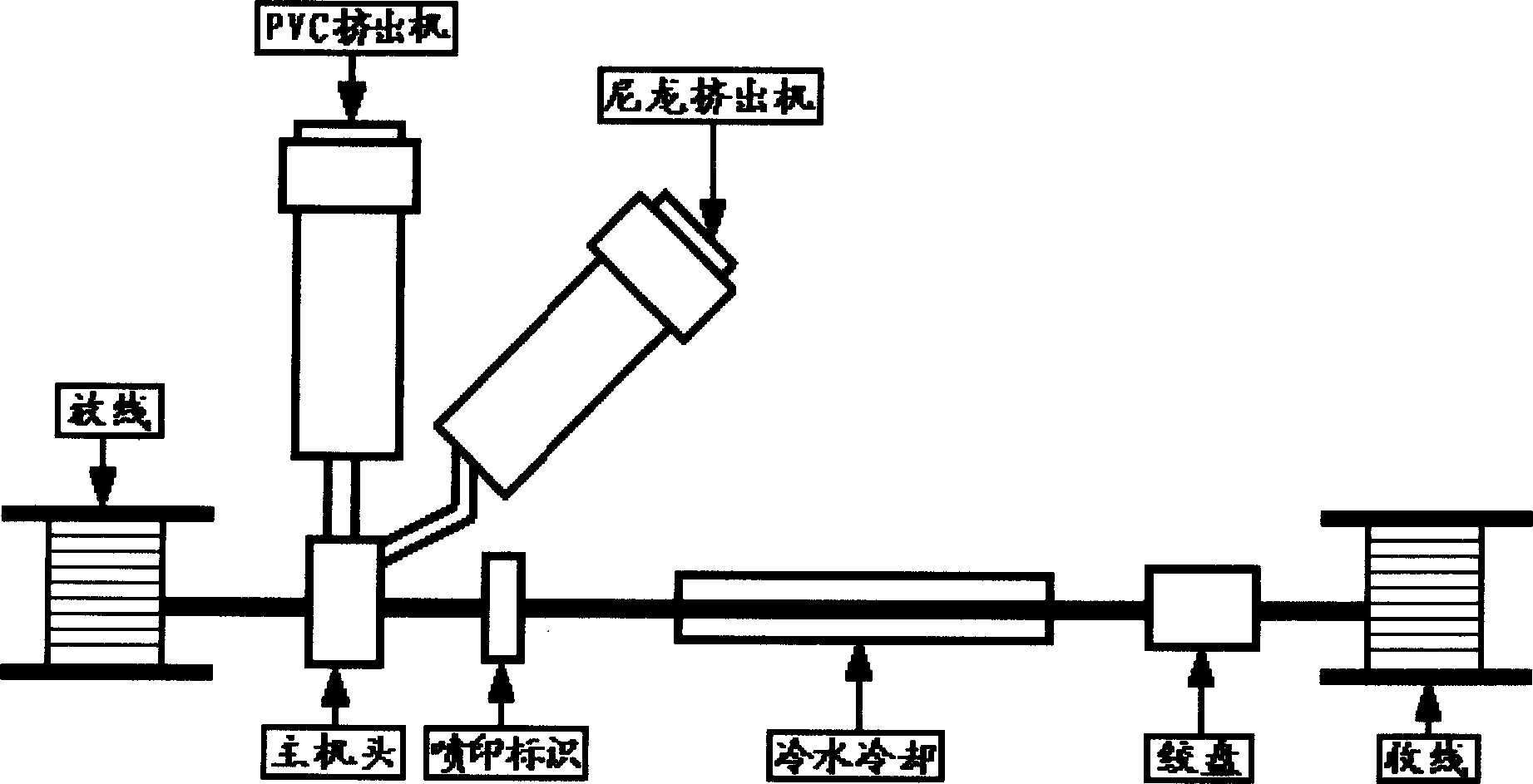

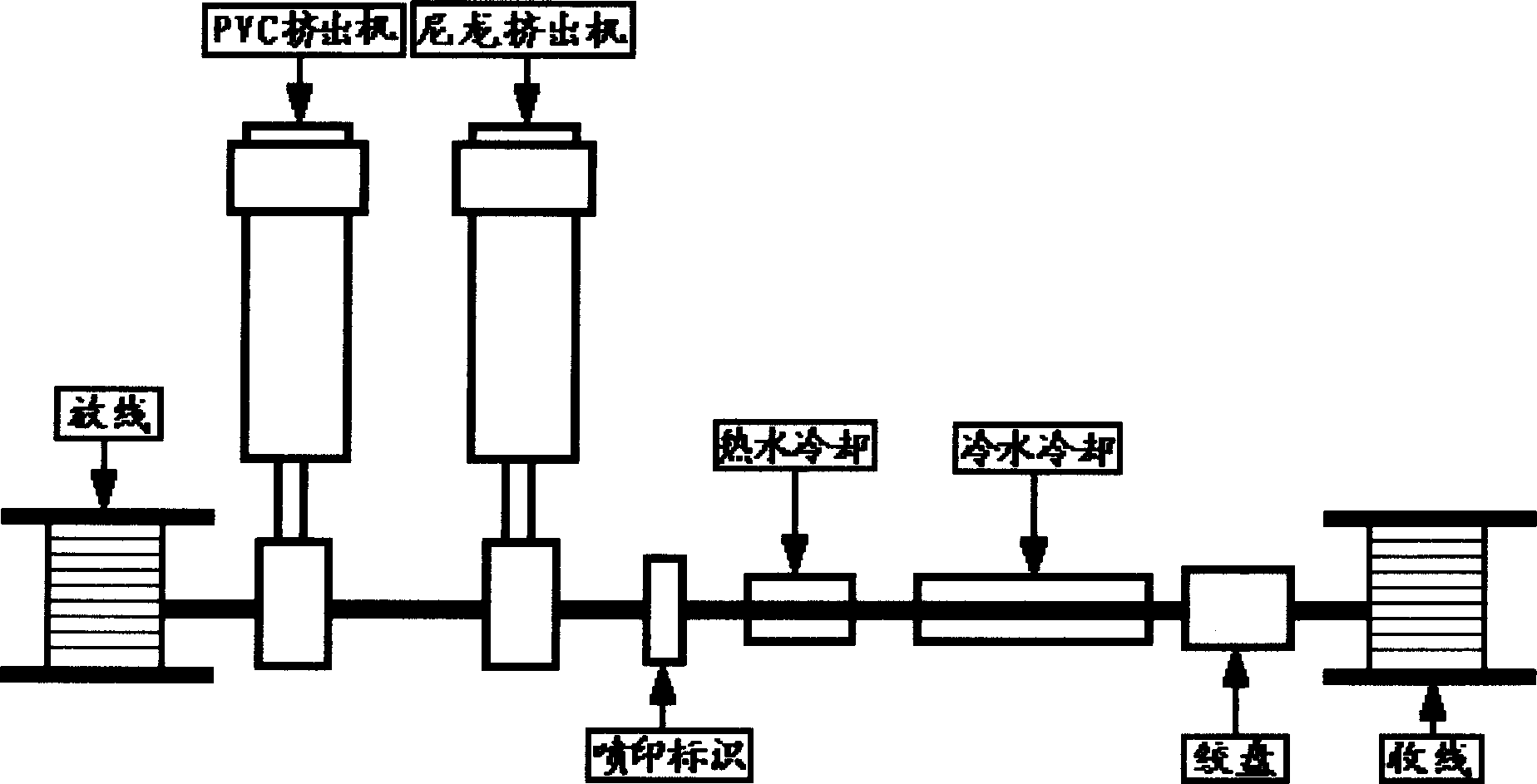

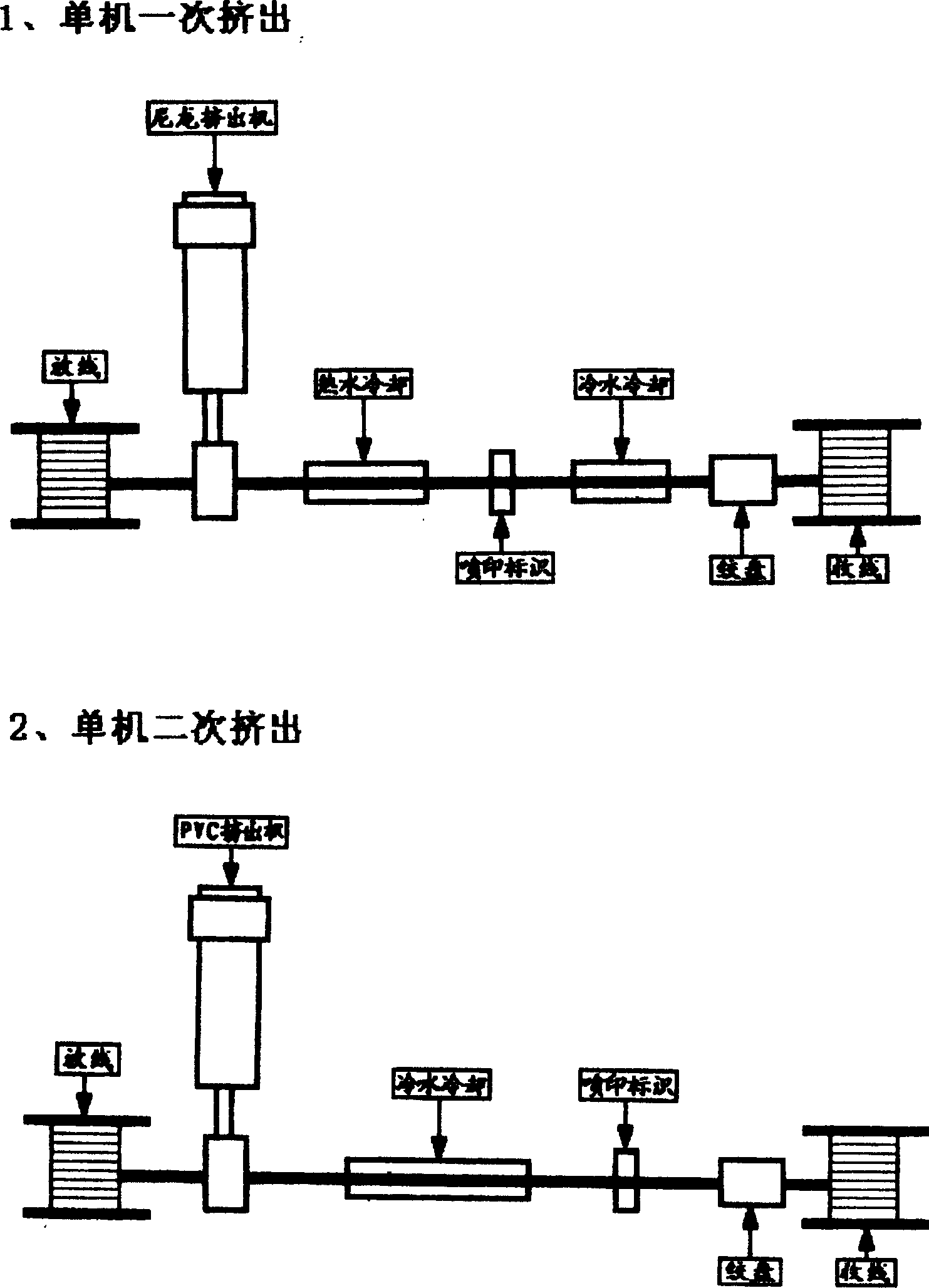

[0019] Such as figure 1 The process of producing polyvinyl chloride insulated nylon sheathed wires by double-machine co-extrusion method shown in the figure, the specific steps are as follows:

[0020] 1. Clean the inner cavity, connectors, shunts, etc. of the nylon extruder, PVC extruder and main engine head, remove the attached glue impurities and coke particles, install the mold and check the surface finish of the mold;

[0021] 2. The pay-off machine releases the wire core, and the wire core enters the host head to preheat, and the wire core should be produced by extrusion extrusion;

[0022] 3. Use a vacuum drying suction machine to dry and transport the nylon material. After drying, the moisture content of the nylon material should not be higher than 0.3%, and the unpacked nylon material should not be exposed to the air for more than 45 minutes;

[0023] 4. Vacuuming inside the nylon extruder, PVC extruder and host head;

[0024] 5. The dried nylon material is sucked i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com