Negative thermal-expansion coefficient adjustable laminated ceramic matrix composite and preparing method thereof

A negative thermal expansion coefficient, composite material technology, applied in ceramic layered products, chemical instruments and methods, layered products, etc., can solve the problems of difficult to control the negative expansion of multiphase materials, difficult to obtain compensation effects, complex sintering process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

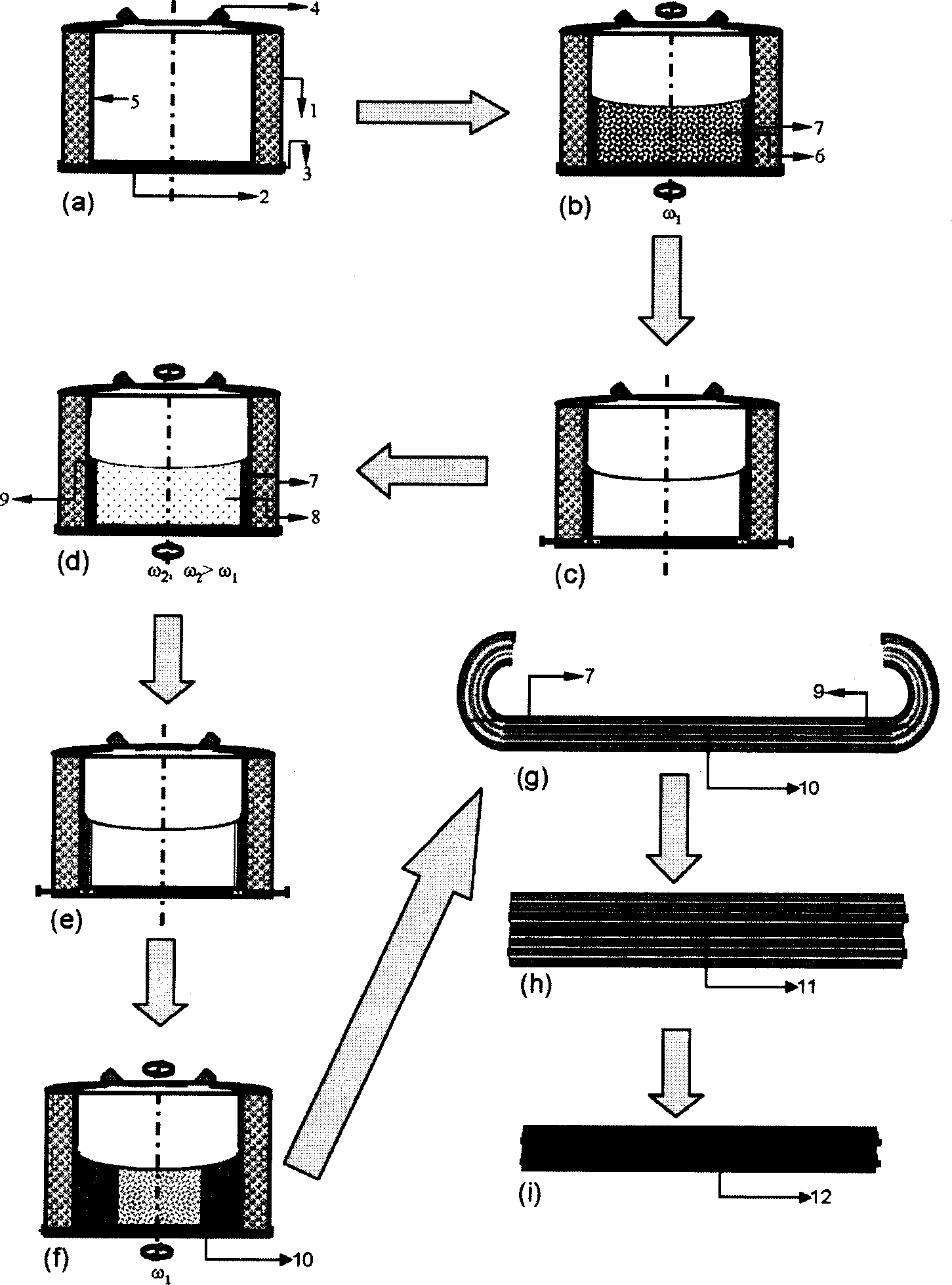

Method used

Image

Examples

Embodiment 1

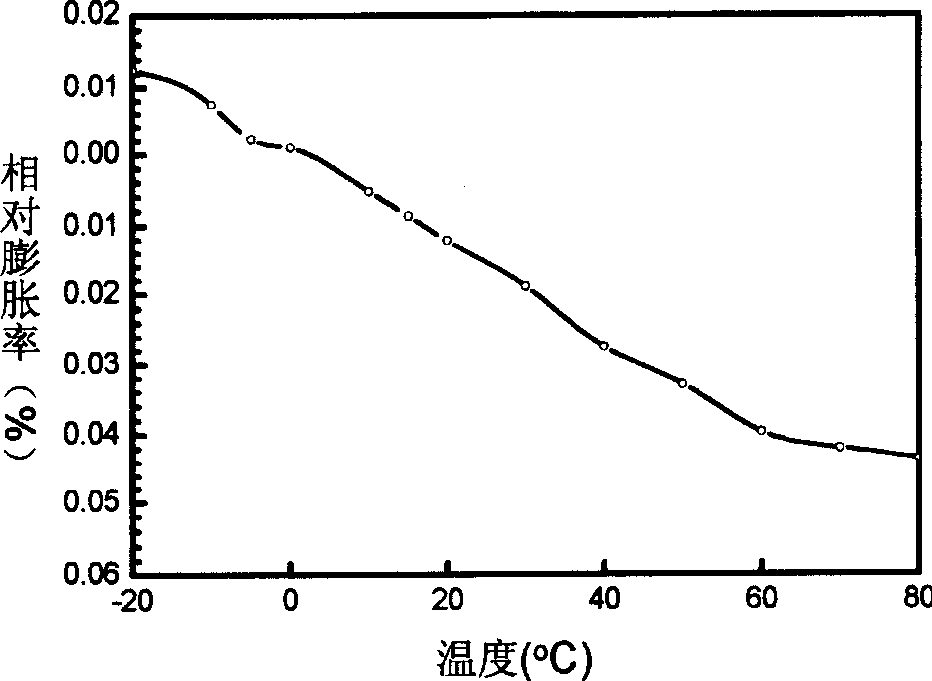

[0025] wxya 2 o 8 -20Vol.% SiO 2 laminated composite ceramic substrate

[0026] Prepare single-phase zirconium tungstate according to the following process: commercially available ZrO(NO 3 ) 2 Configured as 1M ZrO(NO 3 ) 2 solution, and configure 1M ammonia complex (NH 4 ) 6 h 2 W 12 o 40 etc. as precursors, these precursors are uniformly mixed according to the atomic ratio of the metals contained in Zr:W=1.0:2.0, heated in a water bath at 60-80°C with constant stirring, and titrated with 2M acetic acid solution into the mixed precursors until A uniform colloidal precipitate containing W and Zr was completely formed. The resulting colloidal precipitate was washed and dehydrated to form a wet gel. Keep warm