High-temperature and strong alkali organic silicon antifoamer emulsion composition and preparing method thereof

A technology of emulsion composition and defoamer, which is applied in the direction of foam dispersion/prevention, can solve the problems of prolonged action time of defoamer, difficulty of foam control compound, unsatisfactory use effect, etc., and achieve simplification of emulsification equipment and stability of emulsion And the effect of good shear resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

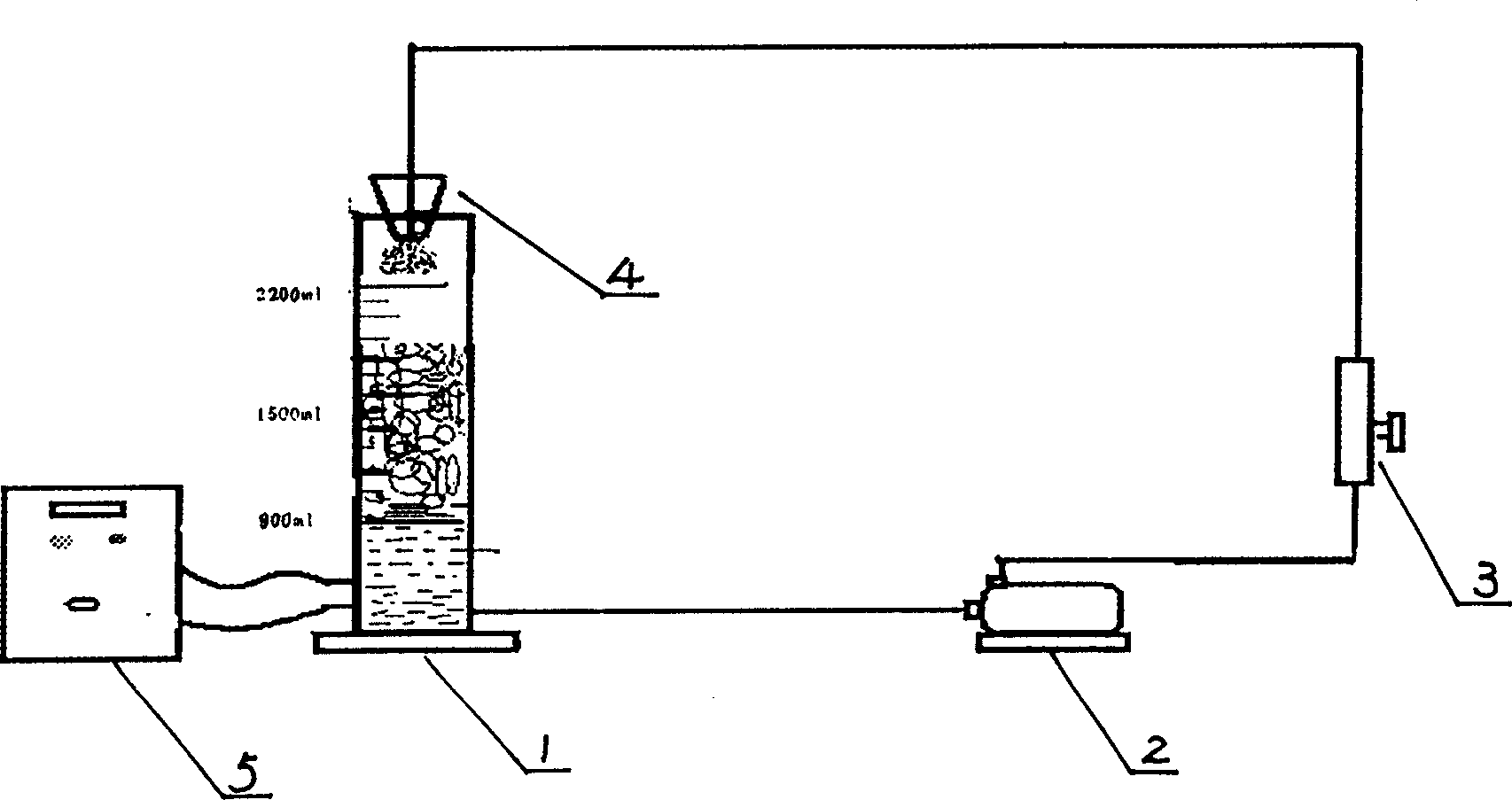

Image

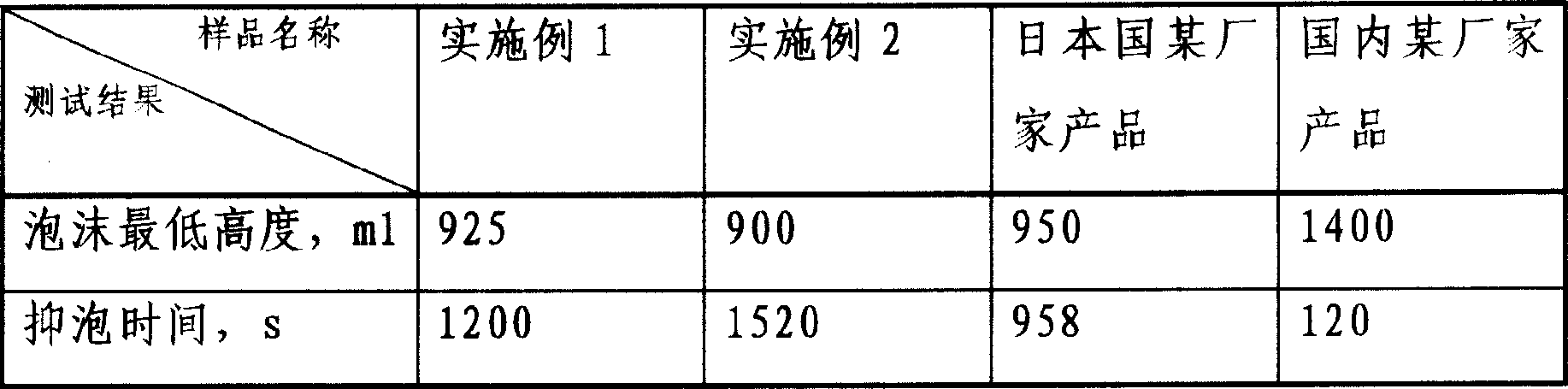

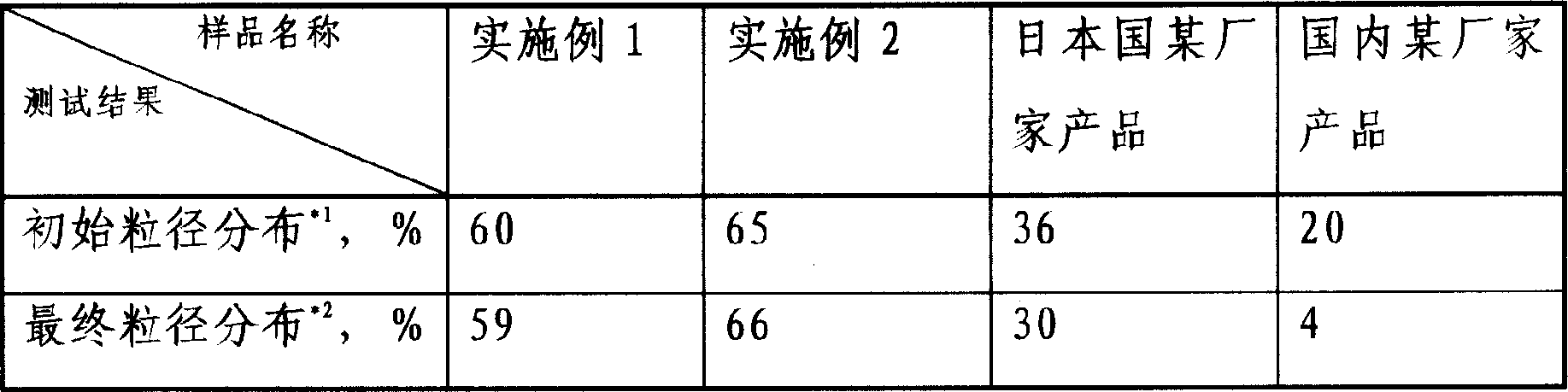

Examples

Embodiment 1

[0043] Preparation of defoamer emulsion composition:

[0044] In a 5L vacuum kneader, add 1750g of trimethylsilyl-terminated polydimethylsiloxane with a viscosity of 150,000cst, 100g of silicon dioxide (Shenyang A-150) and 30g of monomethyltriethoxysilane, and knead fully After making the system uniform, start heating, and when the temperature of the reaction system reaches 135-140°C, add 120g of catalyst to it, keep warm and start vacuuming and maintain a certain degree of vacuum (0.05-0.06MPa). This process lasts for 3.5 hours. The catalyst is prepared by reacting 108g octamethylcyclotetrasiloxane and 12g KOH at 140°C for 15min. Finally, react for another 3 hours at 160° C. and a vacuum of 0.05-0.06 MPa to remove unreacted substances and reaction by-products. Cool to room temperature to obtain a white paste defoamer emulsion composition.

[0045] Emulsion preparation:

[0046] Add powdery 150g polyoxyethylene stearate (40mol) and 200g monoglyceride (molecular distillation...

Embodiment 2

[0050] In a 5L vacuum kneader, add 1750g of trimethylsilyl-terminated polydimethylsiloxane with a viscosity of 300,000cst, 100g of silicon dioxide (Shenyang A-150) and 90g of hexamethyldisiloxane, and knead fully to make After the system is uniform, start heating, and when the temperature of the reaction system reaches 135° C., add 60 g of catalyst to it, keep warm and start vacuuming and maintain a certain degree of vacuum (0.05-0.06 MPa). This process lasts for 8 hours. The catalyst was prepared by reacting 45 g of trimethylsilane-terminated polymerized dimethylsiloxane (1,000 cst) with 5 g of KOH at 140° C. for 15 min. Finally, react for another 0.5 h at 160° C. and a vacuum of 0.05-0.06 MPa to remove unreacted substances and reaction by-products. Cool to room temperature to obtain a white paste foam control composition.

[0051] emulsion preparation

[0052] Add 140g of powdered Tween 60 and 220g of Span 60 to the foam control composition prepared above, knead thoroughly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com