Process for deep dearylation of hydrocarbon oil

A technology for dearomatization and hydrodearomatization, which is applied in the field of hydrotreating hydrocarbon oil, and can solve the problems of not reaching deep dearomatization and low dearomatization depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

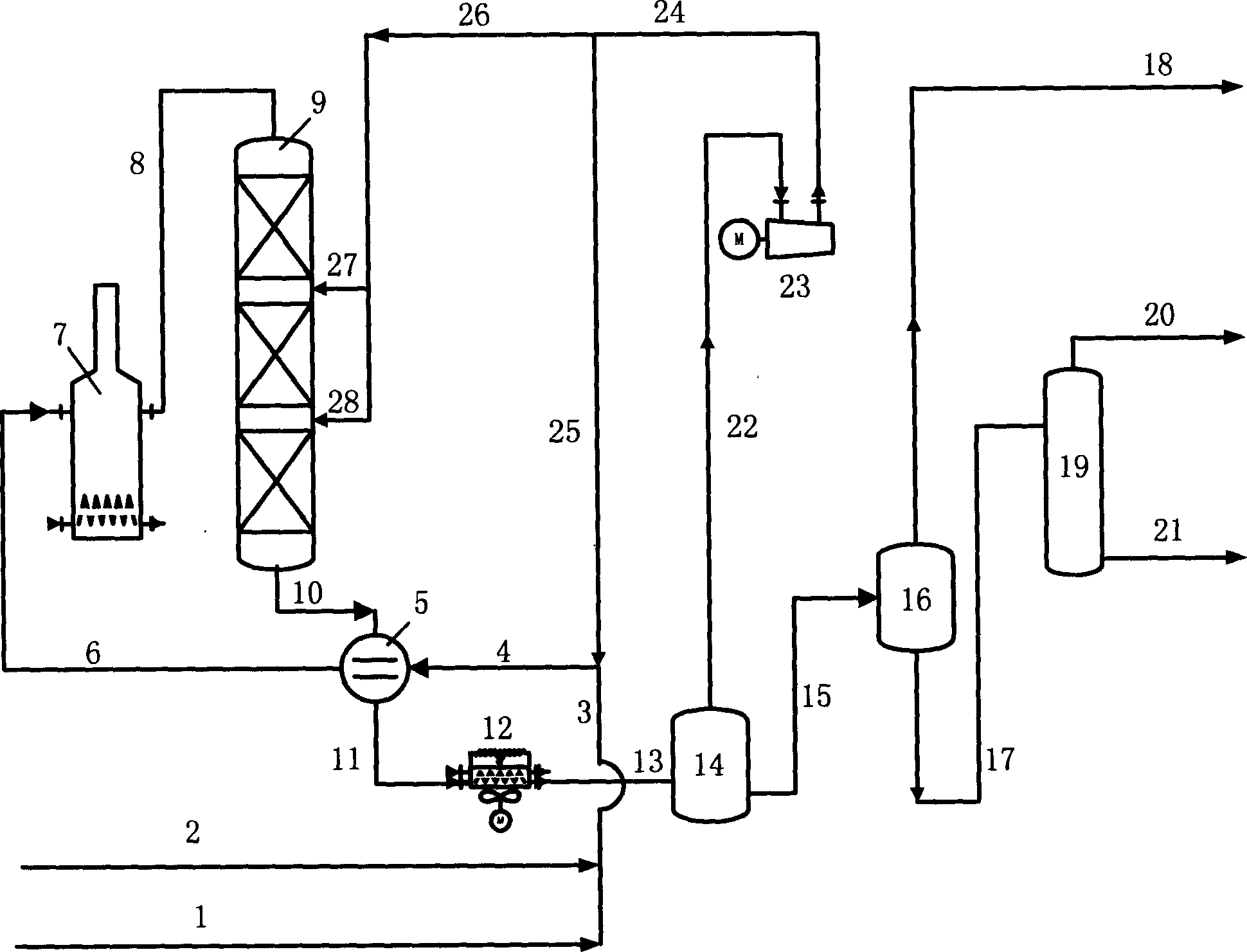

Image

Examples

preparation example Construction

[0018] The preparation method of this catalyst is as follows:

[0019] First, the mesoporous silicon-alumina carrier is shaped, and the formed carrier is dried at 80°C-140°C for 2-10 hours, and then calcined at 400-650°C for 2-10 hours. The platinum and palladium solution used are chloride, chlorate or ammonium salt of platinum and palladium. Immerse for 1-8 hours by saturated impregnation method, then dry at 80°C-140°C for 2-10 hours, and bake at 400-650°C for 2-10 hours. The content of noble metals platinum and palladium is 0.1-10% by weight, and the weight ratio of platinum and palladium is 0.1-10:1.

[0020] When the nature of raw oil is bad, the above process is suitable to be applied in combination with other hydrogenation pretreatment processes.

[0021] The method provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The accompanying drawing is a schematic diagram of a method for deep dearomatizatio...

Embodiment 1

[0036] In this embodiment, solvent naphtha is used as raw material oil, and its properties are shown in Table 1. Carry out the test according to the process flow shown in the accompanying drawing. The test results are shown in Table 2. It can be seen from Table 2 that the aromatics content of the product is less than 0.5% by weight.

Embodiment 2

[0038] In this embodiment, diesel fraction is used as feedstock oil, and its properties are shown in Table 3. Carry out the test according to the process flow shown in the accompanying drawing. The test results are shown in Table 4. It can be seen from Table 4 that the aromatic content of the product is 5.4% by weight.

[0039] Table 1

[0040] Item Raw oil

[0041] Density (20℃), g / cm 3 0.8031

[0042] Refraction, nD 20 1.4478

[0043] Sulfur content, ppm 619

[0044] Nitrogen content, ppm 4

[0045] Total aromatics content, wt% 11.8

[0046] Distillation range (ASTM D-86), ℃

[0047] Initial boiling point 189

[0048] 50% 222

[0049] 90% 231

[0050] Table 2

[0051] Process conditions

[0052] Hydrogen partial pressure 6.4

[0053] Reaction temperature 285

[0054] Hydrogen oil ratio, Nm 3 / m 3 550

[0055] volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com