Semiconductor device and method for manufacturing semiconductor device

A technology of semiconductors and amorphous semiconductors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of being unsuitable for mass production, long time, etc., to reduce display unevenness, high mobility, and avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

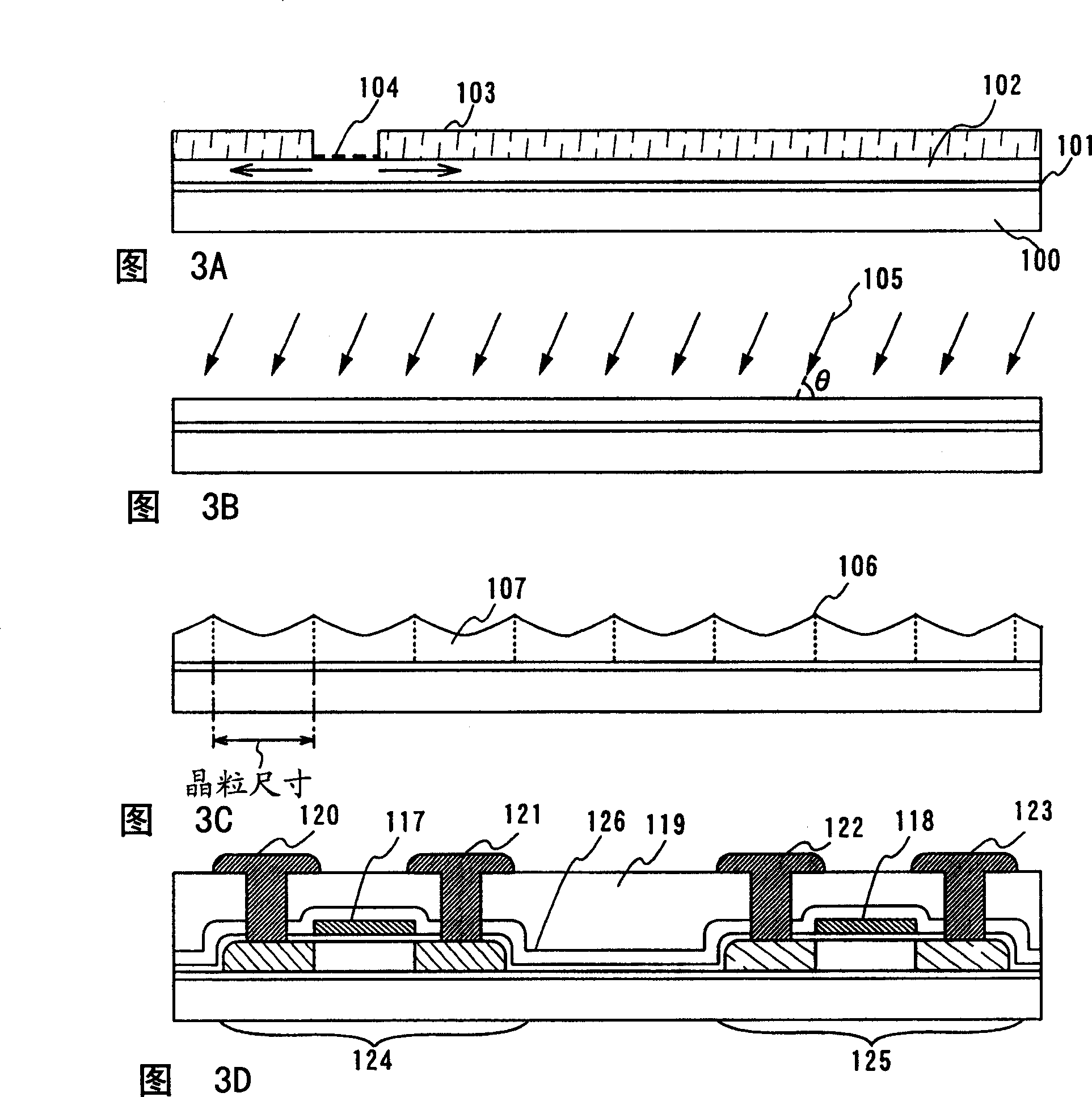

[0230] This example refers to Figures 11A to 11E The principle of ridge formation to maintain order is illustrated.

[0231] Figure 11A Represents the silicon film before being irradiated by pulsed laser light.

[0232] Such as Figure 11B As shown, ridges are formed when irradiating pulsed laser light for the first irradiation. For example, in the case of forming a silicon film to which a metal element promoting crystallization is added and subjected to heat treatment, ridges are formed at positions where grain growth starts from crystal nuclei formed by collision last in the heat treatment. When heat treatment using a metal element is not performed, ridges are formed at random positions.

[0233] Such as Figure 11C As shown, when irradiating pulsed laser light for the second irradiation, scattered light and reflected light (both of which are collectively referred to as diffuse light) increase in laser irradiation due to unevenness generated by ridges on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com