Controlled cooling method after H-shape steel rolling

A technology for controlled cooling and H-beams, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of inability to meet users, uneven microstructure of cross-section, and unattainable comprehensive mechanical properties and overall service performance of H-beams. , to achieve the effect of enhancing competitiveness, improving comprehensive mechanical properties, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

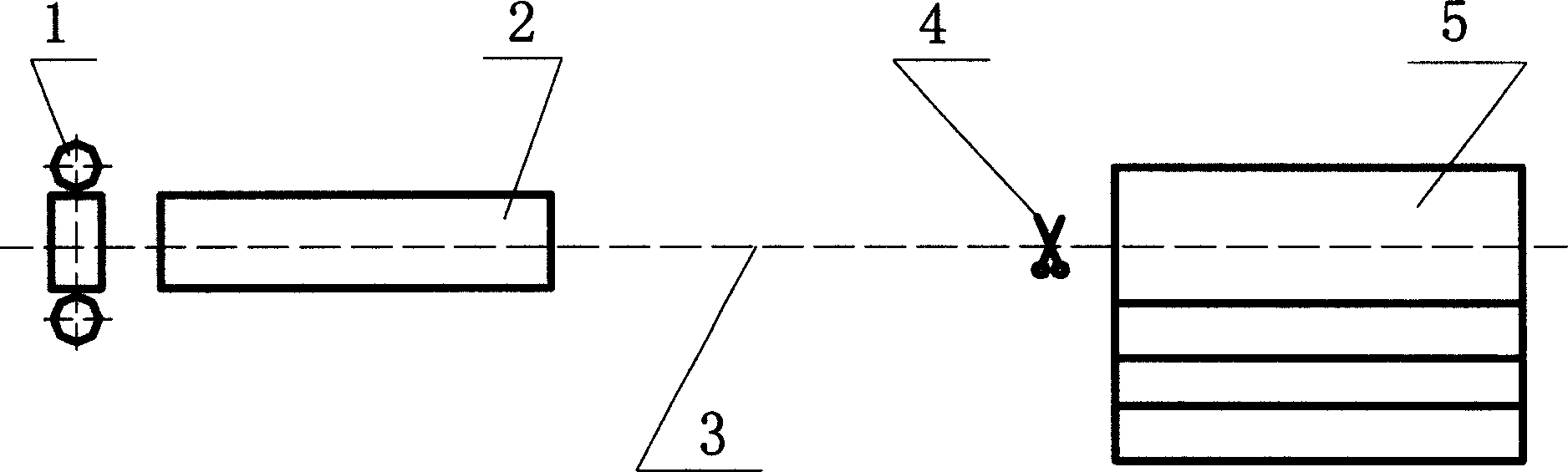

[0016] A set of controlled cooling device is installed behind the H-beam universal rolling mill in a certain factory. The layout of the cooling system is as follows figure 1 As shown, the cooling device adopts the air mist cooling method. The size of the billet used for the rolled H-beam is 300mm×200mm rectangular billet, and the finished size of the H-beam is HM200×150. The billet is first rolled for 5 passes in the two-roll billet mill, then rolled for 3 passes in the universal rough rolling mill unit in the form of UEU, and finally rolled once in the universal finishing mill.

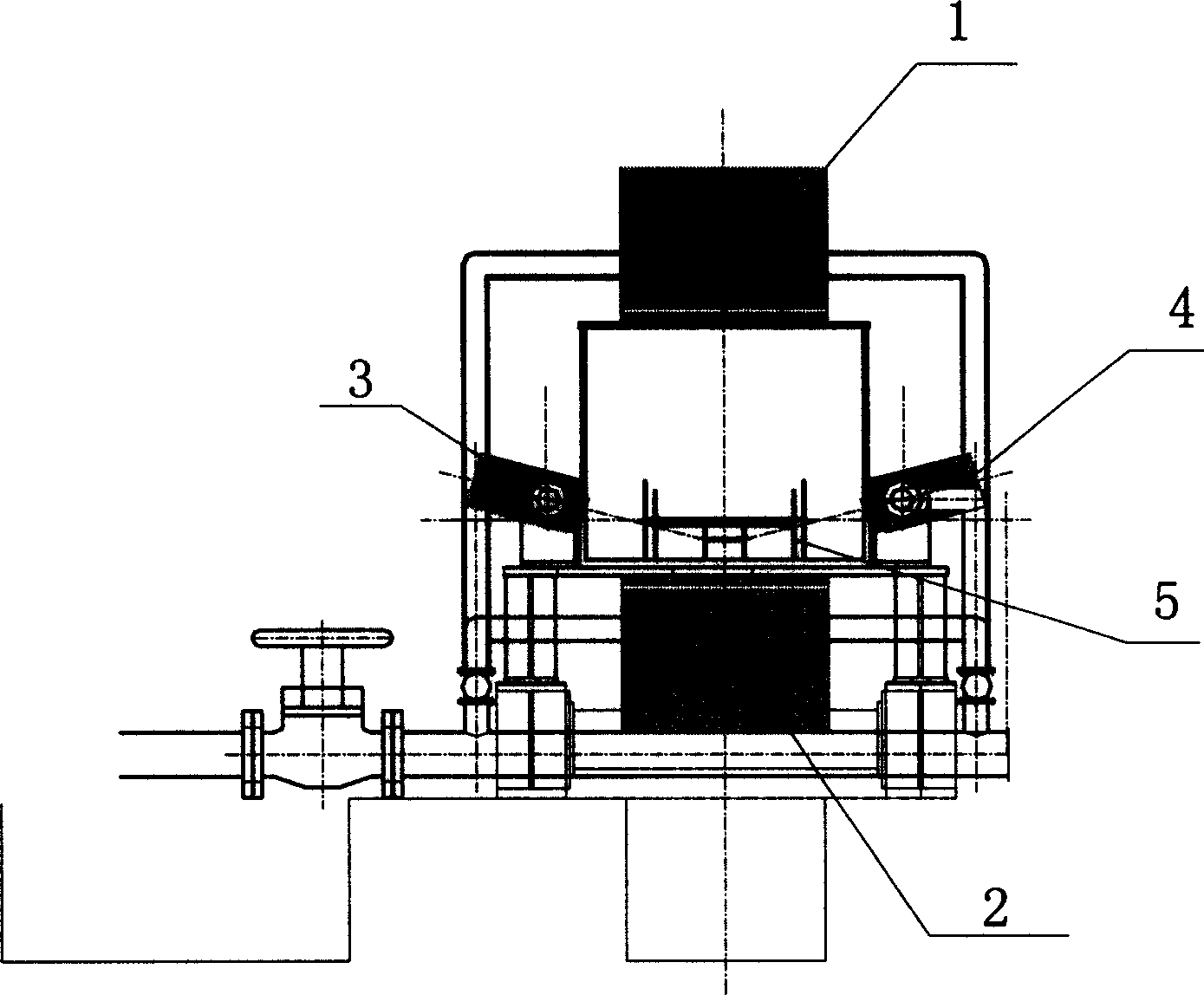

[0017] After the H-shaped steel is rolled, it enters the control cooling device for cooling. The cross-sectional layout of the nozzle in the cooling device is as follows: figure 2 As shown, the upper and lower groups of nozzles are arranged along the vertical direction of the H-shaped steel axis, and the nozzles on both sides form an included angle of about 20°C along the horizontal axis of the H-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com