High strength austenite steel crystal fining method and miter angle extruding deforming mould

An equal-diameter angular extrusion, austenitic steel technology, applied in the field of alloy steel production, can solve the problems of improving strength, refining grains, limited strength improvement, etc., to achieve the effect of maintaining toughness and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

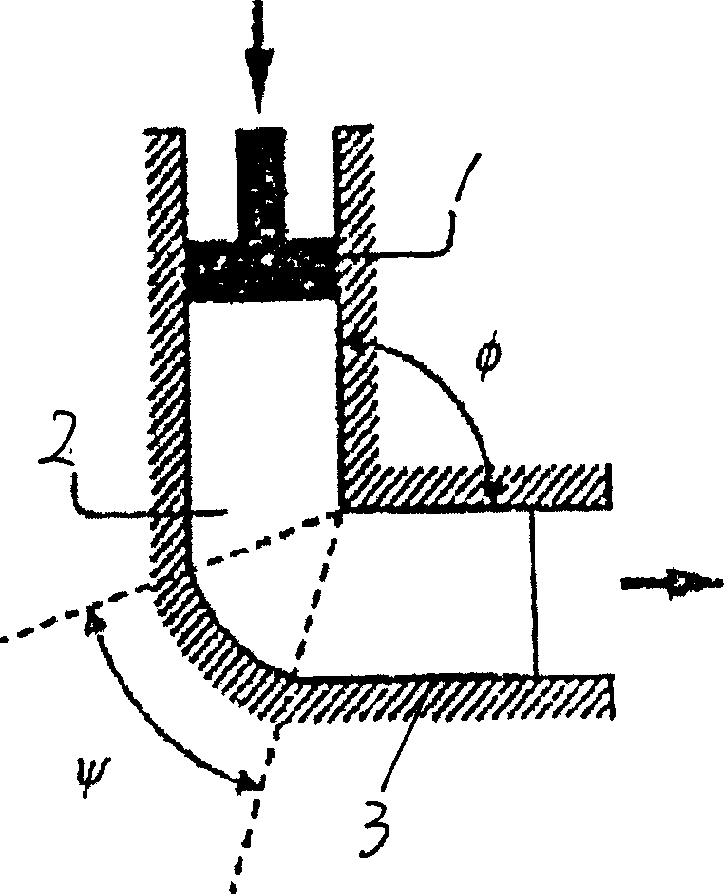

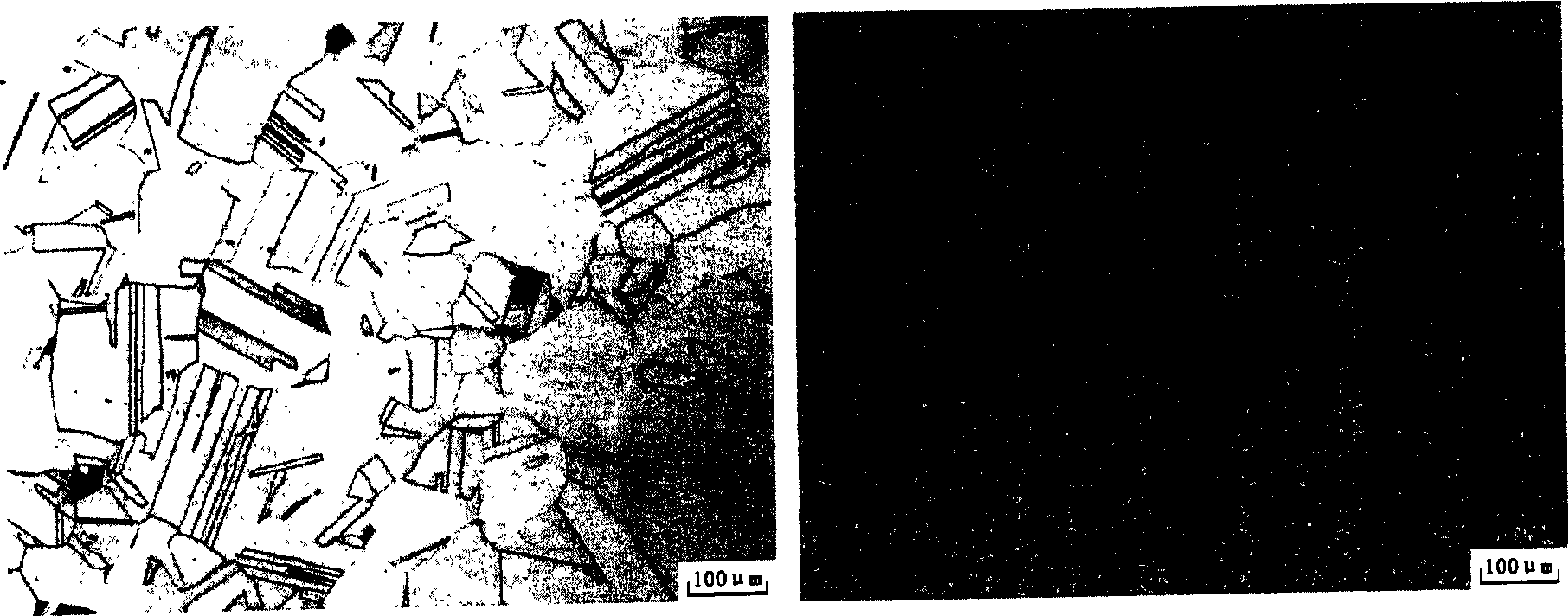

[0013] The material used for the mold of the utility model is ultra-high-strength steel with a grade of T250, and the material used for the extrusion rod is ultra-high-strength steel with a grade of C350. The test material is 0Cr19Ni9N austenitic stainless steel. The process parameters of the mold are shown in Table 1. After one round of equal diameter angular extrusion deformation and annealing at 800-1000°C for 40 minutes, the changes in grain size are shown in Table 2. The comparison table of mechanical properties between Example 1 and the original bar is shown in Table 3. In the above list, serial numbers 1-4 are embodiment 1 of the present invention, and serial numbers 5-6 are original rods.

[0014] Table 1 is the processing parameters of the mold used in Example 1 of the present invention

[0015] serial number

inner corner

Ф°

outside corner

ψ°

Extrusion Rod Yield Strength

Spend

MPa

...

Embodiment 2

[0022] The material used for the mold of the utility model is ultra-high-strength steel with a grade of T250, and the material used for the extrusion rod is ultra-high-strength steel with a grade of C350. The test material is 00Cr18Ni10Mn2 austenitic stainless steel. The process parameters of the mold are shown in Table 4. After one pass of equal-diameter angular extrusion deformation and annealing at 800-1000°C for 40 minutes, the grain size changes are shown in Table 5. The comparison table of mechanical properties between Example 1 and the original bar is shown in Table 6. In the above list, serial numbers 1-4 are embodiment 1 of the present invention, and serial numbers 5-6 are original rods.

[0023] Table 4 is the process parameter of the utility model embodiment 2 mold

[0024] Preface

No

inner corner

Ф°

outside corner

ψ°

Extrusion Rod Yield Strength

MPa

Yield strength of bar

MPa

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com