Metal foil scalding and stamping method using ultraviolet curing adhesive

A technology of metal foil and adhesive, applied in the direction of copying/marking method, printing, etc., can solve the problems of metal foil easy to fall off, insufficient compatibility, and reduce the advantages of screen printing, so as to ensure the bonding strength and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

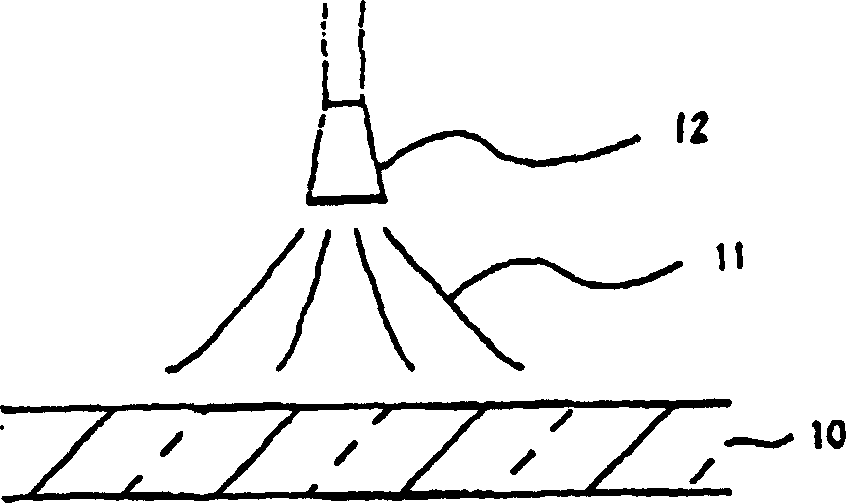

[0047] The first embodiment, that is, the metal foil stamping method as shown in FIG. 1 , includes four steps (1) to (4) as shown below.

[0048] (1) As shown in Figure 1(a), on the surface of the glass container 10, use a silane compound with a boiling point in the range of 10°C to 100°C as the fuel gas, and use its flame 11 on the entire surface of the glass container 10, or a certain Spray locally. This is the silicification flame treatment process.

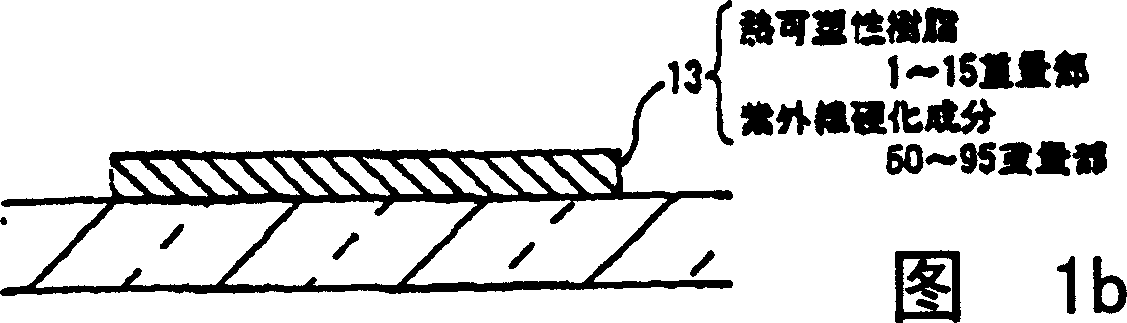

[0049] (2) As shown in FIG. 1( b ), apply an ultraviolet curable adhesive 13 on the surface of the glass container 10 . The ultraviolet curing adhesive 13 contains 1-15 weight units of thermoplastic resin, 50-95 weight units of ultraviolet curing components, and 0.1-10 weight units of photoinitiator. Among them, the main component of the thermoplastic resin is acrylic compound, and the main component of the ultraviolet curing component is epoxy acrylate.

[0050] This is the adhesive application process.

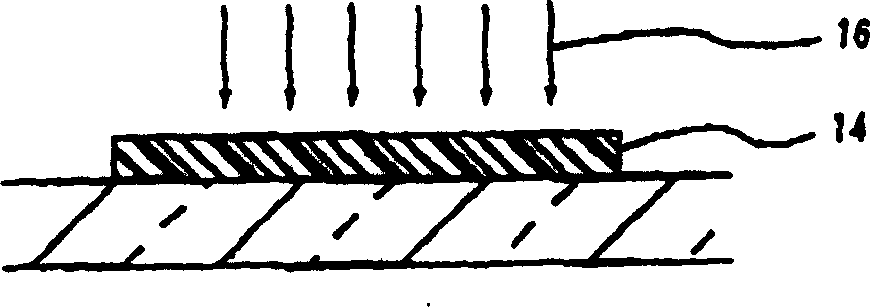

[0051] (3) As sh...

no. 2 Embodiment

[0243] The second embodiment is a metal foil hot stamping method including the following four steps (1) to (4). The standard method is shown in Figure 2.

[0244] (1) As shown in FIG. 2( a ), the ultraviolet curable adhesive 33 is applied to the surface of the glass container 30 .

[0245] (2) As shown in FIG. 2( b ), the surface of the adhesive 33 is irradiated with ultraviolet light 36 to cure it and become a semi-cured state 34 .

[0246] (3) As shown in FIG. 2(c), use a silane compound as a natural gas, and spray the surface of the adhesive 34 in a semi-cured state with its flame.

[0247] (4) As shown in Figure 2(d), hot stamp the metal foil.

[0248] The order of the above four is the order of precedence.

[0249] The points not mentioned in the first embodiment will be described below.

[0250] 1. Gas storage tank

[0251] As shown in Figure 12, the first gas storage tank 132 for storing the silane compound 134 should be equipped with a heating device 136, through ...

example 1

[0264] 1. Implementation of Metal Foil Hot Stamping Method

[0265] ①Silicidation flame treatment process

[0266] use as Figure 16 The portable flame treatment device 170 shown has a flame treatment time of 1 second. The gas is prepared by mixing tetramethylsilane (0.0001 mol%) with a boiling point of 27°C and tetramethylsilane (0.00001 mol%) with a boiling point of 122°C and compressed air.

[0267] ②Preparation and application process of UV-curable adhesive

[0268] In a detachable flask with nitrogen, put 100g of ethyl acetate, 15g of methacrylic acid, 15g of acrylonitrile, 15g of ethylene, and 1g of AIBN. The weight average molecular weight is 60,000). Then, in the container with stirring device, propylene copolymer (solid) 8g (8% by weight), epoxy acrylic acid polymer (weight average molecular weight 2500) 60g, polyfunctional acrylic monomer 7g, monofunctional acrylic monomer 24g, 1g of photoinitiator, put in and stir evenly, and become ultraviolet curable adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com