at 1100-1150°C for 2-4 hours, then quickly quench to room temperature, mix the obtained product with absolute ethanol and ball mill for 4 hours, repeat the above-mentioned process of calcination and quenching to room temperature 1-2 times, the calcination tempera...

Embodiment 2

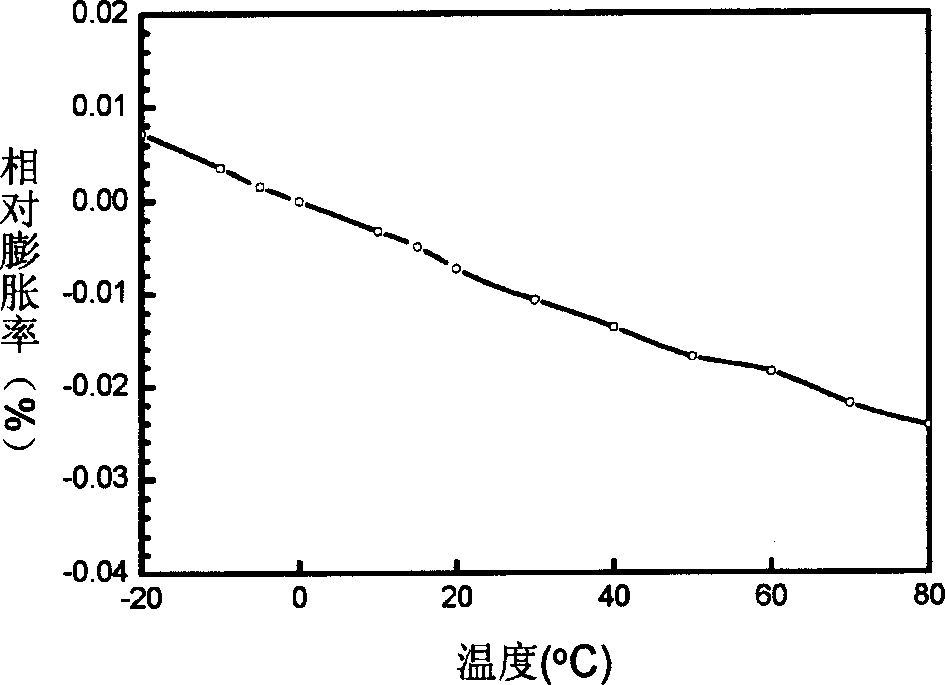

[0031] 0.4mol% Y 2 o 3 -ZrW 2 o 8 / SiO 2 laminated composite ceramic substrate

[0032] Preparation containing 0.4mol% Y 2 o 3 The process of the zirconium tungstate solid solution powder is as follows: with commercially available Y 2 o 3 Dissolved in nitric acid solution, configured as 0.1M Y(NO 3 ) 3 solution, commercially available ZrO(NO 3 ) 2 Configured as 1M ZrO(NO 3 ) 2 solution, and configure 1M ammonia complex (NH 4 ) 6 h 2 W 12 o 40 etc. as precursors, these precursors are uniformly mixed according to the atomic ratio of the metals contained in Y: Zr: W = 0.008: 0.992: 2.0, heated in a water bath at 60-80°C with constant stirring, and titrated with 2M Acetic acid solution until a homogeneous colloidal precipitate containing various metal atoms is completely formed

[0033] With the above preparation containing 0.4mol% Y 2 o 3 Zirconium tungstate solid solution powder and commercially available amorphous silica powder are used as raw materials. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com