Screen printing apparatus

A technology of screen printing and equipment, applied in screen printing, screen printing machines, printing, etc., can solve problems such as paste leakage and protrusion, and achieve desirable printing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

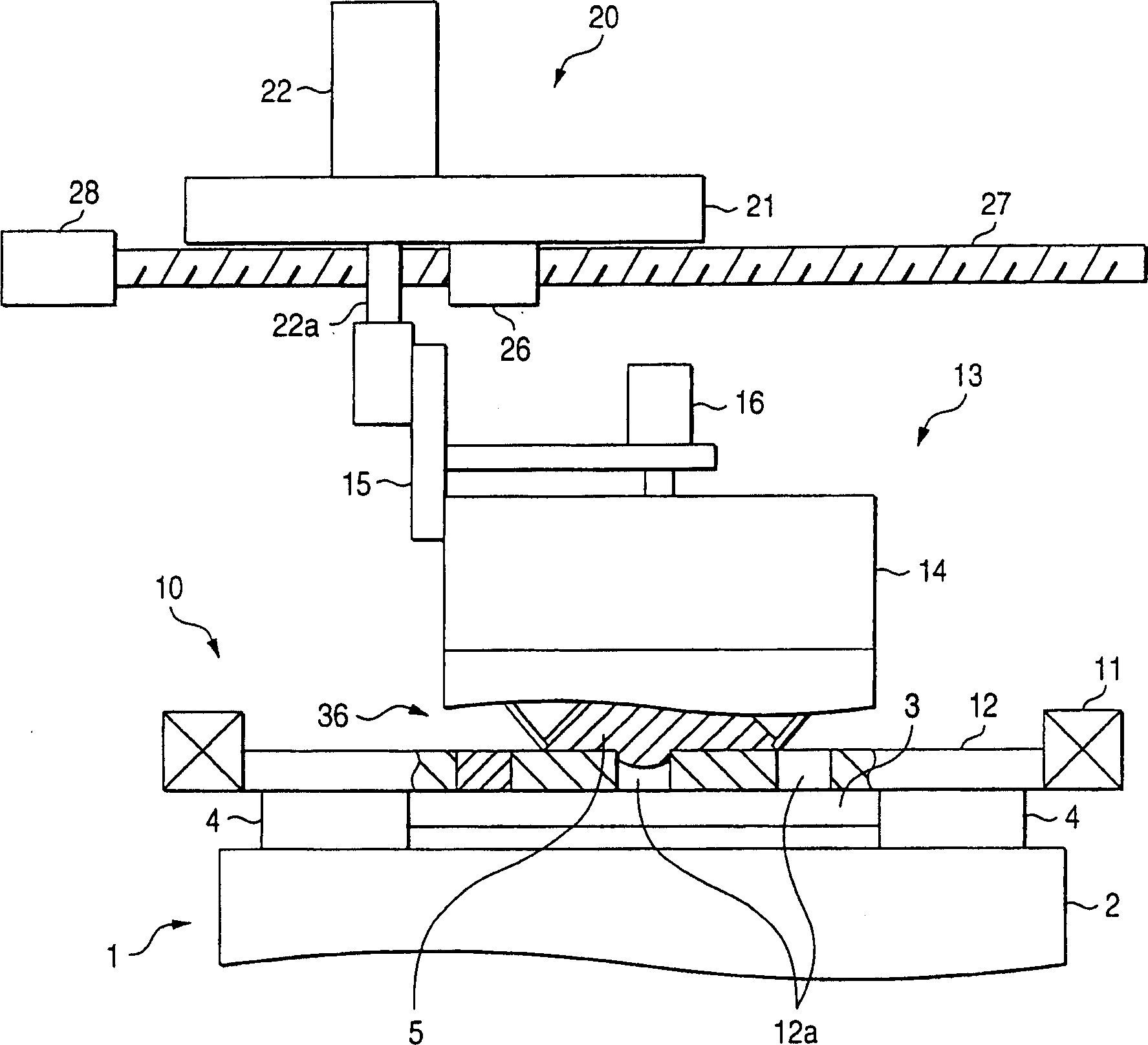

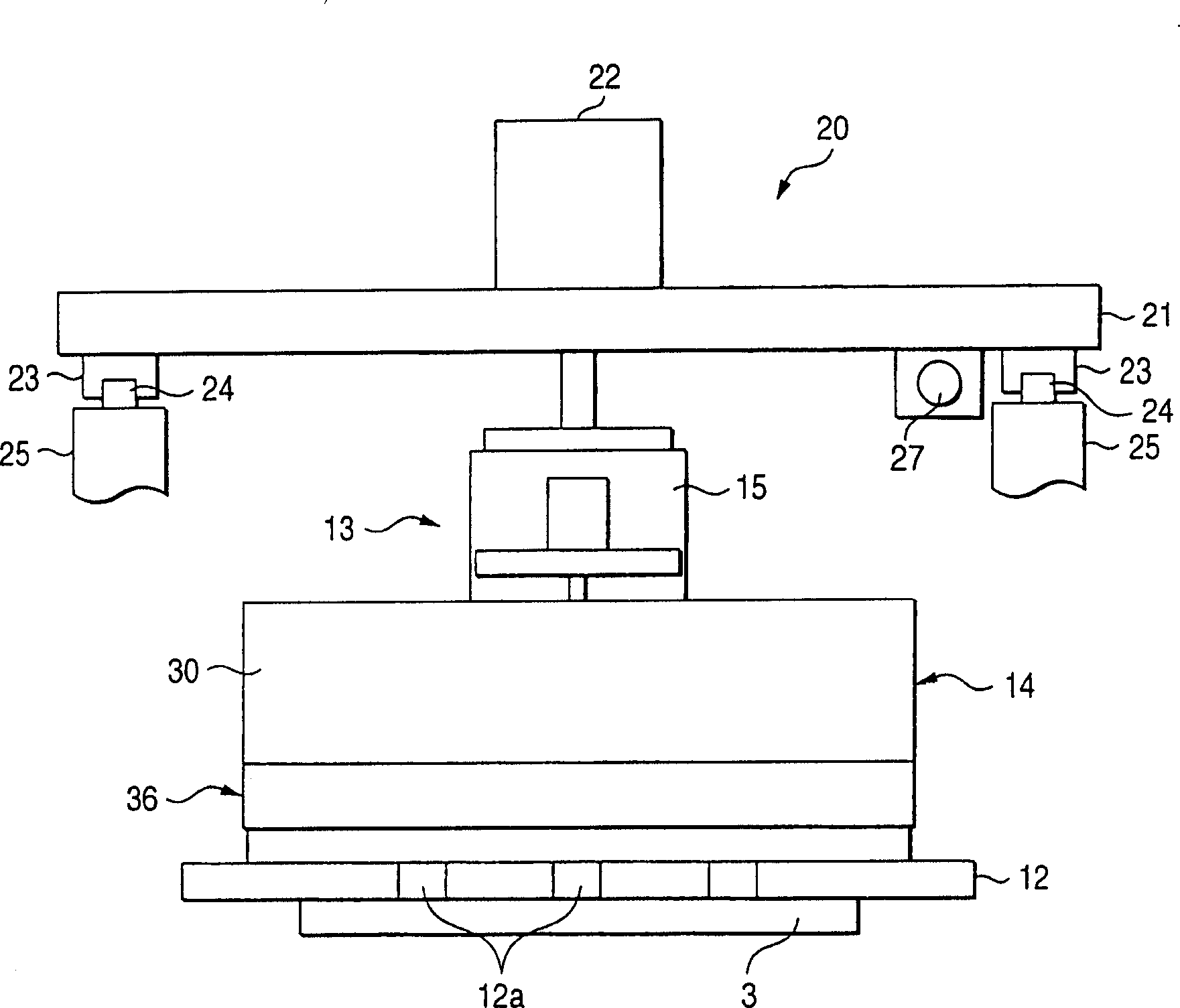

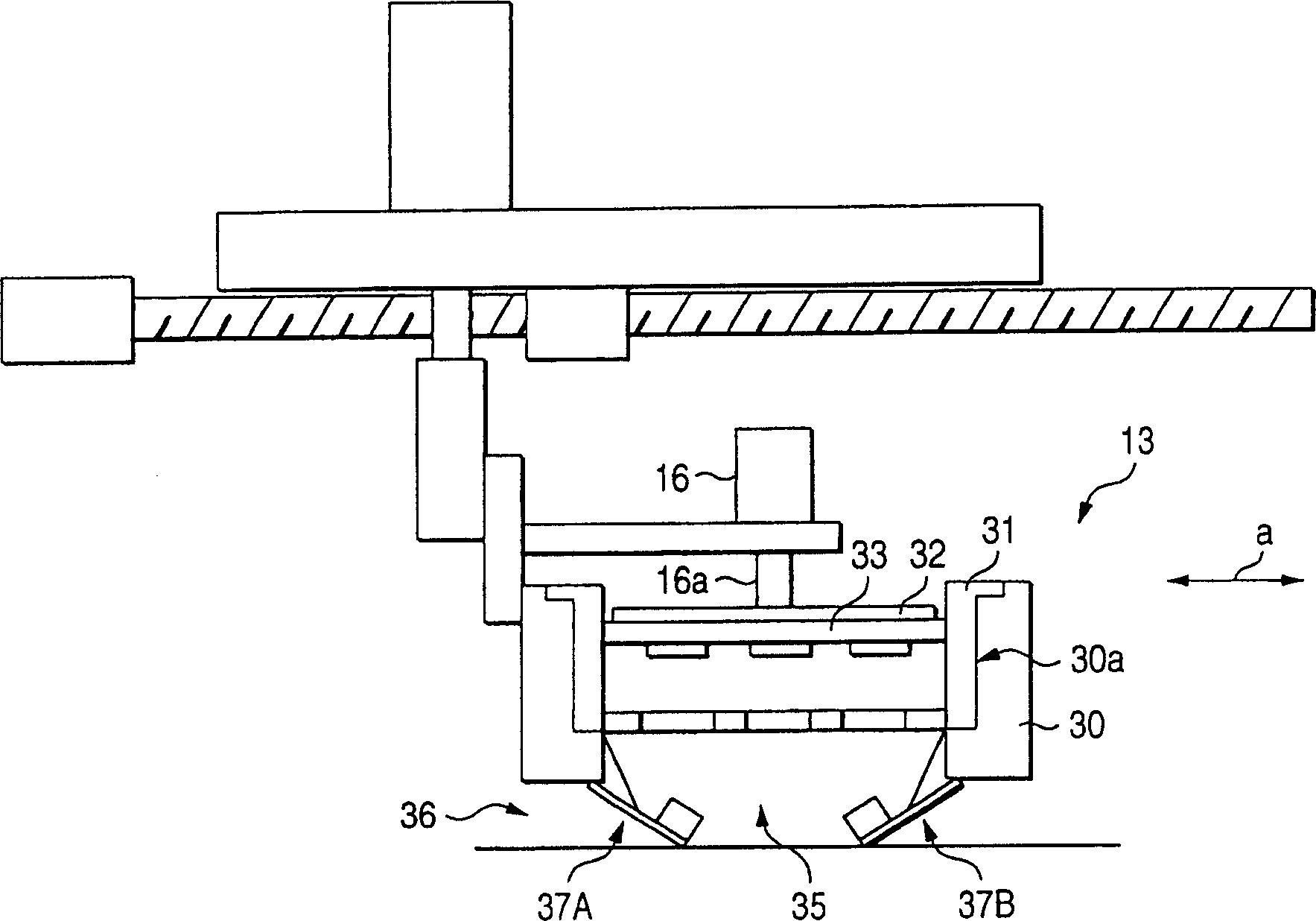

[0016] Next, embodiments of the present invention will be described with reference to these drawings. figure 1 is a front view of a screen printing device according to an embodiment of the present invention, figure 2 is a side view of a screen printing apparatus according to an embodiment of the present invention, image 3 , 4 and 7 are cross-sectional views of a part of an extrusion head of a screen printing apparatus according to an embodiment of the present invention, and FIGS. 5 and 6 are diagrams for explaining operations of the screen printing apparatus according to an embodiment of the present invention.

[0017] First, refer to figure 2 The configuration of this screen printing device will be described. exist figure 1 with 2 In , the positioning section 1 for the substrate is constituted by disposing the substrate holding section 2 on an unillustrated moving table. The substrate 3 to be screen-printed is held by the holder 4 of the substrate holding portion 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com